High-speed mini photoelectric conversion module design and process method

A technology of photoelectric conversion module and process method, applied in the direction of light guide, optics, optical components, etc., can solve the problems of high manufacturing process difficulty, low yield, supply chain limitation, etc., to reduce the plate making process difficulty, low cost, and improve the The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The processing method of the present embodiment comprises the following steps:

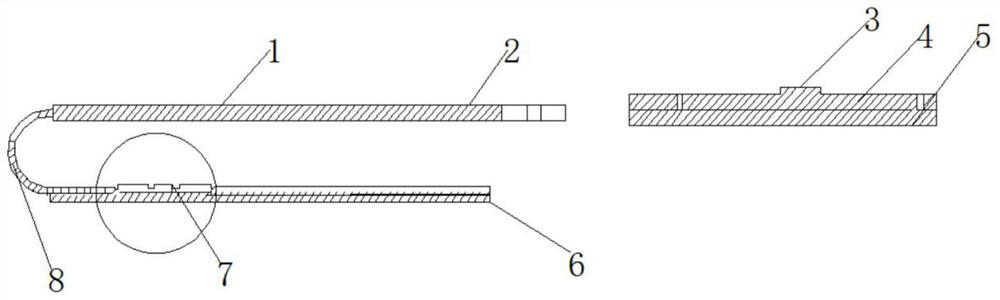

[0024] S1. First, the PCB part adopts an integrated design scheme of 8-layer hard board plus 4-layer soft board plus 6-layer hard board. By reducing the number of soft board layers, the thickness of the soft board is successfully controlled within 0.35mm, which reduces the difficulty of PCB plate making process , Improve the yield of PCB plate making, increase the reliability of the long-term bending of the flexible board, replace the metal wall patch with the design of tungsten copper heat sink and ceramic gasket, the process is simple, and the cost is low.

[0025] S2. Then, at the transmitting end, 12 differential electrical signals are input to the 12-channel VCSEL driver through the 12-channel data port of the optical module, and the 12-channel VCSEL driver simultaneously modulates and drives the 12-channel VCSEL to emit light, and the 12-channel lens array couples the 12-channel optica...

Embodiment 2

[0032] The difference from Embodiment 1 is that:

[0033] The processing method of the present embodiment comprises the following steps:

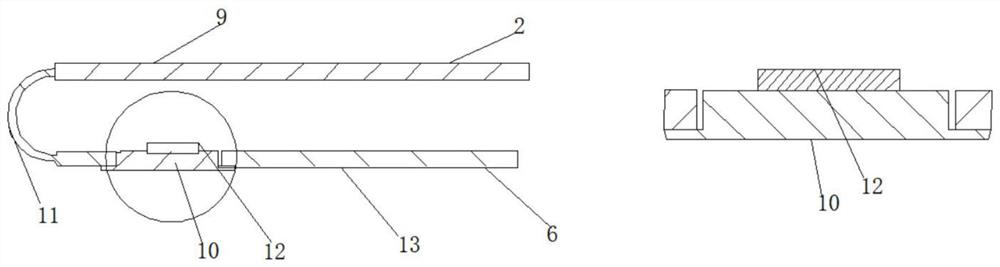

[0034] S1. First, the PCB part is designed with 10-layer hard board and 6-layer soft board. The thickness of the 6-layer soft board is controlled at 0.4mm. The manufacturing process is very difficult, and the yield is not high. Paste the metal wall board on the 6-layer soft board. The upper process is complicated and difficult, and the yield rate is not high.

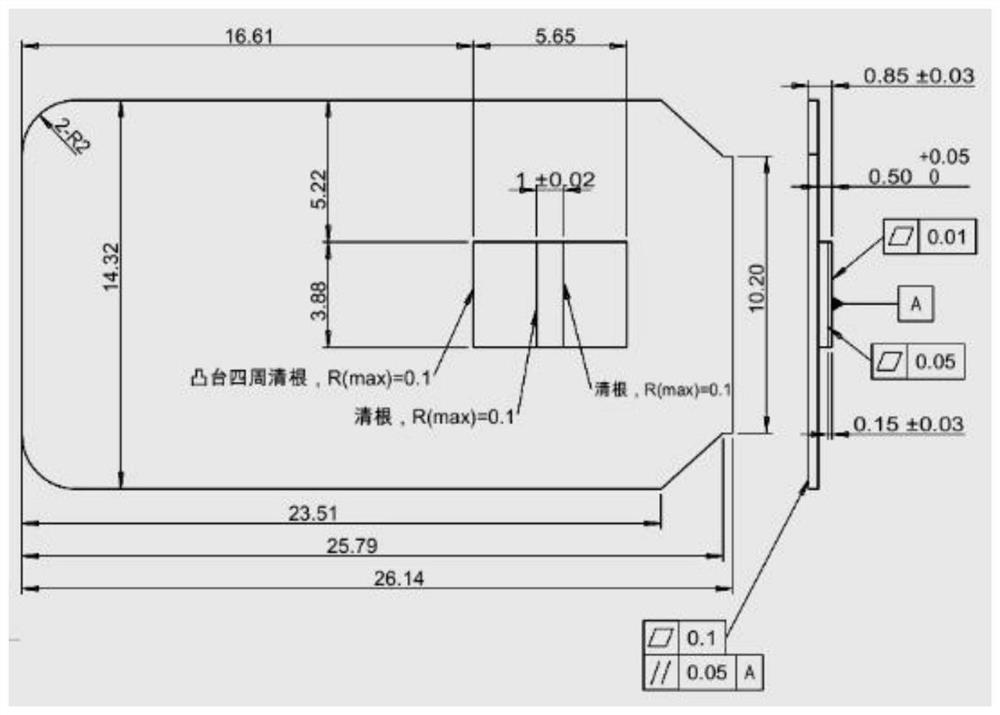

[0035] S2. Then, the design drawing of the metal wall patching board requires that the surface flatness of the metal wall patching board substrate is not less than 0.1mm, the surface flatness of the large boss is not less than 0.05mm, and the surface roughness of the small boss is not less than 0.01mm. The joints of the platform and the small boss are cleaned around, and the chamfer is less than 0.1mm. The manufacturing process is difficult and exceeds the general machining accuracy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com