Nitrogen-resistant aromatic hydrocarbon hydrocracking catalyst and its preparation method and application

A hydrocracking and catalyst technology, which is applied in the field of oil refining and hydrocracking, can solve the problems of insufficient nitrogen resistance of aromatic hydrocarbon hydrocracking catalysts, low yield of aromatic hydrocarbons and light hydrocarbon chemical materials, etc. The effect of raw material adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

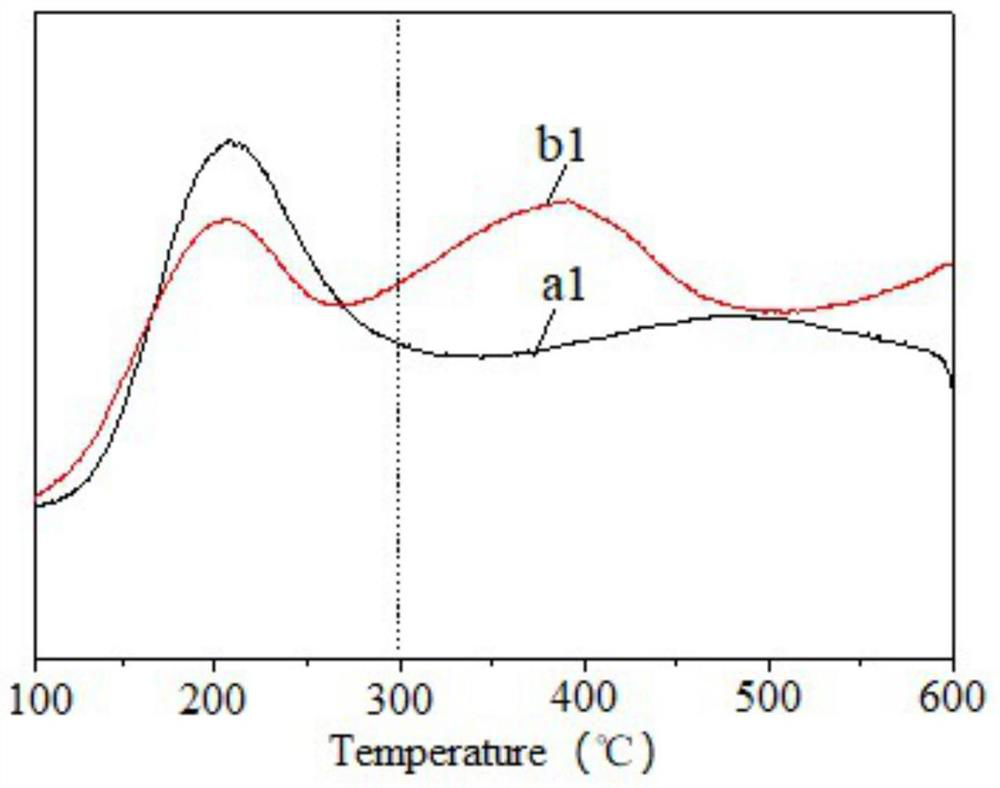

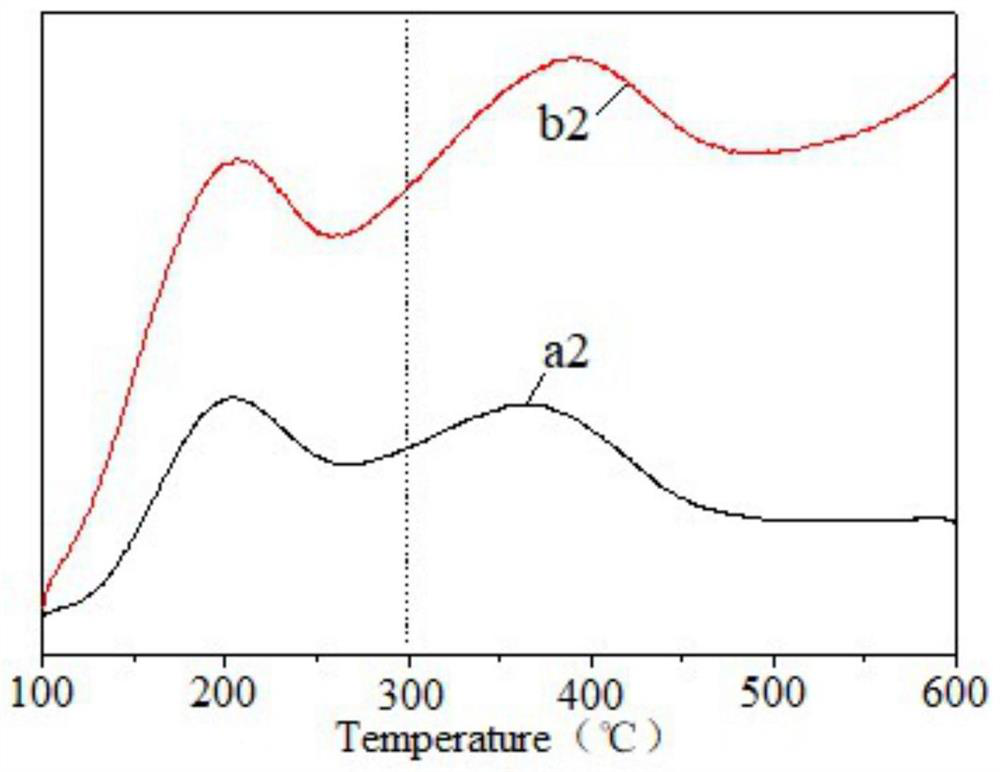

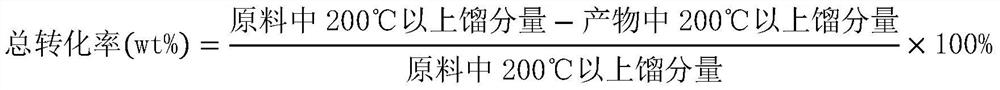

[0093] Take 100 g of the same hydrogen-type beta zeolite (silicon-aluminum ratio SAR=28, SI is 13.01) as in Comparative Example 2, add 800 ml of water, and then add 23 g of citric acid, and stir uniformly. The temperature was raised to 150°C in a self-pressure stirring vessel and kept for 4 hours, and then the temperature was lowered to 30°C, filtered, washed, and dried for use. Its spatial index was 15.18 as determined by standard methods. carry out NH 3 -TPD characterization, the acid amount corresponding to the desorption peak at 300-500 °C accounts for 65% of the total acid amount, see figure 1 .

[0094] 67g of beta zeolite with a dry content of 90%, treated with the above-mentioned polybasic acid, 37g of pseudo-boehmite with a dry content of 70%, and 20g of amorphous silica-alumina (SiO 2 Content 6wt%, dry basis content 80%) through kneading, extrusion molding. It was incubated at room temperature for 24h, dried at 90°C for 12h, and calcined at 550°C for 4h in an air...

Embodiment 2

