A preparation method of superhydrophobic self-cleaning wood

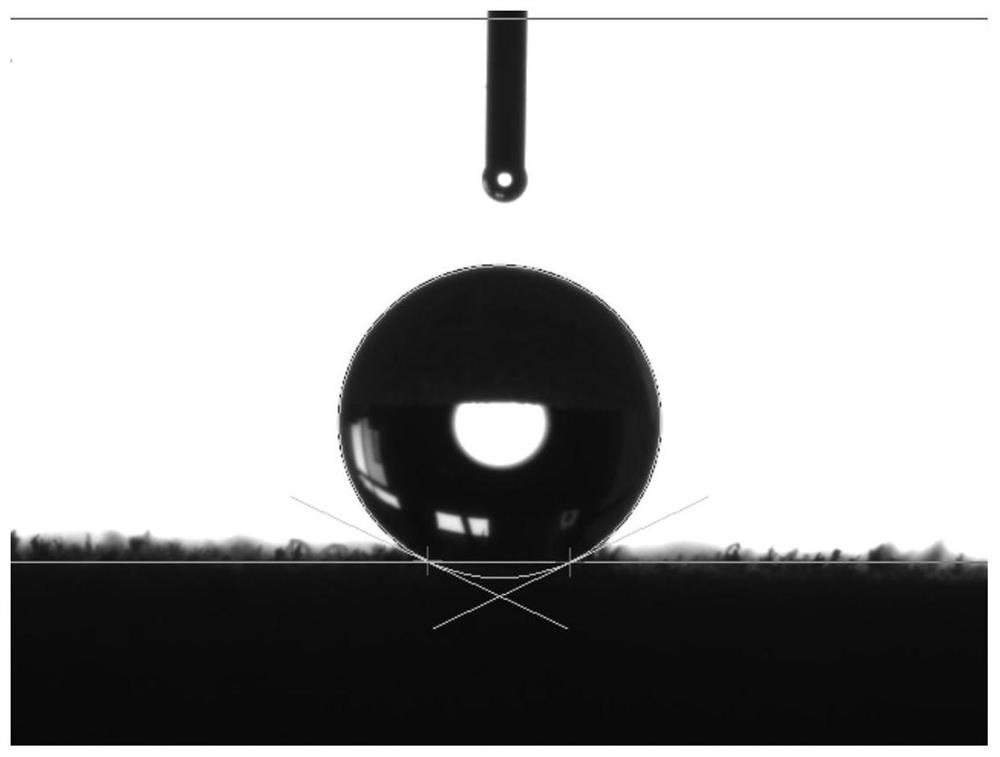

A self-cleaning, super-hydrophobic technology, applied in wood treatment, wood impregnation, impregnated wood, etc., can solve the problems of poor bonding strength between resin coating and wood, poor mechanical properties, lack of self-cleaning function, etc., and achieve dimensional stability Good, strong anti-corrosion performance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

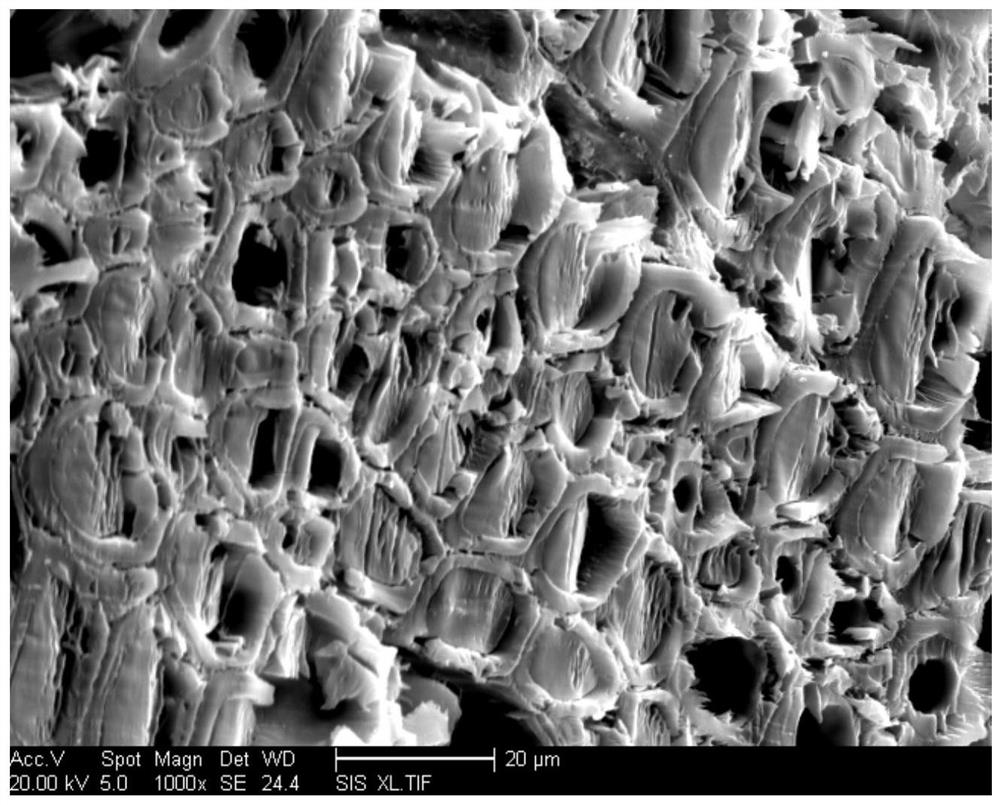

[0034] Specific embodiment one: the preparation method of superhydrophobic self-cleaning characteristic wood of this embodiment comprises the following steps:

