Dichloromethane waste gas treatment equipment and method

A technology for waste gas treatment equipment and dichloromethane, which is applied in gas treatment, separation methods, chemical instruments and methods, etc. It can solve the problems of low service life of activated carbon adsorption equipment, easy generation of dioxins in combustion methods, and high energy consumption. , to achieve good physical and chemical stability, long service life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

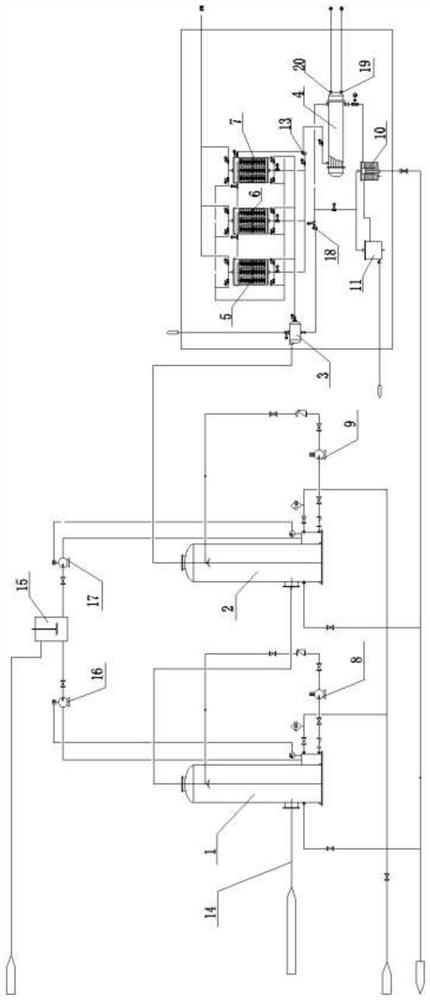

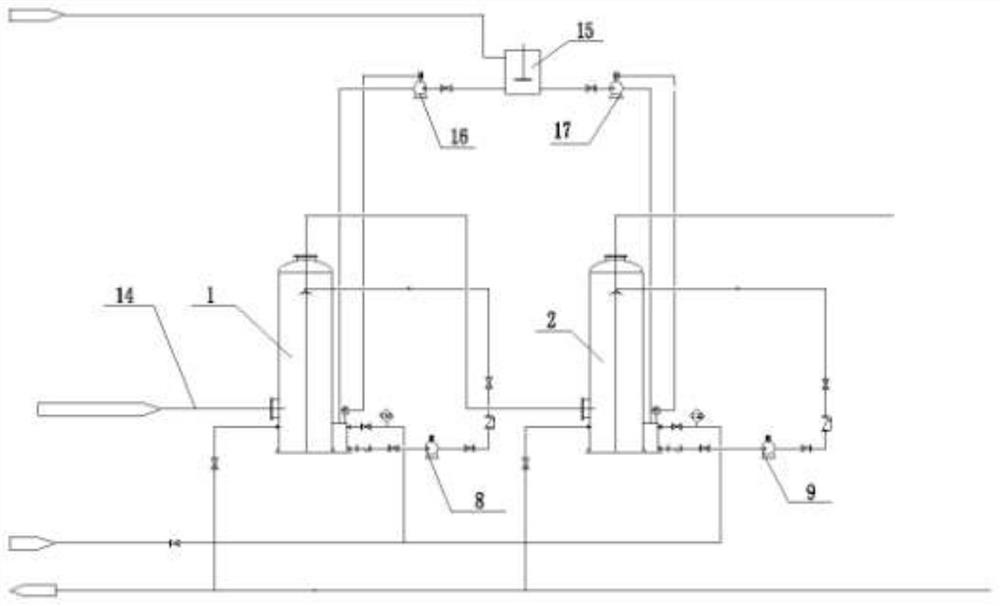

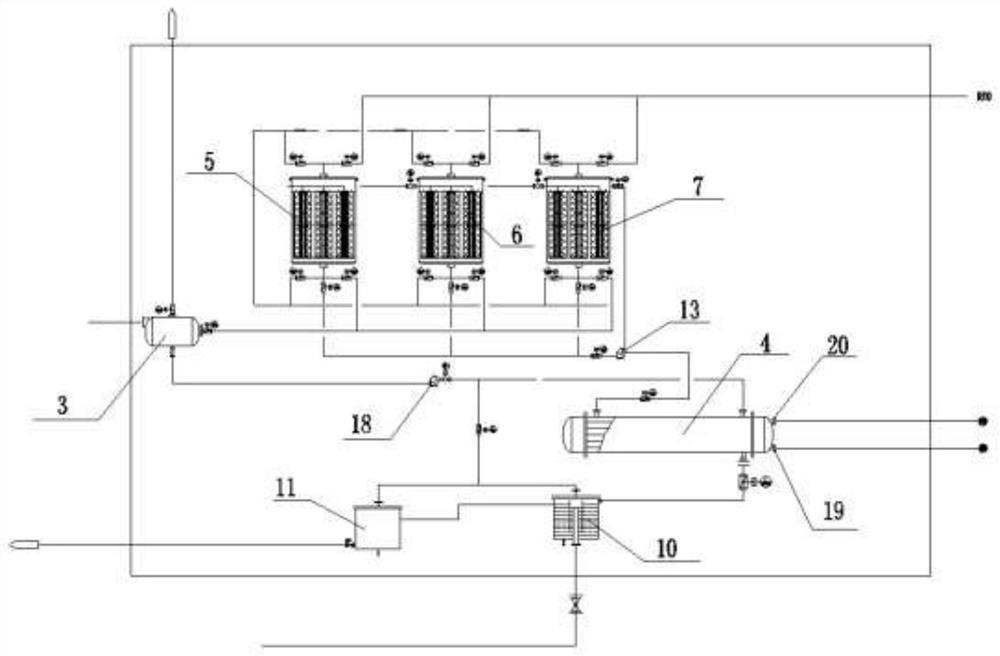

[0044] refer to Figure 1~4 , a dichloromethane waste gas treatment equipment, the equipment includes a spray part and an adsorption part, the spray part includes a first spray tower 1 and a second spray tower 2 connected in sequence, and the adsorption part includes The buffer tank 3, the adsorption tower, the condenser 4, the layered tank 10 and the recovery storage tank 11 are connected in sequence.

[0045] Described adsorption tower comprises the first adsorption tower 5, the second adsorption tower 6 and the standby third adsorption tower 7 connected in series, respectively fill in the first adsorption tower 5, the second adsorption tower 6, the third adsorption tower 7 There is a corresponding hydrophobic macroporous resin 12, and the first adsorption tower 5, the second adsorption tower 6, and the third adsorption tower 7 are respectively connected with the desorption centrifugal pump 13; the first spray tower 1 is connected to the waste gas inlet The pipe 14 communic...

Embodiment 2

[0050] Preparation of Hydrophobic Macroporous Resin

[0051](a) polymerizing monomer (polystyrene, divinylbenzene), porogen (xylene, 200 # Gasoline) mixing, then drop into azobisisobutyronitrile and stir to make it fully dissolve and mix uniformly to obtain an oil phase;

