Preparation method of cobalt disulfide/carbon hollow nanoflower composite material and prepared composite material

A composite material, hollow nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as hindering the continuous application of cobalt disulfide, low electronic conductivity, poor cycle stability, etc. , to achieve the effect of improving electrochemical stability, large specific surface area, and increasing effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

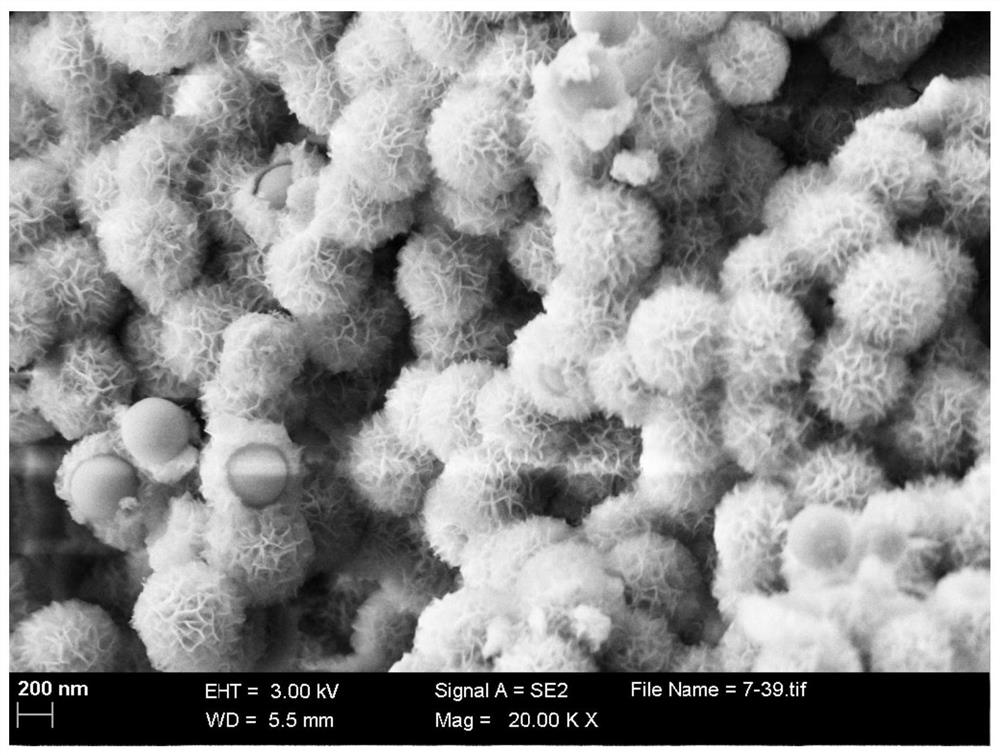

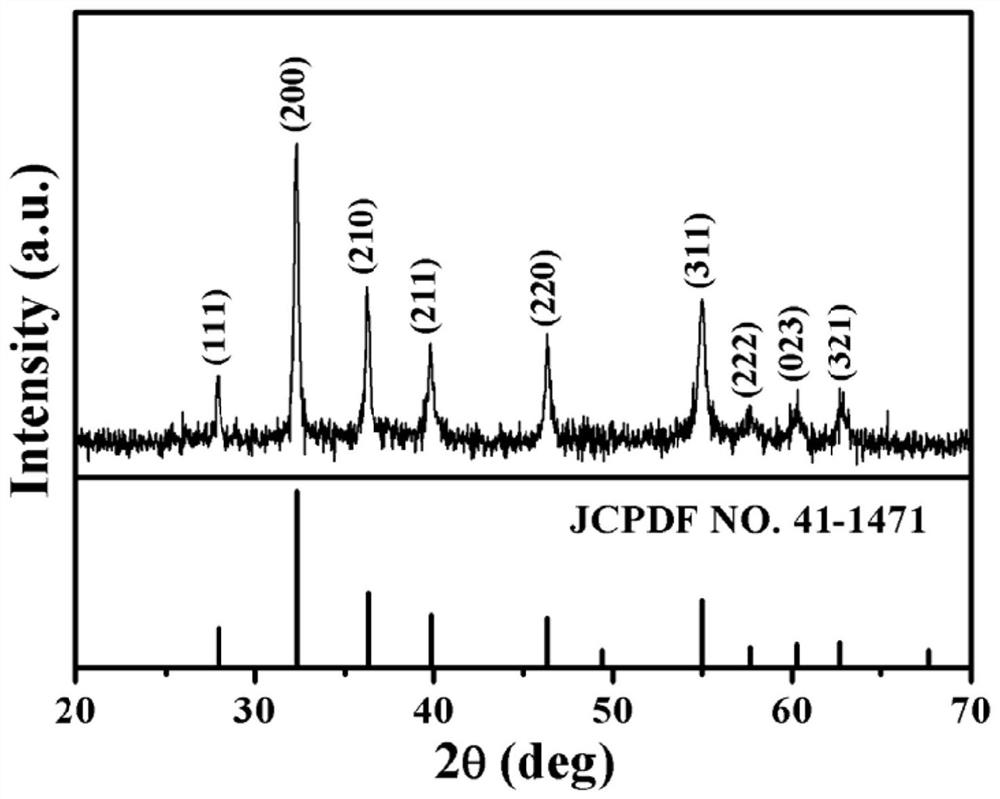

[0045] (1) Add 0.4 ml of tetraethyl orthosilicate dropwise to a mixed solution of 10 ml of water and 70 ml of absolute ethanol, then add 6 ml of ammonia solution and stir for 2 hours, and the resulting precipitate is centrifuged, washed, and dried to obtain a uniform size of silica nanospheres;

