Doped copper silicate nanotube catalyst for methyl acetate hydrogenation as well as preparation method and application of doped copper silicate nanotube catalyst

A technology of methyl acetate and catalyst, which is applied in the field of doped copper silicate nanotube catalyst and its preparation, can solve the problems of low conversion rate of ethylene per pass, push up the price of grain, and high product cost, so as to reduce equipment investment cost, Strong tolerance, the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. a doped copper silicate nanotube catalyst of methyl acetate hydrogenation, comprising carrier, main catalyst and cocatalyst, described carrier is silicon dioxide, and main catalyst is the oxide compound of Cu, and cocatalyst is rare earth element Oxides of Ce; the main catalyst accounts for 30% of the mass of the carrier, and the cocatalyst accounts for 5% of the mass of the carrier.

[0039] 2. the preparation method of described catalyst, comprises the following steps:

[0040] (1) Add 4.95g of copper nitrate trihydrate and 4.58g of ammonium chloride into 120mL of water to form an aqueous solution, add 28wt% ammonia water dropwise to the pH of the solution to 9.5, stir at room temperature for 0.5h, and form a blue suspension;

[0041] (2) Slowly add 1.728 g of silica sol dropwise to the blue suspension, and stir at room temperature for 1 hour to form a blue colloidal solution;

[0042] (3) Hydrothermal crystallization at 200°C for 40 hours;

[0043] (4) After coo...

Embodiment 2

[0048] 1. a doped copper silicate nanotube catalyst of methyl acetate hydrogenation, comprising carrier, main catalyst and cocatalyst, described carrier is silicon dioxide, and main catalyst is the oxide compound of Cu, and cocatalyst is rare earth element Oxides of La; the main catalyst accounts for 30% of the mass of the carrier, and the cocatalyst accounts for 3% of the mass of the carrier.

[0049] 2. the preparation method of described catalyst, comprises the following steps:

[0050] (1) Add 4.95g of copper nitrate trihydrate and 4.58g of ammonium chloride into 120mL of water to form an aqueous solution, add 28 wt% ammonia water dropwise to the pH of the solution to 9.5, stir at room temperature for 0.5h, and form a blue suspension ;

[0051] (2) Slowly add 1.728 g of silica sol dropwise to the blue suspension, and stir at room temperature for 1 hour to form a blue colloidal solution;

[0052] (3) Hydrothermal crystallization at 200°C for 40 hours;

[0053] (4) After ...

Embodiment 3

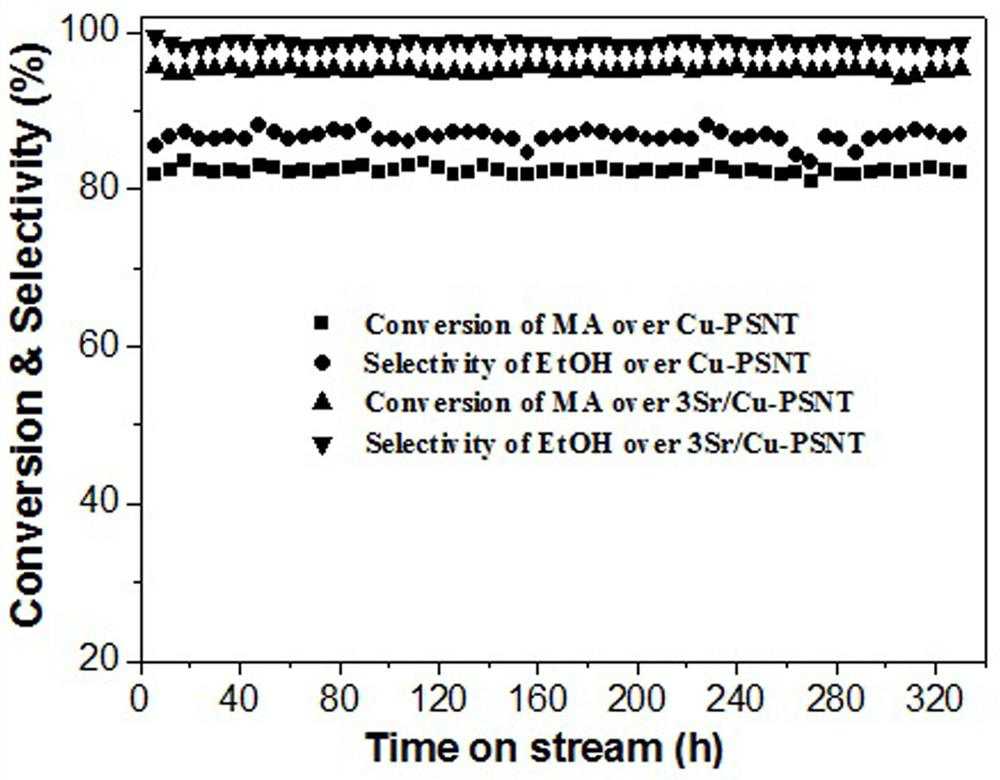

[0058] 1. a doped copper silicate nanotube catalyst of methyl acetate hydrogenation, comprising carrier, main catalyst and cocatalyst, described carrier is silicon dioxide, and main catalyst is the oxide compound of Cu, and cocatalyst is alkaline earth metal Oxides of Sr; the main catalyst accounts for 35% of the mass of the carrier, and the cocatalyst accounts for 5% of the mass of the carrier.

[0059] 2. the preparation method of described catalyst, comprises the following steps:

[0060] (1) Add 5.78g of copper nitrate trihydrate and 5.34g of ammonium chloride into 120mL of water to form an aqueous solution, add 28 wt% ammonia water dropwise to the pH of the solution to 9.5, stir at room temperature for 0.5h, and form a blue suspension ;

[0061] (2) Slowly add 1.728 g of silica sol dropwise to the blue suspension, and stir at room temperature for 1 hour to form a blue colloidal solution;

[0062] (3) Hydrothermal crystallization at 200°C for 40 hours;

[0063] (4) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com