[0052] (b) add deionized water, polyvinyl alcohol and sodium chloride in the reaction vessel and mix, stir and heat up to make the three dissolve completely and mix uniformly to obtain the water phase; wherein, the volume of the deionized water is 4% of the volume of the oil phase times, the volume of polyvinyl alcohol is 0.02 times the volume of deionized water, and the mass fraction of sodium chloride accounts for 3% of the water mass;

[0053] (c) Mix the oil phase with the water phase, set the stirring speed at 500 rpm, and disperse the oil phase into liquid beads; then raise the temperature of the entire mixing system to 60°C, and heat up to 70°C after the liquid beads are shaped, and keep the temperat...

Embodiment 3

[0061] Preparation of Hydrophobic Macroporous Resin

[0062] (a) polymerizing monomer (polystyrene, divinylbenzene), porogen (xylene, 200 # Gasoline) mixing, then drop into azobisisobutyronitrile and stir to make it fully dissolve and mix uniformly to obtain an oil phase;

[0063] (b) add deionized water, polyvinyl alcohol and sodium chloride in the reaction vessel and mix, stir and heat up to make the three dissolve completely and mix uniformly to obtain the water phase; wherein, the volume of the deionized water is 4% of the volume of the oil phase times, the volume of polyvinyl alcohol is 0.02 times the volume of deionized water, and the mass fraction of sodium chloride accounts for 3% of the water mass;

[0064] (c) Mix the oil phase with the water phase, set the stirring speed to 600 rpm, and disperse the oil phase into liquid beads; then raise the temperature of the entire mixing system to 65°C, and heat up to 75°C after the liquid beads are shaped, and keep the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com