Catalyst for acetylene hydrochlorination reaction and application thereof

An acetylene hydrochlorination and catalyst technology, applied in physical/chemical process catalysts, catalyst activation/preparation, organic chemistry, etc., can solve problems such as endangering human health, environmental pollution, etc., to promote dispersion and firm loading, and improve activity. and stabilizing and increasing the effect of the active center site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

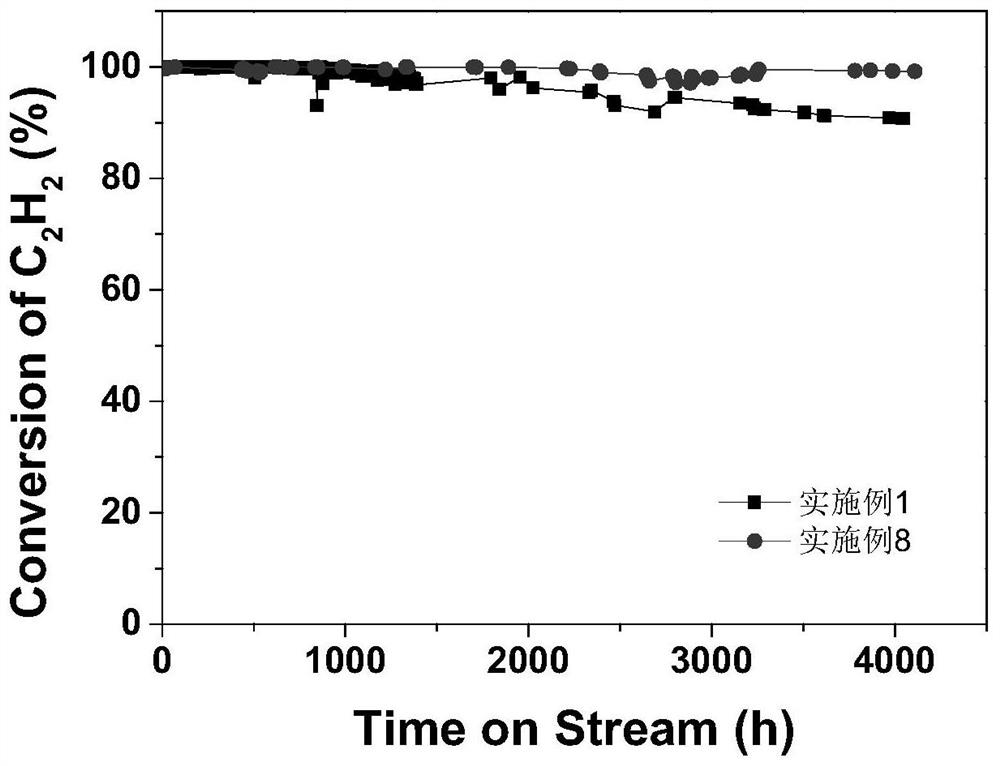

Image

Examples

Embodiment 1

[0020] 1. Weigh the specific surface area of 850m 2 Add 50.0g of flaky coconut shell activated carbon per g into a flask filled with 250mL mass concentration of 15% ammonia solution, then place the flask in a microwave radiator with a frequency of 2450MHz, set the power to 650W, and control the temperature to 85 ℃, microwave radiation for 2.5h, then the obtained mixed slurry was subjected to vacuum filtration, washed with deionized water until the pH of the filtrate was neutral, and then the filter cake was dried to a constant weight in a blast oven at 120°C to obtain pretreated activated carbon.

[0021] 2. At room temperature, add 30.0g of pretreated activated carbon to 22mL of sodium hyposulfite aqueous solution with a mass concentration of 2.5%, soak for 45min, then add 10mL of gold trichloride hydrochloric acid aqueous solution containing 0.3g of gold, and let stand for 12h , remove excess liquid, and transfer the remaining solid particles to a blast drying oven at 120...

Embodiment 2

[0023] 1. Weigh the specific surface area of 850m 2 Add 50.0g of flaky coconut shell activated carbon per g into a flask filled with 500mL mass concentration of 10% ammonium bicarbonate aqueous solution, then place the flask in a microwave radiator with a frequency of 2450MHz, and set the power to 750W to control the temperature 75°C, microwave radiation for 8h, then vacuum-filter the obtained mixed slurry, wash with deionized water until the pH of the filtrate is neutral, and then place the filter cake in a 120°C blast drying oven to dry to constant weight, Get pretreated activated carbon.

[0024] 2. At room temperature, add 40.0g of pretreated activated carbon to 28mL of potassium persulfate aqueous solution with a mass concentration of 4%, soak for 35min, then add 5mL of gold trichloride aqueous hydrochloric acid solution containing 0.05g of gold, and let it stand After 10 hours, the excess liquid was removed, and the remaining solid particles were transferred to a blas...

Embodiment 3

[0026] 1. Weigh the specific surface area of 850m 2 Add 50.0g of flaky coconut shell activated carbon per g into a flask filled with 500mL of ammonium hydrogen phosphate solution with a mass concentration of 5%, then place the flask in a microwave radiator with a frequency of 2450MHz, set the power to 850W, and control the temperature 95°C, microwave irradiation for 5.5h, then vacuum filter the obtained mixed slurry, wash with deionized water until the pH of the filtrate is neutral, and then place the filter cake in a 120°C blast drying oven to dry to constant weight , to obtain pretreated activated carbon.

[0027] 2. At room temperature, add 30.0 g of pretreated activated carbon to 22 mL of potassium thiosulfate aqueous solution with a mass concentration of 2%, soak for 60 minutes, then add 10 mL of gold trichloride aqueous hydrochloric acid solution containing 0.06 g of gold, and statically Set aside for 18 hours, remove the excess liquid, and transfer the remaining soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com