Enteric coated nano zinc oxide particles and production method thereof

A nano-zinc oxide and production method technology, applied in the direction of adding food elements, forming or processing animal feed, animal feed, etc., can solve the problems of increasing the difficulty of feed formula design, reducing the stability of vitamins, and affecting the luster of animal fur. Achieve strong intestinal astringent protection effect, increase the dissolution rate, and inhibit the damage of viruses and harmful bacteria to the animal body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

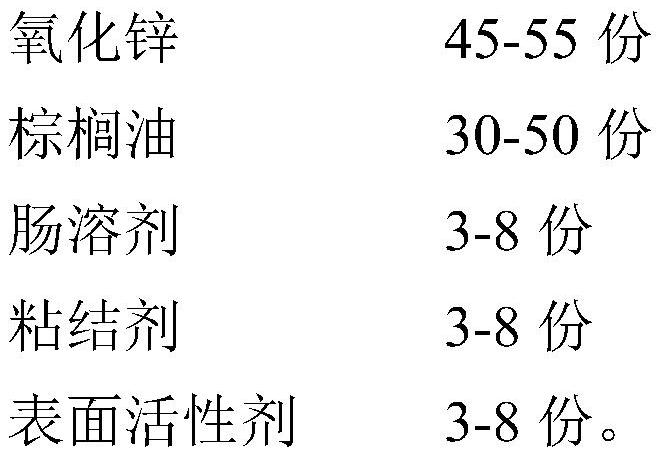

[0029] The product consists of the following components, in parts by weight:

[0030]

