Preparation method of boron carbide nanosheet

A technology of nanosheets and boron carbide, which is applied in the field of preparation of boron carbide nanosheets, can solve the problems of short synthesis process, high purity, and inability to form regularly arranged boron carbide nanosheets, and achieve process controllability, high purity, and shortened gas flow The effect of crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

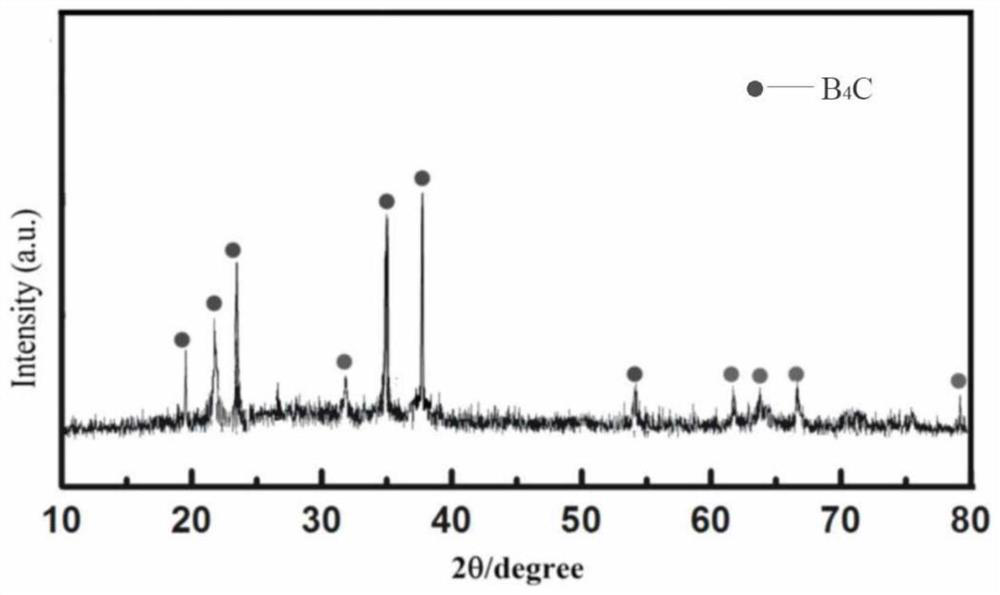

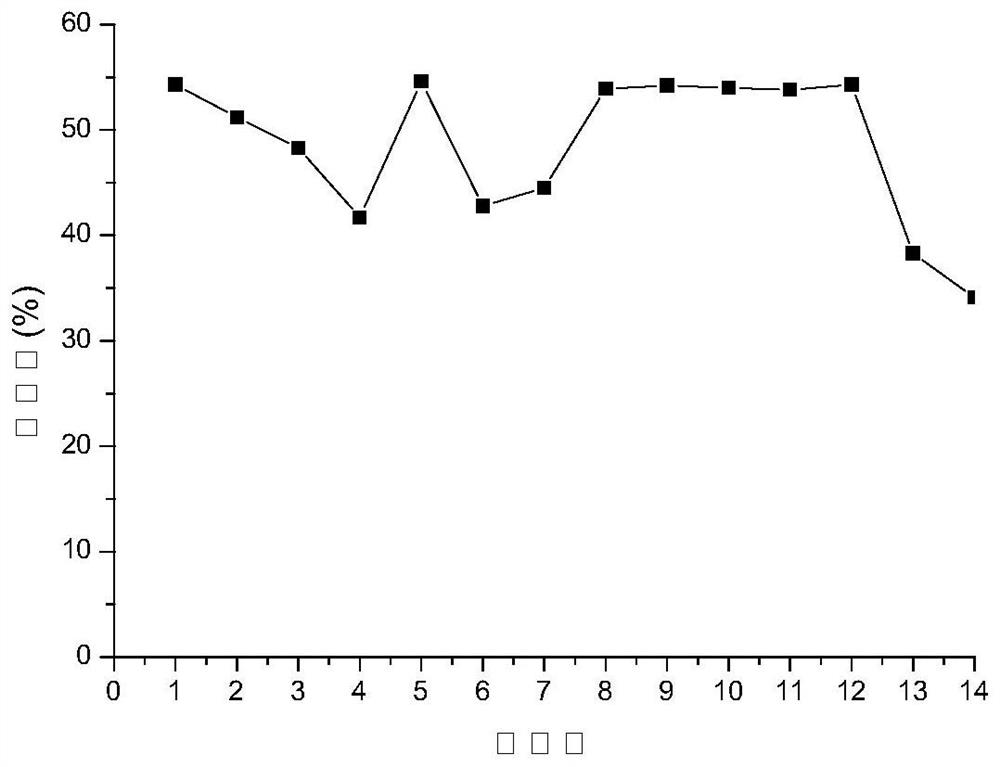

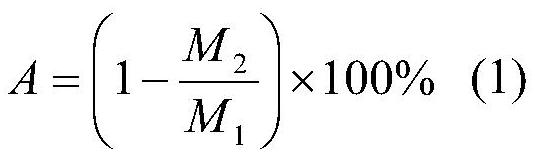

Image

Examples

Embodiment 1

[0036] Embodiment 1: A kind of preparation method of boron carbide nanosheet

[0037] This embodiment provides a method for preparing boron carbide nanosheets, comprising the following steps:

[0038] 1) First mix boric acid and polyvinyl alcohol (polymerization degree: 1700) according to the molar ratio of 5:1, add 2% magnesium oxide and silicon dioxide mixture with a mixing ratio of 7:3, and put the mixture into vacuum freeze-drying Freeze-dry in the machine, control the freeze-dryer at -40°C, vacuum at 20Pa, and freeze-dry for 4 hours;

[0039] 2) Then add the mixed powder to the jet mill at a feeding speed of 110g / min, add a mixture of triethanolamine and coke at a rate of 0.5% by weight of the powder as a grinding aid, and the mixing ratio of triethanolamine and coke is 1:5 , pulverize for 60s, keep the pressure inside the jet mill at 1.5MPa, the temperature at 20°C, and the air velocity at 180m / s; then pulverize the powder for the second time, adding 1.2% of the powder we...

Embodiment 2

[0042] Embodiment 2: Another kind of preparation method of boron carbide nanosheet

[0043] Example 2 is basically the same as Example 1, except that the carbon source in Example 2 is polyethylene with a polymerization degree of 1700.

Embodiment 3

[0044] Embodiment 3: Another kind of preparation method of boron carbide nanosheet

[0045] Example 3 is basically the same as Example 1, except that the carbon source in Example 3 is polypropylene with a degree of polymerization of 1700.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com