[0046] (2) Ultrasonic disperse 0.4 gram of silica nanospheres prepared in step (1) into 60 milliliters of deionized water, then add 2 grams of urea and 0.002 mol of cobalt nitrate and stir to obtain a mixed solution;

[0047] (3) Move the mixed solution obtained in step (2) into the reaction kettle, then place the reaction kettle in a drying oven for 100°C hydroheating, and centrifuge, wash and dry the obtained precipitate to obtain silicic acid with a core-shell structure Cobalt salt / silica composite;

[0048] (4) Disperse 0.4 gram of cobalt silicate / silicon dioxide composite material with core-shell structure obtained in step (3) in 300 milliliters of deionized water, then add 0.00...

Embodiment 2

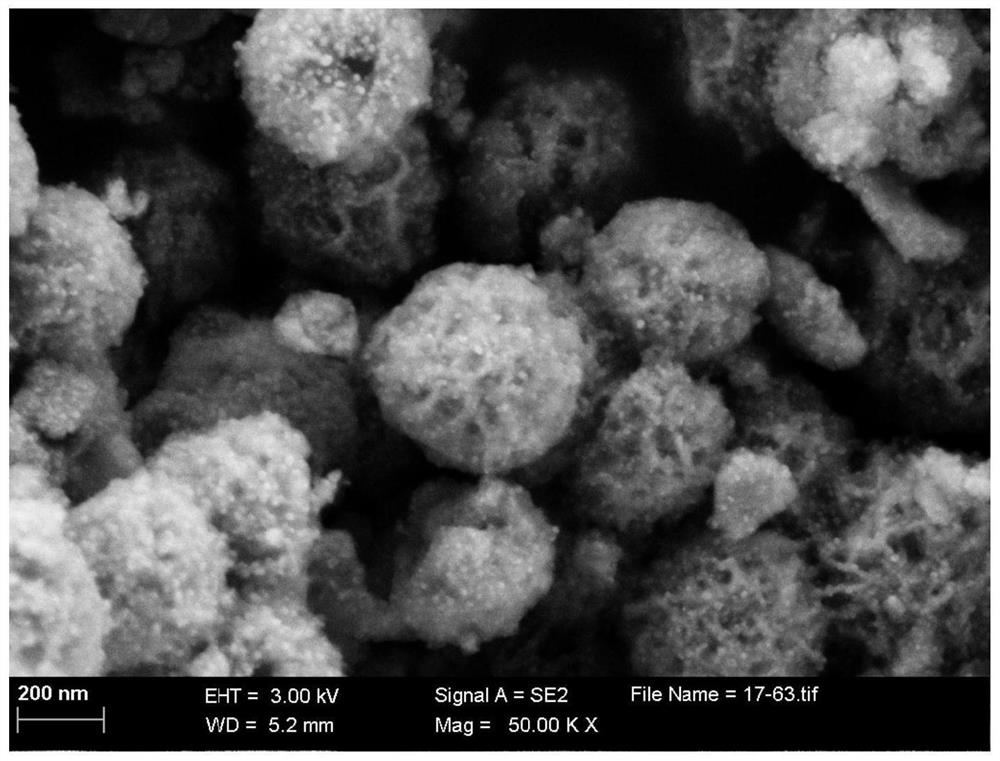

[0053] (1) Add 0.4 ml of tetraethyl orthosilicate dropwise to a mixed solution of 10 ml of water and 70 ml of absolute ethanol, then add 6 ml of ammonia solution and stir for 2 hours, and the resulting precipitate is centrifuged, washed, and dried to obtain a uniform size of silica nanospheres;

[0054] (2) ultrasonically disperse 0.4 gram of silica nanospheres prepared in step (1) into 60 milliliters of deionized water, then add 2 grams of urea and 0.002 mol of cobalt chloride and stir to obtain a mixed solution;

[0055] (3) Move the mixed solution obtained in step (2) into the reaction kettle, then place the reaction kettle in a drying oven for 90°C hydroheating, and centrifuge, wash and dry the obtained precipitate to obtain silicic acid with a core-shell structure Cobalt salt / silica composite;

[0056] (4) Disperse 0.4 gram of cobalt silicate / silicon dioxide composite material with core-shell structure obtained in step (3) in 300 ml of deionized water, then add 0.0016mol...

Embodiment 3

[0061] (1) Add 0.4 ml of tetraethyl orthosilicate dropwise to a mixed solution of 10 ml of water and 70 ml of absolute ethanol, then add 6 ml of ammonia solution and stir for 2 hours, and the resulting precipitate is centrifuged, washed, and dried to obtain a uniform size of silica nanospheres;

[0062] (2) ultrasonically disperse 0.4 gram of silica nanospheres prepared in step (1) into 60 milliliters of deionized water, then add 2 grams of urea and 0.0025 mol of cobalt nitrate for stirring to obtain a mixed solution;

[0063] (3) Move the mixed solution obtained in step (2) into the reaction kettle, then place the reaction kettle in a drying oven for 90°C hydroheating, and centrifuge, wash and dry the obtained precipitate to obtain silicic acid with a core-shell structure Cobalt salt / silica composite;

[0064] (4) Disperse 0.4 gram of cobalt silicate / silicon dioxide composite material with core-shell structure obtained in step (3) in 300 milliliters of deionized water, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com