[0100] In Example 1, 67 g of beta zeolite with a dry basis content of 90% and treated with polybasic acid and 57 g of pseudo-boehmite with a dry basis content of 70% were kneaded and extruded into strips. It was incubated at room temperature for 24h, dried at 90°C for 12h, and calcined at 550°C for 4h in an air atmosphere to obtain a hydrocracking catalyst carrier. 6.4g of nickel nitrate, 7.8g of ammonium molybdate and 20ml of ammonia water were dissolved in water to obtain 50ml of aqueous solution. Take 50 g of hydrocracking catalyst carrier, add 40 ml of solution in an equal volume dipping method, let stand for 3 hours, dry at 110 °C for 12 hours, and calcinate at 500 °C for 4 hours in an air atmosphere to obtain a hydrocracking catalyst precursor.

[0101] Catalyst pre-sulfidation (according to the usual sulfidation procedure of hydrocracking catalysts): inject cyclohexane solution containing 0.5% carbon disulfide into a fixed-bed reactor equipped with hydrocracking catalys...

Embodiment 3

[0107]Take 67 g of beta zeolite with a dry basis content of 90% and treated with polybasic acid in Example 1, and knead and extrude it with 57 g of pseudo-boehmite with a dry basis content of 70%. It was incubated at room temperature for 24h, dried at 90°C for 12h, and calcined at 505°C for 6h in an air atmosphere to obtain a hydrocracking catalyst carrier. Chloroplatinic acid and palladium chloride are prepared into a clear solution, and the above carrier is impregnated by an equal volume, then dried at 100° C. and calcined in air at 460° C. for 6 hours to obtain a catalyst precursor.

[0108] The catalyst precursor was reduced to 480 °C under hydrogen conditions and kept for 12 h to obtain catalyst C5 with a composition of 0.05wt% Pt-0.15wt%Pd / 59.8wt%β-40wt%Al 2 O 3 , see Table 2.

[0109] Feed 2, nitrogen content of 7.4 ppm, was continuously injected into a fixed bed reactor packed with catalyst C5. The reaction conditions are: temperature 410°C, pressure 6.0MPa, LHSV sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com