Carbon-nitrogen material loaded nickel catalyst with adjustable mesoporous aperture as well as preparation method and application of carbon-nitrogen material loaded nickel catalyst

A carbon-nitrogen material and nickel-loaded technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc., can solve problems such as low catalytic efficiency, low catalyst service life, and poor mass transfer effect. Achieve the effects of high cycle stability, high specific surface area, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

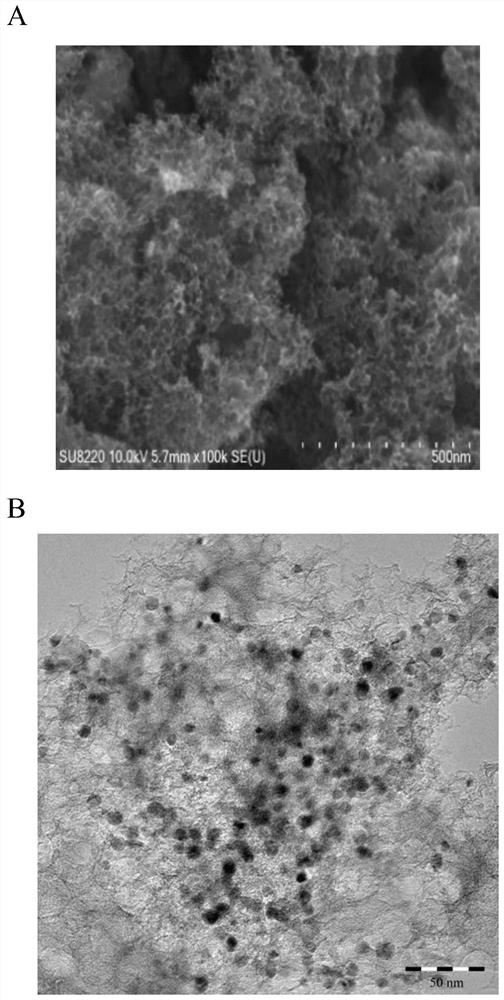

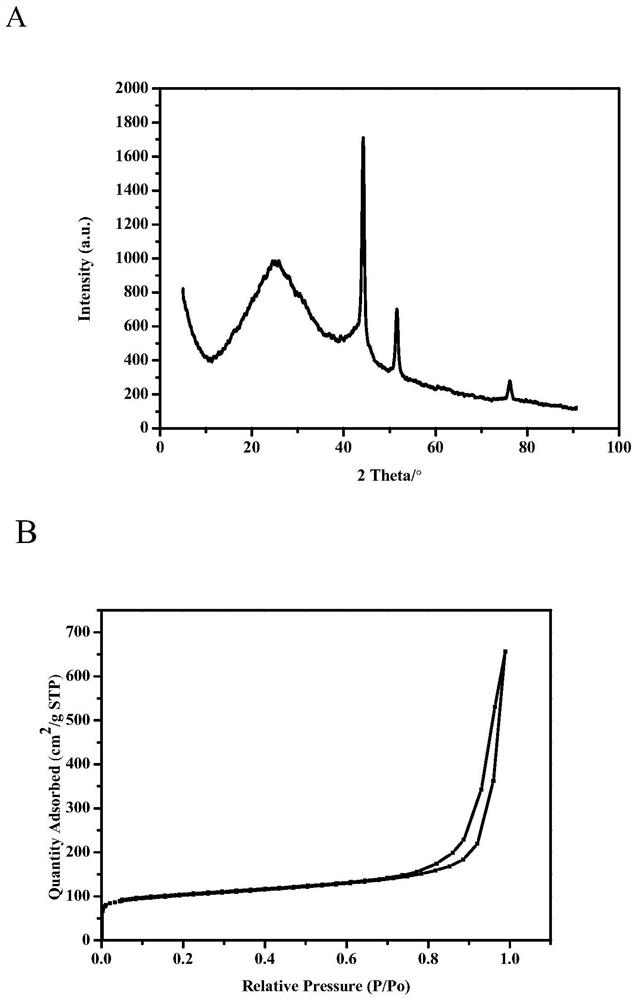

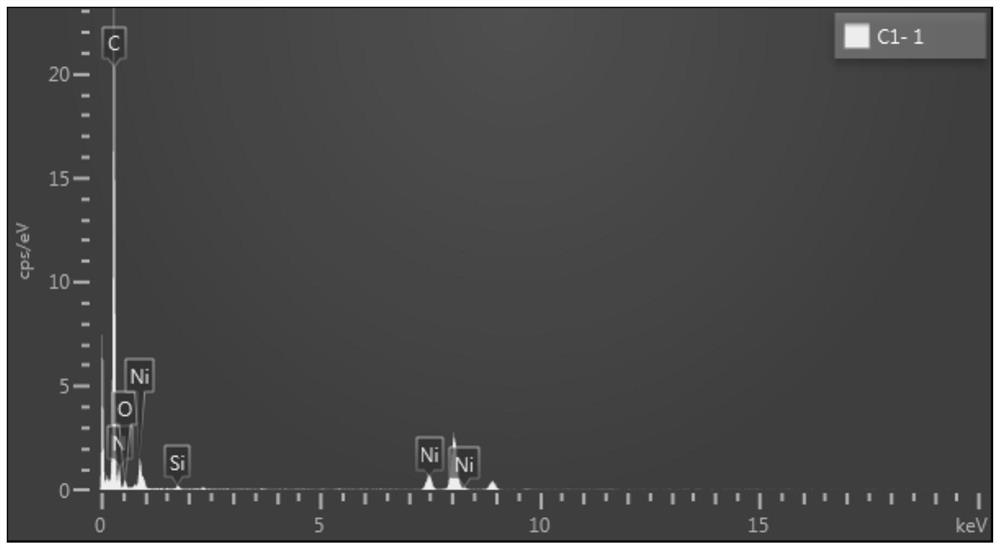

[0046] 1) In a 100ml beaker, weigh 4g of LUDOX@AS-40, add 4g of glucosamine hydrochloride into 50ml of distilled water, and stir for 2 hours at a speed of 300rpm-500rpm to form a uniform transparent mixture.

[0047] 2) Transfer the mixture into a hydrothermal reaction kettle, raise the temperature to 160° C. at a rate of 10° C. / min and react for 12 hours to obtain a black-brown mixture.

[0048] 3) Put the black-brown mixture in an oven at 50°C and dry for 24 hours to obtain a composite of carbon-nitrogen precursor and template agent.

[0049] 4) transfer the obtained compound into the tube furnace, under N 2 Under an atmosphere of 5°C / min, the temperature was raised to 800°C for 2h at a constant temperature to obtain a black solid.

[0050] 5) Add the obtained black solid powder to a 200ml beaker, add 150ml deionized water and 10g sodium hydroxide, wash until neutral, put the obtained filter residue in an oven at 50°C and dry for 24h to obtain a nitrogen-doped carbon carrie...

Embodiment 2

[0059] 1) In a 100ml beaker, weigh 4g of LUDOX@HS-40, add 4g of glucosamine hydrochloride into 50ml of distilled water, and stir for 2 hours at a speed of 300rpm-500rpm to form a uniform transparent mixture.

