Seawater and coral sand mixed red mud-coal gangue based geopolymer concrete and preparation method thereof

A technology of coral sand and coal gangue, applied in the direction of cement production, etc., to achieve the effect of improving cementation behavior, wide application range and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

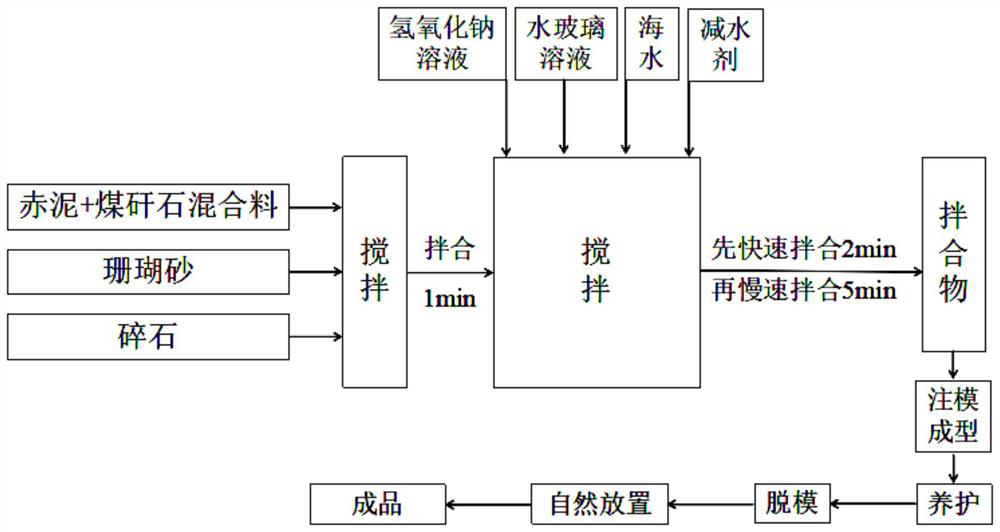

[0043] The concrete preparation steps are as follows:

[0044] Step 1: prepare artificial seawater according to ASTMD1141-2003 standard,

[0045] The proportion of artificial seawater according to the mass ratio is:

[0046] NaCl:Na 2 SO 4 :MgCl 6 h 2 O:KCl:CaCl 2 =24.5:4.1:11.1:0.7:1.2.

[0047] Step 2: Coral sand screened out fine sand, particle size 0.25-0.35mm; gravel is graded gravel, 30% of all gravel mass is between 5-10mm, 70% of all gravel mass is between 10-20mm between.

[0048] Step 3: Break the large pieces of coal gangue into small stones with a particle size of 2-4mm, and then pulverize them.

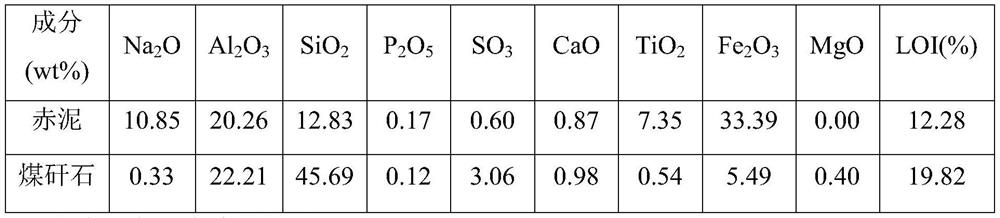

[0049] Step 4: Air-dry the red mud slurry or dry it at 90-100° C. until the water content is lower than 3%, measure its pH value, and then pulverize it. The main purpose of measuring the pH value is to discuss the influence of the alkalinity of the red mud on the reaction and product of the whole geopolymer; generally speaking, the alkalinity of the red mud is wi...

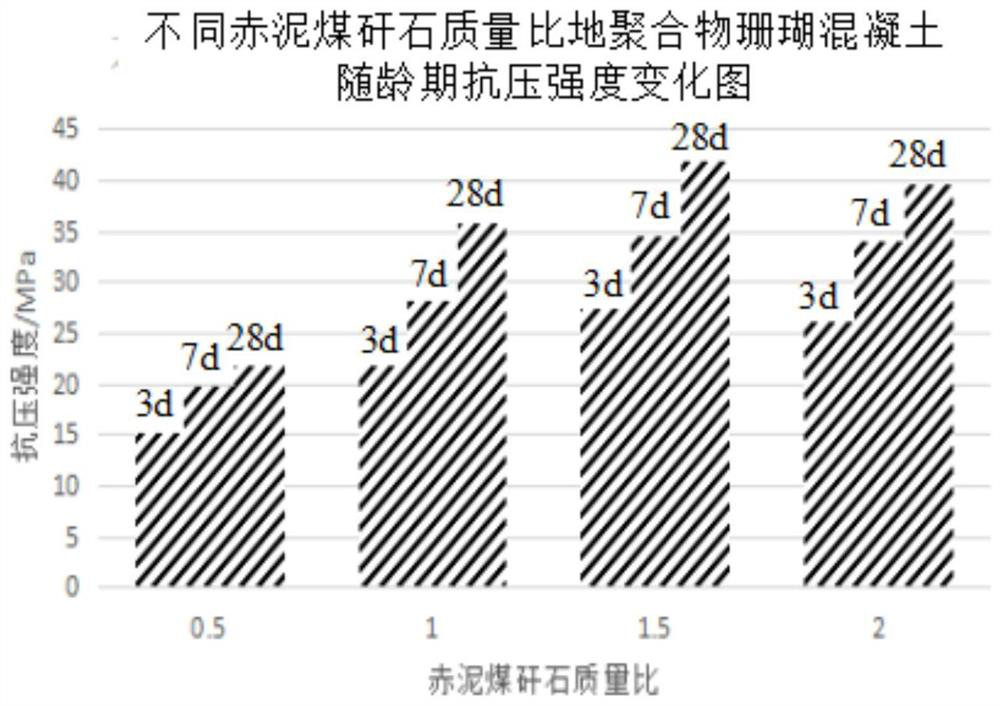

Embodiment 1-4

[0071] Step 1: Prepare artificial seawater according to mass ratio:

[0072] NaCl:Na 2 SO 4 :MgCl 6 h 2 O:KCl:CaCl 2 =24.5:4.1:11.1:0.7:1.2;

[0073] Step 2: Coral sand screened out fine sand, particle size 0.25-0.35mm; gravel is graded gravel, 30% of all gravel mass is between 5-10mm, 70% of all gravel mass is between 10-20mm between;

[0074] Step 3: breaking the large pieces of coal gangue into small stones with a particle size of 2-4mm, and then pulverizing them;

[0075] Step 4: Air-dry the red mud slurry or dry it at 90-100°C until the moisture content is lower than 3%, and its pH value is measured to be 9-11, and then crush it;

[0076] Step 5: Make red mud-coal gangue mixed raw materials; the mass ratio of the two is 1:2.3-2.3:1, add 20%-30% deionized water, knead into a ball with a diameter of 2-3cm, put Dry it in an oven at 90-100°C to remove its free water, then put it in a muffle furnace for calcination at 600-750°C for 2 hours, take it out and cool it, put...

Embodiment 2

[0088] Example 2, step 5 is to put it in an oven to dry at 90°C to remove its free water, and then put it into a muffle furnace for calcination at 600°C for 2h; step 6 is to mix solid sodium hydroxide with ordinary water to make 5mol / l The sodium hydroxide solution; Step 7 is that the water glass modulus is allocated to 1.6 by sodium hydroxide solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com