Oil-absorbing white radish-based carbon aerogel and preparation method thereof

A technology of carbon airgel and white radish, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of harsh preparation conditions, complicated methods, and high equipment requirements for bacterial cellulose, and achieve high practical value and Application prospect, simplification of preparation process, and avoidance of high-temperature calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

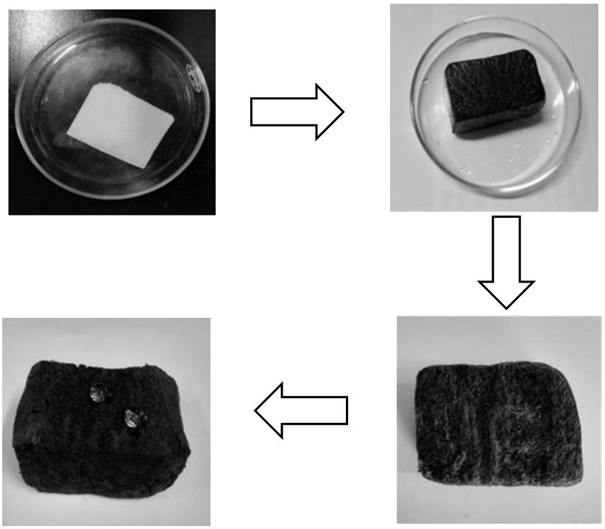

Embodiment 1

[0039] After peeling the white radish, cut it into regular white radish rectangular cubes, place it in the polytetrafluoroethylene lining in the stainless steel autoclave, and the solvent is deionized water. The reaction kettle was placed in an oven at 180° C., hydrothermally reacted for 10 h, and then cooled to room temperature naturally. The product was washed twice with deionized water and ethanol at 70°C, and then soaked in deionized water for 24 hours to remove soluble impurities to obtain a black carbonaceous hydrogel. The carbonaceous hydrogel was pre-frozen in the refrigerator for 12 hours, and then vacuum-dried in a vacuum freeze dryer at -65°C for 48 hours to finally prepare the white radish-based carbon aerogel.

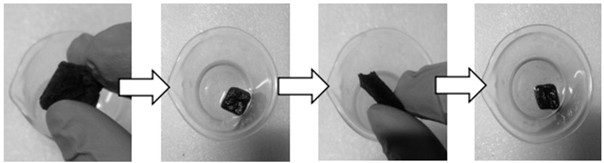

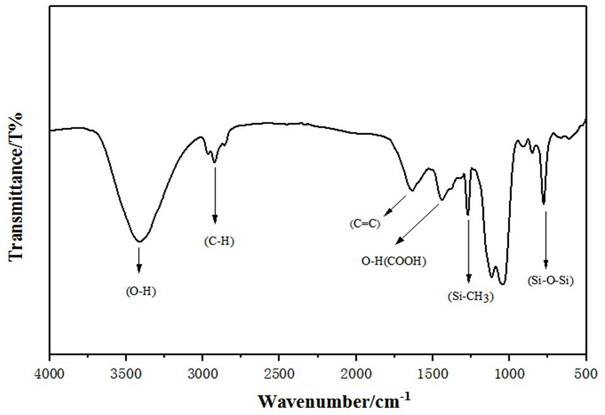

[0040] The carbon aerogel was modified by simple chemical vapor deposition, and the carbon aerogel was placed in a closed container together with two beakers filled with deionized water and methyltrimethoxysilane respectively (deionized water and methyltri...

Embodiment 2

[0043] After peeling the white radish, cut it into regular cuboid radish pieces, place them in the polytetrafluoroethylene lining in the stainless steel autoclave, and the solvent is deionized water. The reaction kettle was placed in an oven at 180°C, hydrothermally reacted for 10 h, and then cooled to room temperature naturally. The product was washed with 70°C deionized water and ethanol four times respectively, and then soaked in deionized water for 24 hours to remove soluble impurities to obtain a black carbonaceous hydrogel. The carbonaceous hydrogel was pre-frozen in the refrigerator for 12 hours, and then vacuum-dried in a vacuum freeze dryer at -65°C for 48 hours to finally prepare the white radish-based carbon aerogel.

[0044] The carbon airgel was modified by simple chemical vapor deposition, and the carbon airgel was placed in a closed container together with two beakers filled with ammonia water and methyltrimethoxysilane (ammonia water and methyltrimethoxysilane ...

Embodiment 3

[0047] After peeling the white radish, cut it into regular cuboid white radish pieces, place them in the polytetrafluoroethylene lining in the stainless steel autoclave, and the solvent is deionized water. The reaction kettle was placed in an oven at 180°C, hydrothermally reacted for 10 h, and then cooled to room temperature naturally. The product was washed with 70°C deionized water and ethanol four times respectively, and then soaked in deionized water for 24 hours to remove soluble impurities to obtain a black carbonaceous hydrogel. The carbonaceous hydrogel was pre-frozen in the refrigerator for 12 hours, and then the carbonaceous wet gel was placed in a vacuum freeze dryer at -65°C for 48 hours in vacuum to finally prepare the white radish-based carbon aerogel.

[0048] The carbonaceous aerogel was modified by simple chemical vapor deposition, and the carbon aerogel was placed in a closed container together with two beakers filled with deionized water and dimethyldiethoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption rate | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com