Neutral zinc-manganese secondary battery and electrolyte

A secondary battery and electrolyte technology, applied in the field of batteries and zinc-manganese secondary batteries, can solve the problems of battery capacity decay, heavy corrosion of zinc negative electrode, low battery specific capacity, etc., and achieve the effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

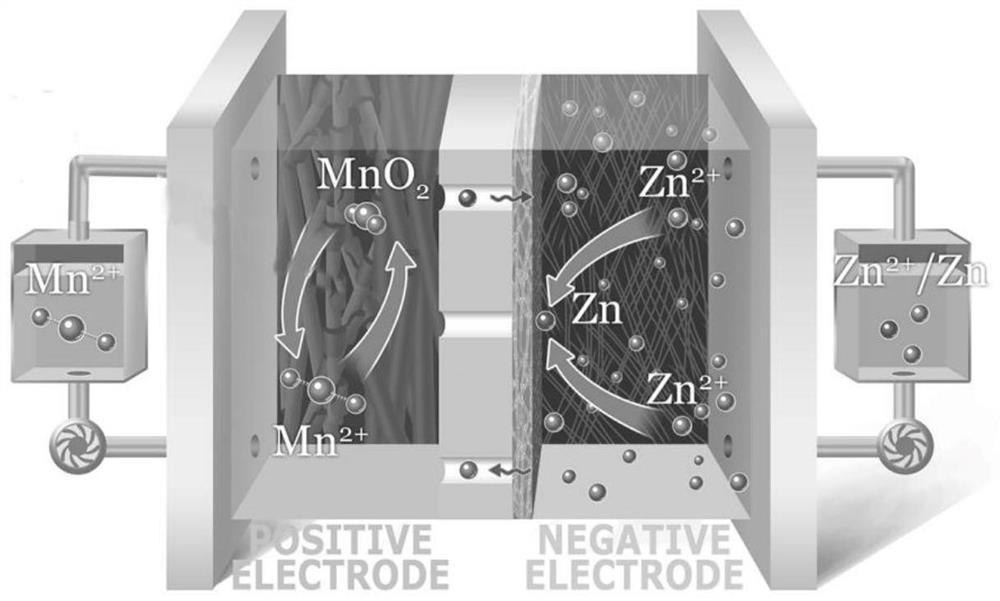

[0047]Examples 1-24 are a zinc manganese liquid flow battery assembled in a single battery, and the single battery sequentially includes a positive electrode end plate, a positive electrode fluid, a carbon felt positive electrode having a liquid flow frame, a liquid flow frame. Felt negatives, negative electrode concentration fluids, negative electrode plates, electrolytic liquid tanks and pumps with positive, negative electrolytes. Electrolytic flow rate is 10 ml / min, charge current is 40mA / cm2The cutoff condition of the battery is time-off, and the charging deadline is 10 ~ 30mins, the safety voltage is set to 2.3V, the discharge voltage is 0.1V.

[0048]Electrode area 48cm2The carbon felt has a thickness of 5 mm, a compression ratio of 30%.

[0049]

[0050]

[0051]