[0060] 2) Transfer the mixture into a hydrothermal reaction kettle, raise the temperature to 160° C. at a rate of 10° C. / min and react for 12 hours to obtain a black-brown mixture.

[0061] 3) Put the black-brown mixture in an oven at 50°C and dry for 24 hours to obtain a composite of carbon-nitrogen precursor and template agent.

[0062] 4) transfer the obtained compound into the tube furnace, under N 2 Under an atmosphere of 5°C / min, the temperature was raised to 800°C for 2h at a constant temperature to obtain a black solid.

[0063] 5) Add the obtained black solid powder into a 200ml beaker, add 150ml deionized water and 10g sodium hydroxide, wash until neutral, put the obtained filter residue in an oven at 50°C and dry for 24h to obtain a nitrogen-doped carbon carr...

Embodiment 3

[0070] 1) In a 100ml beaker, weigh 4g of LUDOX@SM, add 4g of glucosamine hydrochloride into 50ml of distilled water, and stir for 2 hours at a speed of 300rpm-500rpm to form a uniform transparent mixture.

[0071] 2) Transfer the mixture into a hydrothermal reaction kettle, raise the temperature to 160° C. at a rate of 10° C. / min and react for 12 hours to obtain a black-brown mixture.

[0072]3) Put the black-brown mixture in an oven at 50°C and dry for 24 hours to obtain a composite of carbon-nitrogen precursor and template agent.

[0073] 4) transfer the obtained compound into the tube furnace, under N 2 Under an atmosphere of 5°C / min, the temperature was raised to 800°C for 2h at a constant temperature to obtain a black solid.

[0074] 5) Add the obtained black solid powder to a 200ml beaker, add 150ml deionized water and 10g sodium hydroxide, wash until neutral, put the obtained filter residue in an oven at 50°C and dry for 24h to obtain a nitrogen-doped carbon carrier, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com