Preparation method and device of organic functional group modified nano zero-valent iron repairing agent

A technology of organic functional groups and nano-zero-valent iron, which is applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of low repair efficiency and rebound of repair effect, and achieve low repair cost, high repair efficiency, and reduced Effects on Mobility and Bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

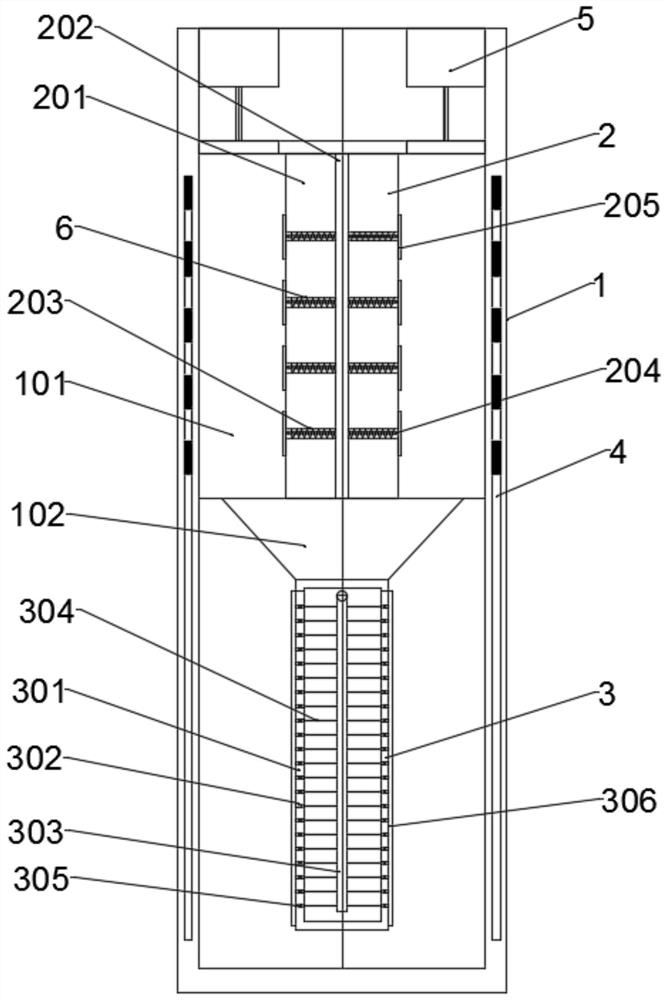

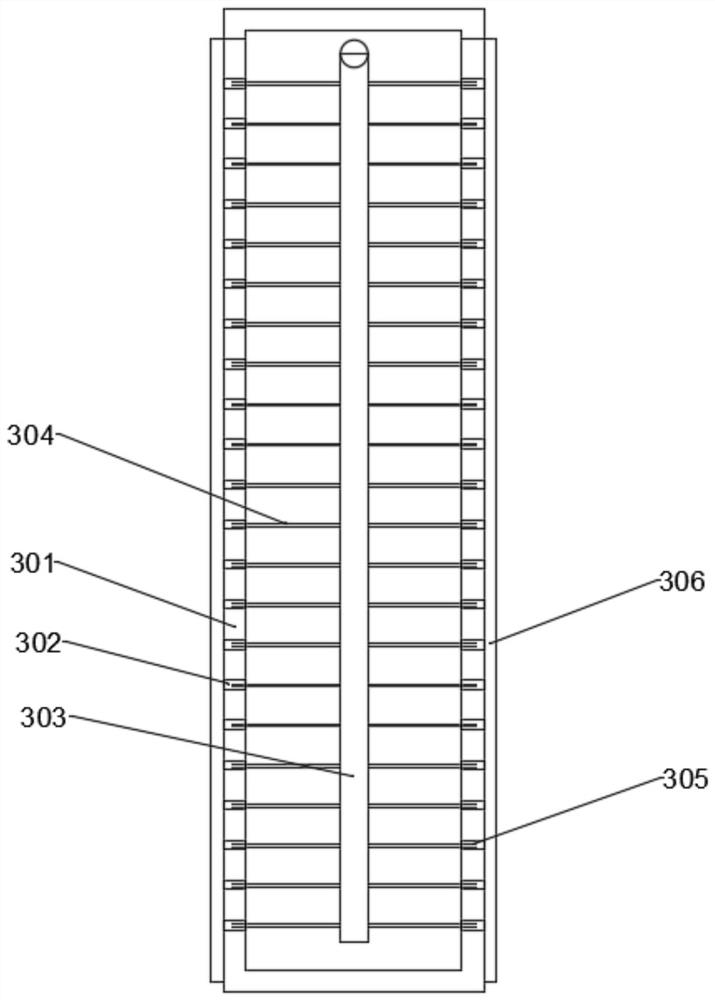

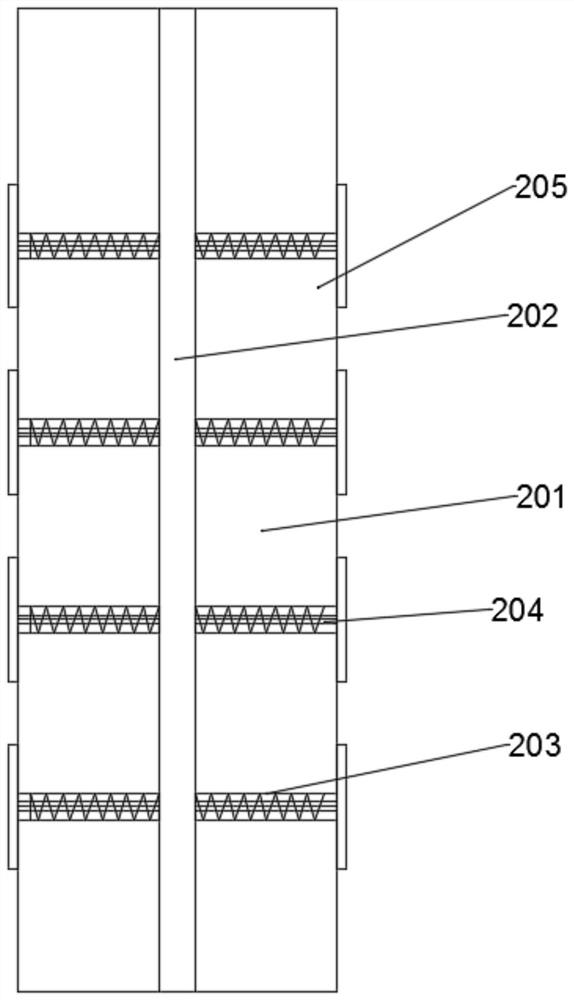

[0048] Such as Figure 4 As shown, the present invention provides a method for preparing an organic functional group modified nanometer zero-valent iron restoration agent, comprising specific steps:

[0049] S100. Hydrolyzing the biological by-products by high-temperature cooking to obtain a preliminary hydrolyzate; subjecting the preliminary hydrolyzate to high-temperature puffing and cracking, followed by dehydration, drying and pulverization, and finally obtaining a modified biological preparation of amino acid active groups;

[0050] S200, configuring the modified biological preparation of the amino acid active group into a solution, adding an iron salt solution to the solution for mixing and modification, and fully stirring and mixing to form a chelate mixture;

[0051] S300. Add borohydride salt solution dropwise to the chelate mixture, and obtain a black suspension of nanometer zero-valent iron through liquid phase reduction reaction, and perform suction filtration and ...

specific Embodiment

[0093] Specific embodiment one of the present invention for repairing soil of unmodified repairing agent and modifying agent through amino acid modification (governance of hexavalent chromium pollution in soil):