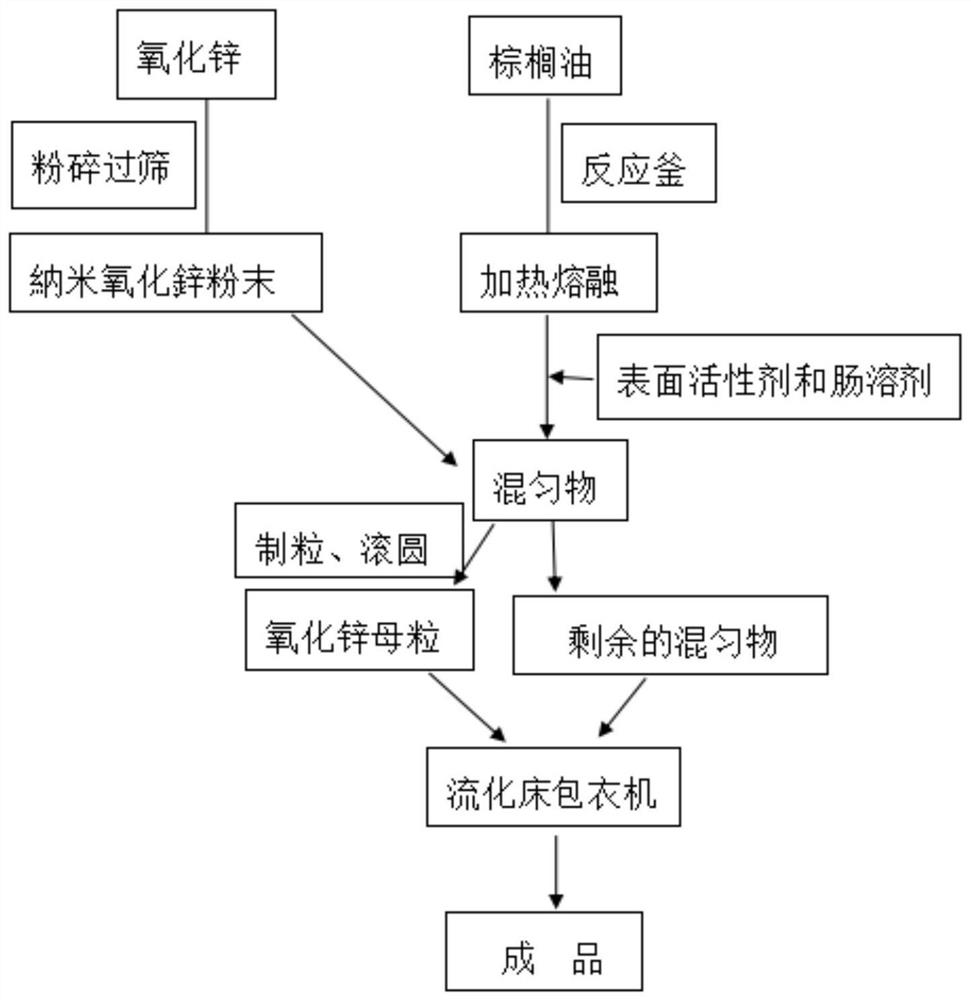

[0031] The palm oil is put into a reaction kettle and heated and melted until the palm oil is stirred evenly. After the temperature is stabilized, a surfactant and an enteric solvent are added and mixed to obtain a homogeneous product; the stirring temperature is 80-90°C.

[0032] Add 5% of the mixed material in step 1 to the crushed and sieved nano-zinc oxide raw material, and perform granulation and spheronization.

[0033] Put the dried zinc oxide masterbatch into the fluidized bed coating machine, turn on the fan, and then spray the remaining mixture of palm oil, surfactant and No. II polyacrylic resin enteric solution onto the zinc oxide masterbatch through a spray gun at a uniform speed , and finally obtain the finished product.

[0034] The process parameters of the fluidized bed coating machine granulation are: control the temperature in the fluidized bed at 35°C, keep the tempe...

Embodiment 2

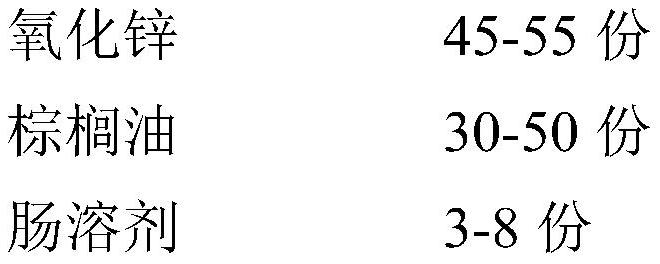

[0036] The product consists of the following components, in parts by weight:

[0037]

[0038] The palm oil is put into a reaction kettle and heated and melted until the palm oil is stirred evenly. After the temperature is stable, a surfactant and an enteric solvent are added and mixed to obtain a homogeneous product, which is then used; the stirring temperature is 80-90°C.

[0039] Add 10% of the mixed material in step 1 to the crushed and sieved nano-zinc oxide raw material, and perform granulation and spheronization.

[0040] Put the dried zinc oxide masterbatch into the fluidized bed coating machine, turn on the fan, and then spray the remaining mixture of palm oil, surfactant and No. II polyacrylic resin enteric solution onto the zinc oxide masterbatch through a spray gun at a uniform speed , and finally obtain the finished product.

[0041] The process parameters of the fluidized bed coating machine granulation are: control the temperature in the fluidized bed at abo...

Embodiment 3

[0043] The product consists of the following components, in parts by weight:

[0044]

[0045] The dosage of No. II polyacrylic resin enteric solution is 10% of the dry granule mass.

[0046] The palm oil is put into a reaction kettle and heated and melted until the palm oil is stirred evenly. After the temperature is stable, a surfactant and an enteric solvent are added and mixed to obtain a homogeneous product, which is then used; the stirring temperature is 80-90°C.

[0047] Add 12% of the mixed material in step 1 to the crushed and sieved nano-zinc oxide raw material, and perform granulation and spheronization.

[0048] Put the dried zinc oxide masterbatch into the fluidized bed coating machine, turn on the fan, and then spray the remaining mixture of palm oil, surfactant and No. II polyacrylic resin enteric solution onto the zinc oxide masterbatch through a spray gun at a uniform speed , and finally obtain the finished product.

[0049] The process parameters of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com