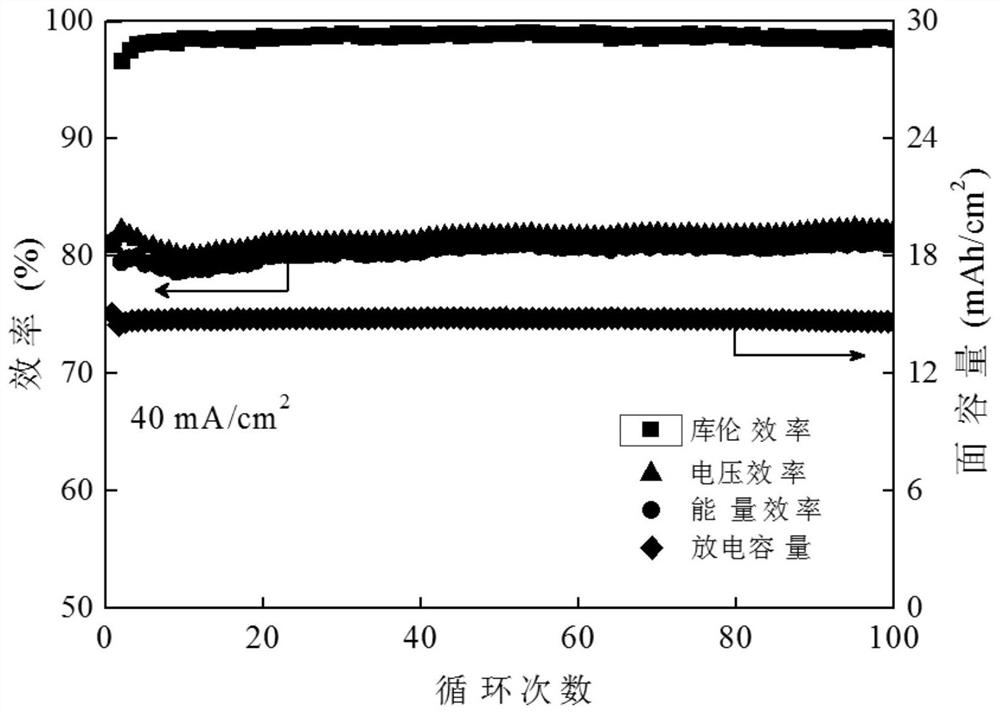

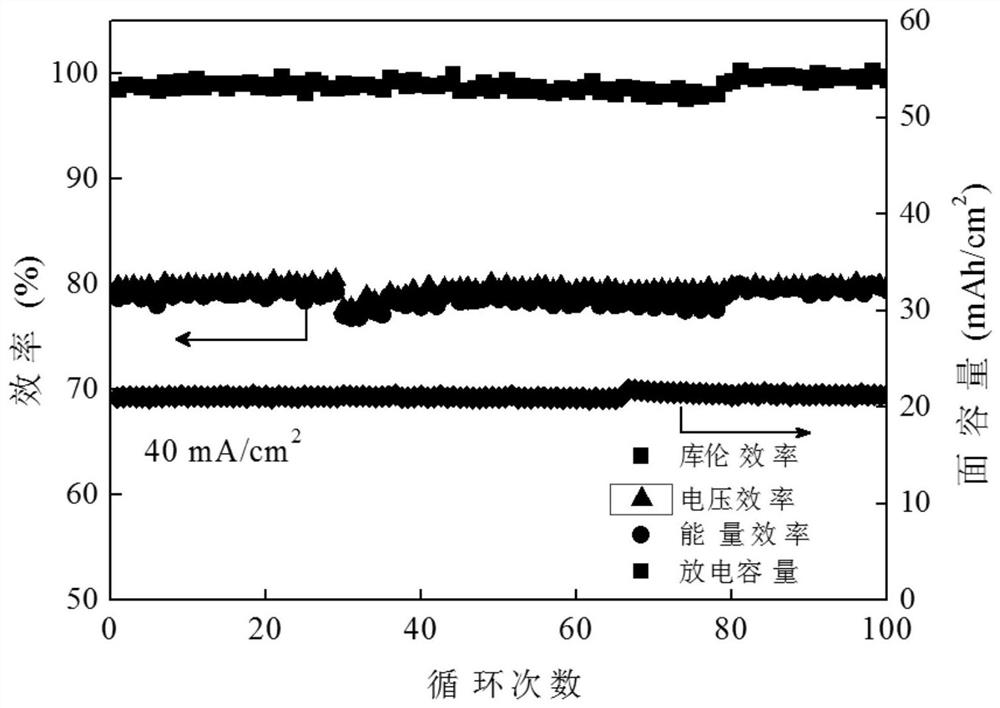

[0052]image 3 (Example 2) is a circulating performance-capacity retention ratio of the battery under optimal conditions (the ratio of acetate anion and manganese ions is 4: 1, 1m zinc ion and manganese ion concentration) batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com