Surface modification method of spherical aluminum oxide for high-strength epoxy molding compound

A technology of spherical alumina and epoxy molding compound, which is applied in the field of surface modification of spherical alumina for high-strength epoxy molding compound, can solve the problems of high production cost, inactivation of phosphorus-containing curing agent, poor moisture resistance, etc., and achieve The effect of high Shore hardness, high bending strength, and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

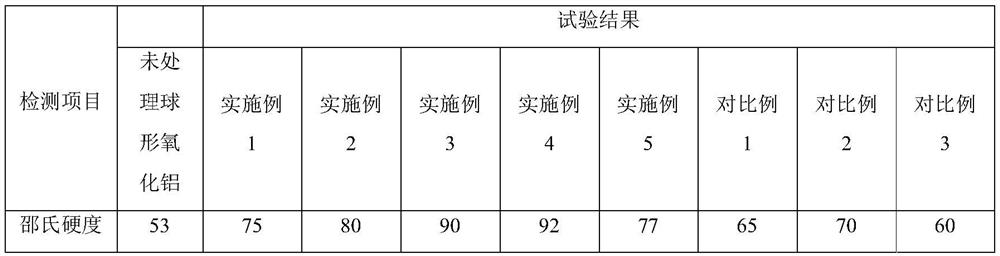

Examples

Embodiment 1

[0028] (1) Spherical alumina hydroxylation: 3 kg of spherical alumina 1kg of 9-11 μm, 100 g of hydrogen peroxide, a mixed solution of pure water 100g, at a temperature of 60 ° C, stirred for 4 hours, filtrate crushing Drying to give 1 kg of hydroxylated alumina.

[0029] (2) Surface modification: 3 kg of hydroxylated alumina is introduced to the powder surface modification machine, and the spray is added to KBM 573 7G, a acetic acid 0.1 g, pure water 14g, a mixture of isopropyl alcohol 7g, a thermal flow field at 110 ° C Mix for 1 hour.

[0030] (3) Heat treatment: 1 kg of alumina after surface modification is placed in a muffle, and heat treatment at 300 ° C for 6 hours to give alumina for 1 kg of surface heat treatment.

Embodiment 2

[0032] (1) Spherical alumina hydroxylation: 9-11 μm of spherical alumina 1 kg was put into a stirrer, and 100 g of hydrogen peroxide, a mixed solution of pure water 100 g, under 60 ° C, stirred for 4 hours, filtration Dry crushing to give 1 kg of hydroxylated alumina.

[0033] (1) Surface modification: Putting step (2) hydroxylated alumina 1 kg into a stirred tank, and sprayed into A18717 g, acetic acid 0.1 g, pure water 14g, a mixture of isopropyl alcohol 7g, mixed under 110 ° C for 1 hour.

[0034] (1) Heat treatment: 1 kg of alumina after surface modification is placed in a muffle furnace, and heat treatment at 300 ° C for 6 hours to give 1 kg of surface heat treatment alumina.

Embodiment 3

[0036] (1) Spherical alumina hydroxylation: 9-11 μm of spherical alumina 1 kg is administered in a stirrer, and a mixed solution of hydrogen peroxide 100g, pure water 100 g, at 80 ° C, stirred for 4 hours, filtration Dry crushing to give 1 kg of hydroxylated alumina.

[0037] (2) Surface modification: 3 kg of hydroxylated alumina in the stirrer is added to the stirred tank, and a double amino group A178 7G, a acetic acid is 0.1 g, pure water 14g, and a mixture of 7 g of isopropyl alcohol is added in a spray. It was mixed under 110 ° C for 1 hour.

[0038] (3) Heat treatment: 1 kg of alumina after surface modification is placed in a muffle furnace, and heat treatment at 300 ° C for 6 hours to obtain 1 kg of surface heat treatment alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com