A reducing ion-exchange membrane for treating sewage containing precious metals and recovering high-purity precious metals, and its preparation and application

An ion exchange membrane and ion exchange technology, applied in the field of reductive ion exchange, can solve the problems of low current density of electrochemical diffusion, inability to directly recover precious metals, membrane fouling cycle stability, etc., and achieve high metal removal/recovery efficiency. , good removal/recovery capacity, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The second aspect of the present invention provides a method for preparing a reducing ion-exchange membrane for treating precious metal sewage and recovering high-purity precious metal simple substances, including:

[0054] Take Na 2 WO 4 2H 2 O as tungsten source, WO prepared by hydrothermal method 3 powder;

[0055] The above WO 3 The powder is evenly mixed with the conductive agent and the binder, brushed on the current collector and dried to obtain a reducing ion exchange membrane.

[0056] The preparation method of the invention is simple, the raw material cost is low, the operation is convenient and the practicability is strong.

[0057] The third aspect of the present invention provides a reductive ion exchange method for treating precious metal sewage and recovering high-purity precious metal simple substances, including:

[0058] Take any of the above-mentioned ion exchange membranes as the working electrode, first place the reducing ion exchange membrane...

Embodiment 1

[0083] A reductive ion exchange technology for treating precious / heavy metal wastewater and recovering high-purity metal elements, comprising the following steps:

