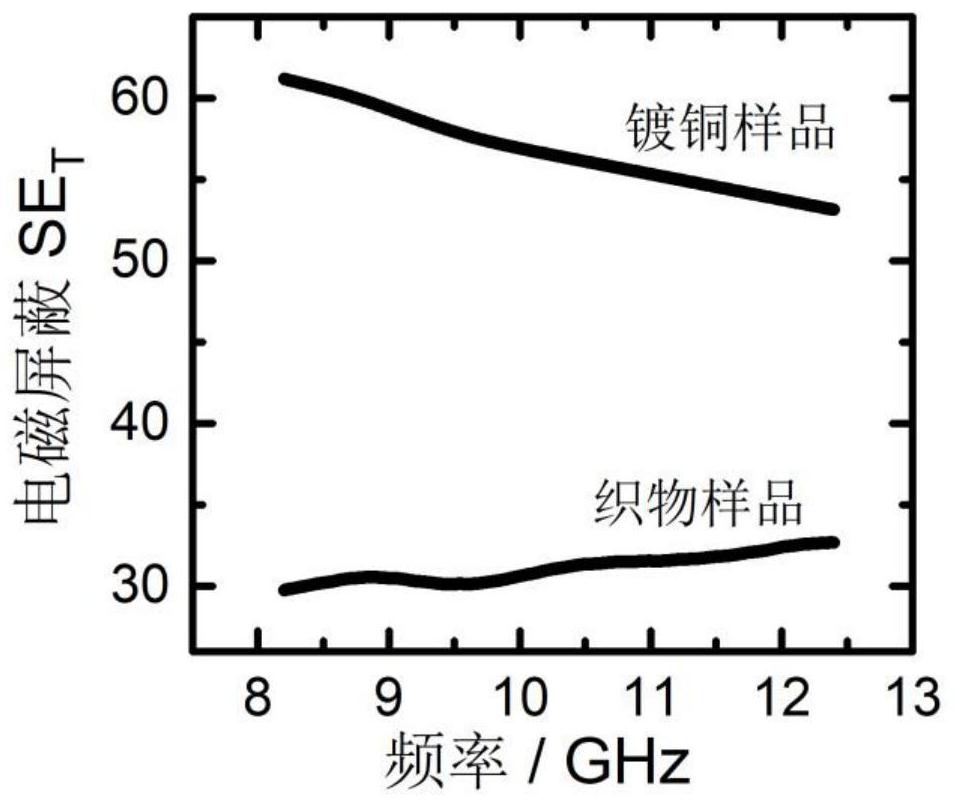

Preparation method of copper-coated carbon fabric electromagnetic shielding material

An electromagnetic shielding material, copper-coated carbon technology, applied in shielding materials, magnetic field/electric field shielding, carbon fiber and other directions, can solve the problems of restricting widespread use, increasing the complexity of the preparation process, etc., to reduce production costs, good flexibility, mild response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A copper-plated carbon fabric electromagnetic shielding material and a preparation method thereof of the present invention comprise the following steps:

[0031] Step 1, ultrasonically clean the 2cm×3cm carbon fabric in 10% dilute hydrochloric acid, deionized water, acetone and ethanol in sequence, take it out and dry it for 12 hours;

[0032] Step 2, soak the carbon fabric obtained in step 1 into a solution of 0.01 g of dopamine hydrochloride dissolved in 5 mL of Tris-HCl.

[0033] Step 3, add 7.31g of ethylenediaminetetraacetic acid into 120mL of deionized water, add potassium hydroxide to adjust the pH to 5.8 while stirring, and the solution is clear and transparent;

[0034] Step 4, respectively dissolving 4.26g copper chloride dihydrate and 3.09g boric acid in deionized water, stirring until clear and transparent, then mixing, then adding the EDTA solution obtained in step 3 into the mixed solution and stirring evenly;

[0035] Step 5, preparing a 1 mol / L potassiu...

Embodiment 2

[0039] In this embodiment, in step 7, stirring was continued for 1 h under heating, and other steps and parameters were the same as in embodiment 1.

Embodiment 3

[0041] In this embodiment, in step 7, stirring was continued for 1.5 h under heating, and other steps and parameters were the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com