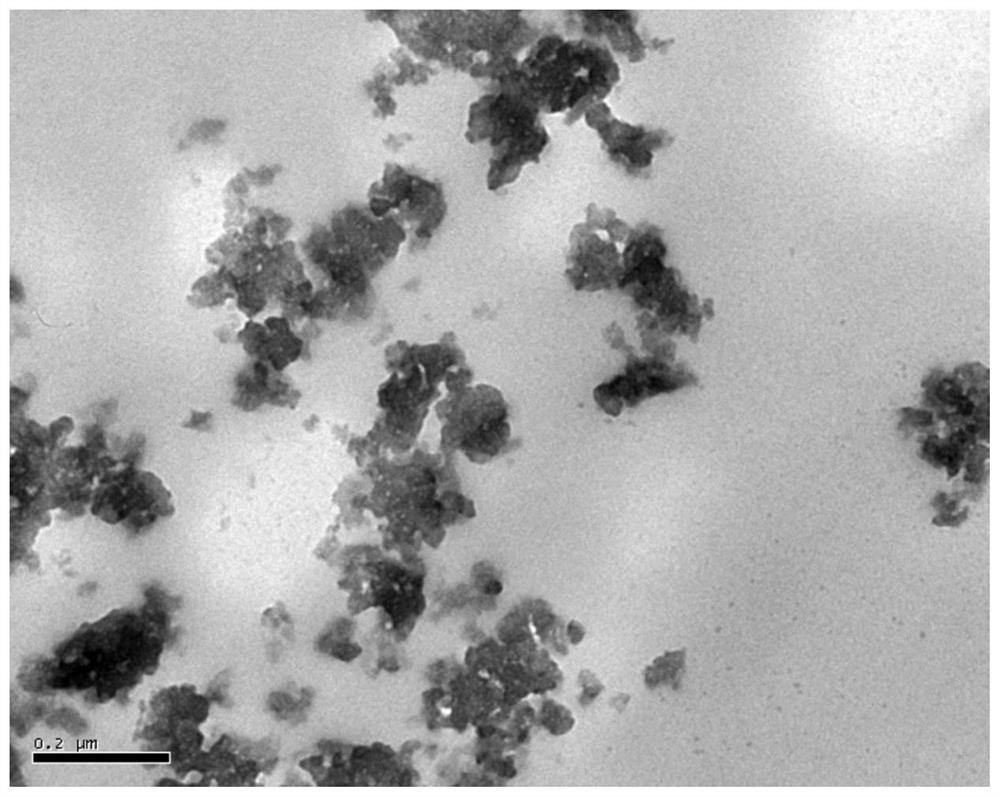

[0035] Step 1: Weigh 49-99 parts of fluorine-containing polymerizable monomers, 0-30 parts of unsaturated monomers, 0.5-10 parts of POSS nanoparticles, and 0.1-10 parts of amino-modified MXene and 0.4 to 1 part of initiator, first mix POSS nanoparticles and amino-modified MXene into tetrahydrofuran, stir to dissolve, then add fluorine-containing polymerizable monomer, unsaturated monomer and initiator, and mix evenly to obtain Impregnation solution; wherein the mass ratio of tetrahydrofuran to fluorine-containing polymerizable monomer is 1:1;

[0036] Step 2: Add wood and impregnating solution into the reaction tank, and immerse the wood in the impregnating solution. After sealing the reaction tank, feed nitrogen gas to make the pressure in the reaction tank reach 0.8MPa~1MPa, and keep it for 20min~30min ;

[0037] S...

specific Embodiment approach 2

[0043] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the fluorine-containing polymerizable monomer described in step 1 is hexafluorobutyl acrylate, hexafluorobutyl methacrylate, trifluorooctyl acrylate, Trifluorooctyl methacrylate or dodecafluoroheptyl methacrylate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the unsaturated monomer described in step one is acrylic acid, methacrylic acid, alkyl acrylate, alkyl methacrylate, glycidyl acrylate , glycidyl methacrylate, allyl glycidyl ether, α-hydroxyalkyl acrylate, α-hydroxyalkyl methacrylate, aminoalkyl acrylate, aminoalkyl methacrylate, multiple Alcohol diacrylate, polyol dimethacrylate or a combination of several of them. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com