[0084] (1) Preparation of reducing ion exchange membrane

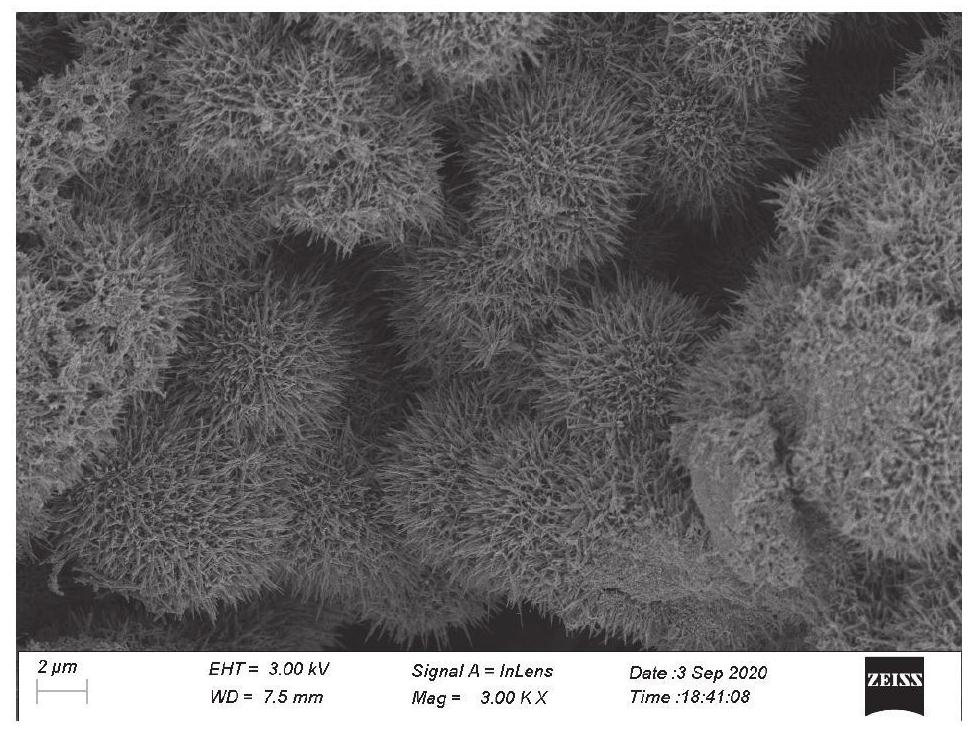

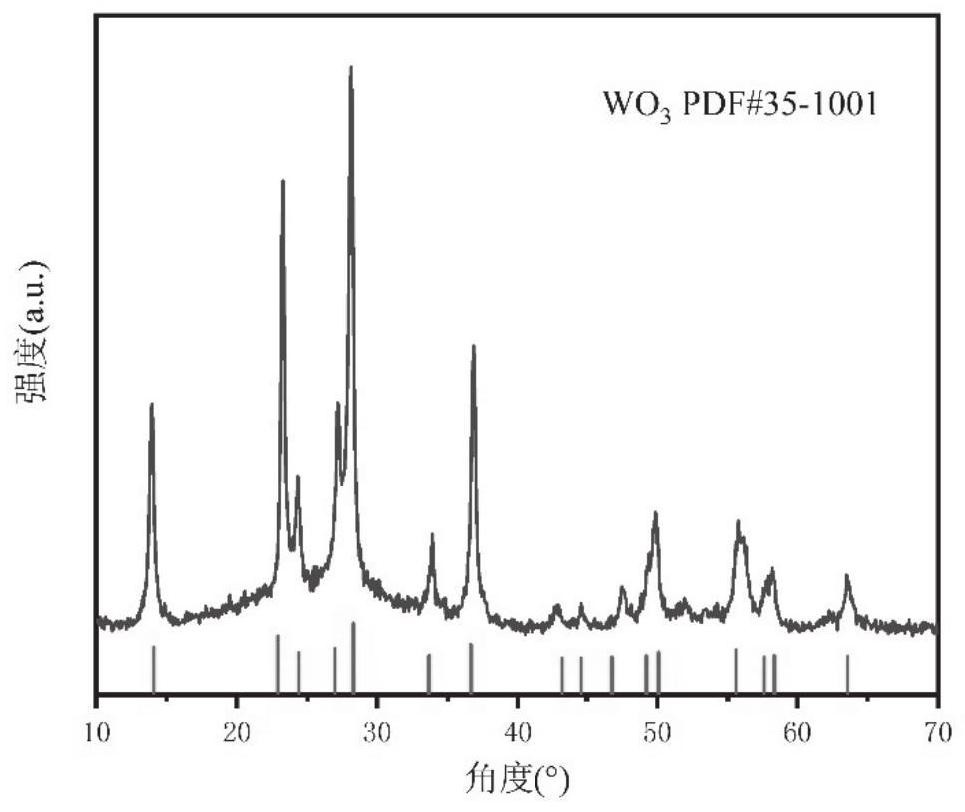

[0085] a. WO 3 Preparation of Nanomaterials

[0086] 4.5gNa 2 WO 4 2H 2 O was added to 100mL of deionized water, fully stirred and dissolved; 3M HCl solution was added dropwise to adjust the pH to 1.2; 3.78g oxalic acid was added and fully stirred; 12.5g (NH 4 ) 2 SO 4 As a structure directing agent, stir well to a clear and transparent solution. The obtained solution was placed in a 50mL reactor, and the WO 3 powder, the powder is placed in a muffle furnace for calcination, the calcination temperature is 300°C, and the calcination time is 2h.

[0087] b. Preparation of reducing ion exchange membrane

[0088] 80wt% active substance WO 3 , 10wt% Ketjen Black, 10wt% polyvinylidene fluoride binder, fully grind and mix, add a small amount of N-methylpy...

Embodiment 2

[0100] Step is with embodiment 1, wherein the AgNO in step (3) and (4) 3 The solution was changed to KAuCl 4 solution.

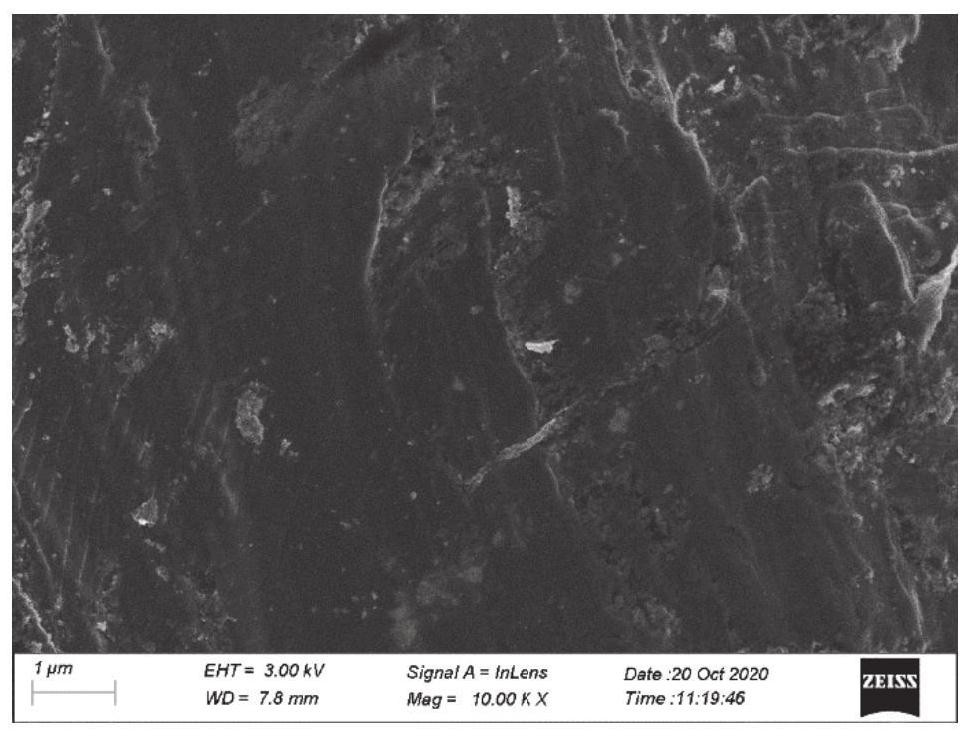

[0101] Figure 8 is the reducing ion exchange membrane in KAuCl 4 The SEM photograph of the surface after the solution reduced Au, it can be observed that there is reduced granular Au element on the surface of the exchange membrane.

[0102] Figure 9 is the reducing ion exchange membrane in KAuCl 4 XRD patterns after solution circulation immersion. The diffraction peaks in this figure are sharp and consistent with the standard card comparison of elemental Au, indicating that Au is reduced on the surface of the film.

[0103] Figure 10 Yes is the reducing ion exchange membrane in KAuCl 4 Elemental distribution pictures after solution circulation immersion. According to the element distribution map, the granular Au has obvious edges and has a large contrast with the film background.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com