Zirconia ceramics and its preparation method and application

A technology of zirconia ceramics and zirconia, applied in the field of zirconia ceramics and its preparation, can solve the problems of increased processing difficulty, high density, high cost, etc., and achieve the effect of low dielectric constant and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

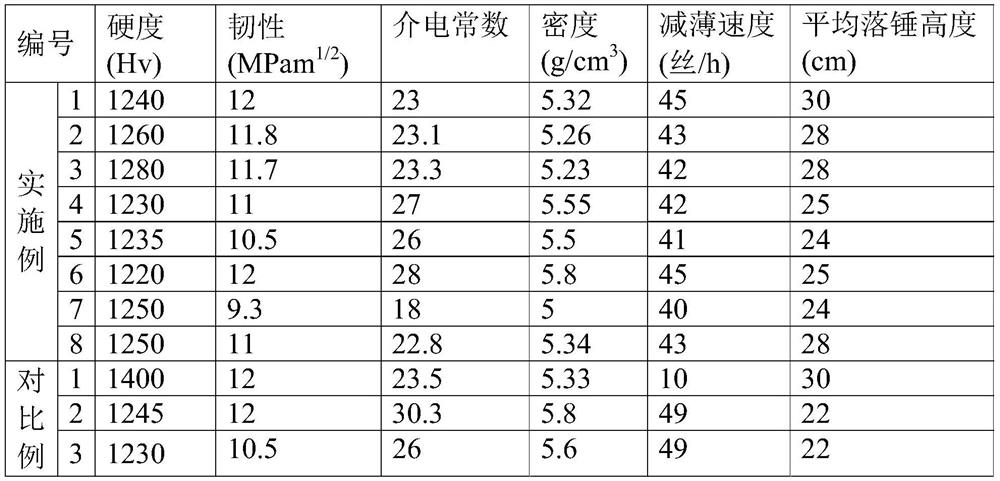

Examples

preparation example Construction

[0027] The second aspect of the present invention provides a method for preparing zirconia ceramics, including: (1) adding niobium oxide and / or tantalum oxide, and zirconium oxide, yttrium oxide, zinc aluminate and / or magnesium aluminate, zirconium silicate The powder is wet-milled with water, dispersant and binder to obtain a slurry; (2) drying the slurry to obtain a composite zirconia powder; (3) molding the composite zirconia powder , and then sintered in air to obtain ceramics.

[0028] In the present invention, the powders of niobium oxide, tantalum oxide, zirconium oxide, yttrium oxide, zinc aluminate and / or magnesium aluminate, and zirconium silicate can be provided alone or in combination in the form of high-purity powder. For example, yttria and zirconia can be stabilized by tetragonal zirconia powder containing 2-4mol% yttrium oxide (median particle size 0.3-0.6μm, specific surface area 7-13m 2 / g), wherein the content of yttrium oxide is based on zirconia. Niobium...

Embodiment 1

[0054] Raw materials: 200g of composite powder, which contains niobium pentoxide (Nb 2 o 5 ) 2.5wt%, zinc aluminate (ZnAl 2 o 4 ) 12.3wt%, zirconium silicate 22.3wt%, 62.9wt% zirconia powder containing 3mol% yttria stabilized.

[0055] The raw material is added water ball milling 8h in the ball mill tank, then in the sand mill, add 0.02wt% hypromellose and water sand milling 10h, finally add the binding agent of 4wt% powder (molar ratio is 1: 1 PEG4000 and PVA) were stirred for 0.5h to form a spray slurry with a solid content of 25% by weight;

[0056] The slurry is sent to the spray tower for spray drying (inlet air temperature is 250°C, outlet air temperature is 110°C, centrifugal speed is 15 rpm) to form a spherical powder with strong fluidity for dry pressing, and then dry pressing (A press with a tonnage of 200 tons uses an oil pressure of 8MPa);

[0057] The molded powder is heated from room temperature to 600°C for 400 minutes and kept for 2 hours, raised from 600°...

Embodiment 2

[0062] Raw materials: 200g of composite powder, which contains niobium pentoxide (Nb 2 o 5 ) 2.5wt%, magnesium aluminate (MgAl 2 o 4 ) 12.3wt%, zirconium silicate 22.3wt%, 62.9wt% yttria-stabilized zirconia powder containing 3mol%.

[0063]Add water ball mill to raw material in ball mill tank for 8h, then add 0.01wt% triethanolamine and water sand mill in sand mill for 10h, finally add 5wt% binder of powder (mole ratio is PEG4000 of 1:1 and PVA) to stir for 0.5h to form a spray slurry with a solid content of 55% by weight;

[0064] The slurry is sent to the spray tower for spray drying (inlet air temperature is 250°C, outlet air temperature is 110°C, centrifugal speed is 15 rpm) to form a spherical powder with strong fluidity for dry pressing, and then dry pressing (A press with a tonnage of 200 tons uses an oil pressure of 8MPa);

[0065] The molded powder is heated from room temperature to 600°C for 400 minutes and kept for 2 hours, raised from 600°C for 300 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com