Strain for preventing and treating greenhouse tomato continuous cropping common diseases and composite microbial agent thereof

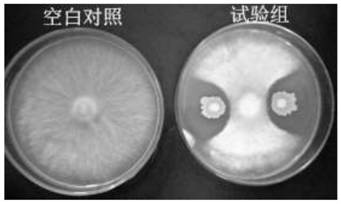

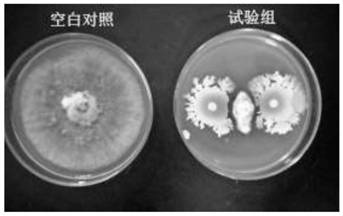

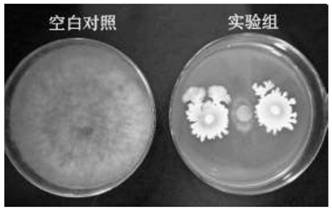

A compound microbial agent and tomato technology, applied in the direction of microorganisms, biocides, and methods based on microorganisms, can solve problems such as human health and environmental safety hazards, pathogenic bacteria resistance, and chemical residues in the environment, etc., to achieve recovery and stability Bacterial flora balance, less drug resistance, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 composite microbial bacterial agent

[0043] The YJY19-01 strain and the YJY20-02 strain were subjected to fermentation and expansion culture respectively. The culture conditions were: the aeration ratio of sterile air was 1:1.0, the stirring speed was 250rpm, the culture temperature was 37°C, and the fermentation period was 30h. The spore rate is not less than 80%.

[0044] Wherein, the culture medium is corn flour soybean flour medium, and its composition and weight percentage are: soybean meal 6.86%, corn flour 5.5%, ammonium sulfate 0.04%, corn starch 0.46%, manganese sulfate 0.05%, calcium carbonate 0.3%, Corn steep liquor dry powder 0.17%, the rest is water, pH7.2.

[0045] A. After the expanded culture is completed, the bacterial liquid is mixed according to the effective live bacteria amount of 1:1 to obtain a liquid composite microbial agent against common pathogens of repeated cropping, and the effective live bacteria amount is...

Embodiment 2

[0048] The preparation of embodiment 2 composite microbial bacterial agents

[0049] The YJY19-01 strain and the YJY20-02 strain were subjected to fermentation and expansion culture respectively. The culture conditions were: the aeration ratio of sterile air was 1:1.5, the stirring speed was 200rpm, the culture temperature was 35°C, and the fermentation period was 33h. The spore rate is not less than 80%.

[0050] Wherein, the culture medium is corn flour and soybean flour medium, and its composition and weight percentage are: 6.5% of soybean meal, 5% of corn flour, 0.1% of ammonium sulfate, 0.55% of corn starch, 0.034% of manganese sulfate, 0.1% of calcium carbonate, Corn steep liquor dry powder 0.3%, the rest is water, pH7.0.

[0051] A. After the expanded culture is completed, the bacterial liquid is mixed according to the effective live bacteria amount of 1:1 to obtain a liquid composite microbial agent against common pathogens of repeated cropping, and the effective live...

Embodiment 3

[0054] The preparation of embodiment 3 composite microbial bacterial agents

[0055] The YJY19-01 strain and the YJY20-02 strain were subjected to fermentation and expansion culture respectively. The culture conditions were: the aeration ratio of sterile air was 1:2.0, the stirring speed was 300rpm, the culture temperature was 33°C, and the fermentation period was 35h. The spore rate is not less than 80%.

[0056] Wherein, the culture medium is corn flour soybean flour medium, and its composition and weight percentage are: 6% soybean meal, 4.5% corn flour, 0.08% ammonium sulfate, 0.8% corn starch, 0.04% manganese sulfate, 0.25% calcium carbonate, Corn steep liquor dry powder 0.45%, the rest is water, pH7.4.

[0057] A. After the expanded culture is completed, the bacterial liquid is mixed according to the effective live bacteria amount of 1:1 to obtain a liquid composite microbial agent against common pathogens of repeated cropping, and the effective live bacteria amount is ≥...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com