[0094] Test site: a chromium slag landfill in Shandong; Pollution type: Soil Cr(VI) pollution; Pollution degree: Cr(VI) pollution concentration is about 1×104mg / kg; Pollution source: Chromium slag is randomly piled up, rain leaching into the soil ; Restoration method: use iron-copper bimetallic nanoparticles (Fe / Cu), modified iron-copper bimetallic nanoparticles (AA-Fe / Cu) and pre-adjust the pH to 3, and the initial pollution concentration of Cr(VI) is 9610mg / kg of soil was mixed evenly at a ratio of 1:10, and repaired at a constant temperature of 25°C.

[0095] After standing still and waiting for the repair effect, samples were taken to detect the residual concentration of Cr(VI) in the soil, and the removal rate of Cr(VI) in the soil was calculated by different m...

specific Embodiment 2

[0099] Specific embodiment two of the present invention (control of hexavalent chromium pollution in water):

[0100] Test sample: chromium-contaminated water sample; sample source: Yuxing chromium slag landfill; pollution degree: Cr(VI) concentration 1370mg / kg; repair method: amino acid biological agent (nano zero-valent iron modifier) and chromium-contaminated water Samples were mixed at a mass ratio of 1:15, and repaired at room temperature.

[0101] After standing still and waiting for the restoration to be completed, filter the supernatant to detect the residual concentration of Cr(VI) in the water sample, and analyze the chelation effect of amino acid biological preparations (nano-zero-valent iron modifier) on hexavalent chromium.

[0102] The test results showed that Cr(VI) was not detected in the water samples, and the preliminary results showed that amino acid biological preparations have a strong chelation effect on Cr(VI), and can form stable macromolecules with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com