Zero-discharge treatment equipment and method for semi-coke wastewater

A technology for blue carbon wastewater and treatment equipment, which is applied in water/sewage treatment equipment, water/sewage treatment, water treatment parameter control, etc. , to achieve the effect of improving processing efficiency, good extraction effect and ensuring extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

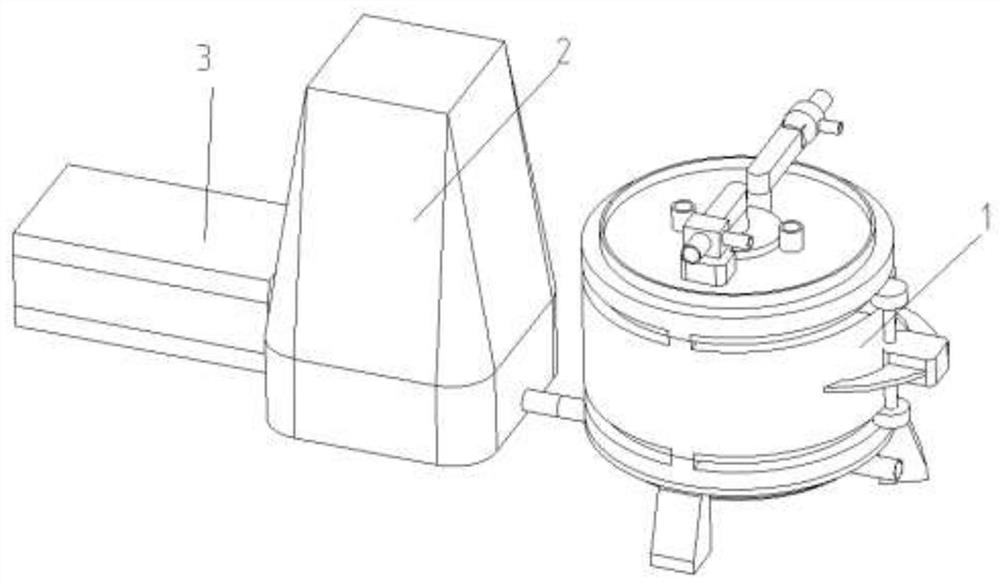

[0048] Embodiment 1: as figure 1 The zero-discharge treatment equipment for semi-coke wastewater includes sequentially connected pretreatment modules, a first treatment module 1, a deamination module 2, a second treatment module 3, and an AO biochemical treatment module;

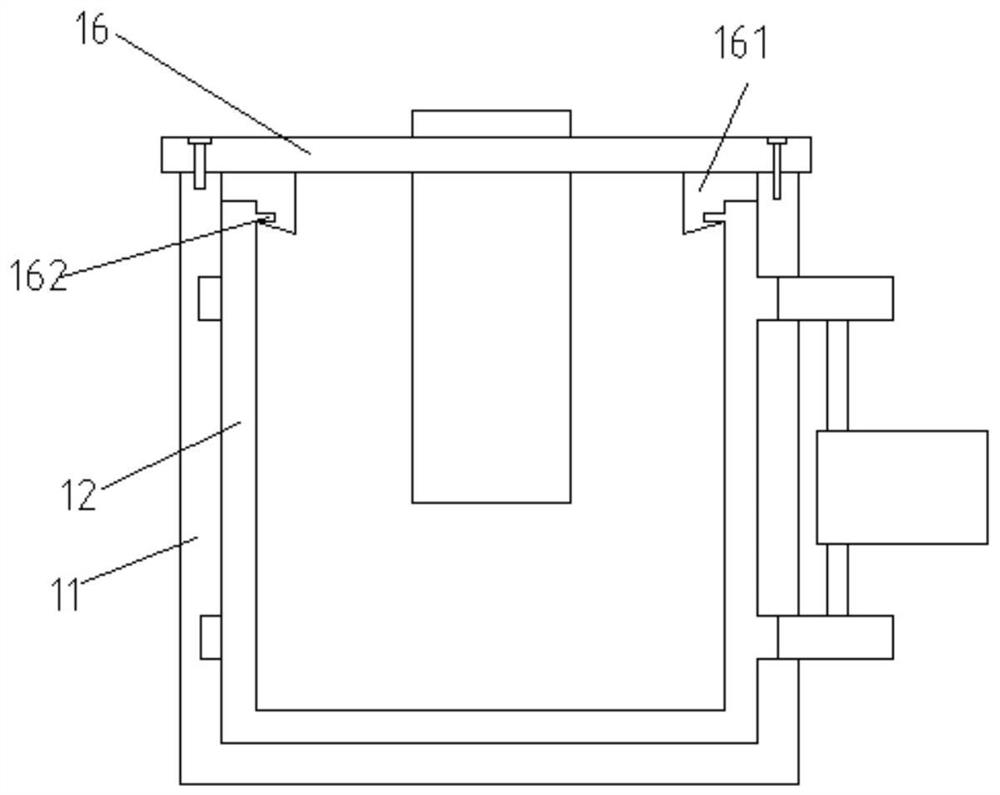

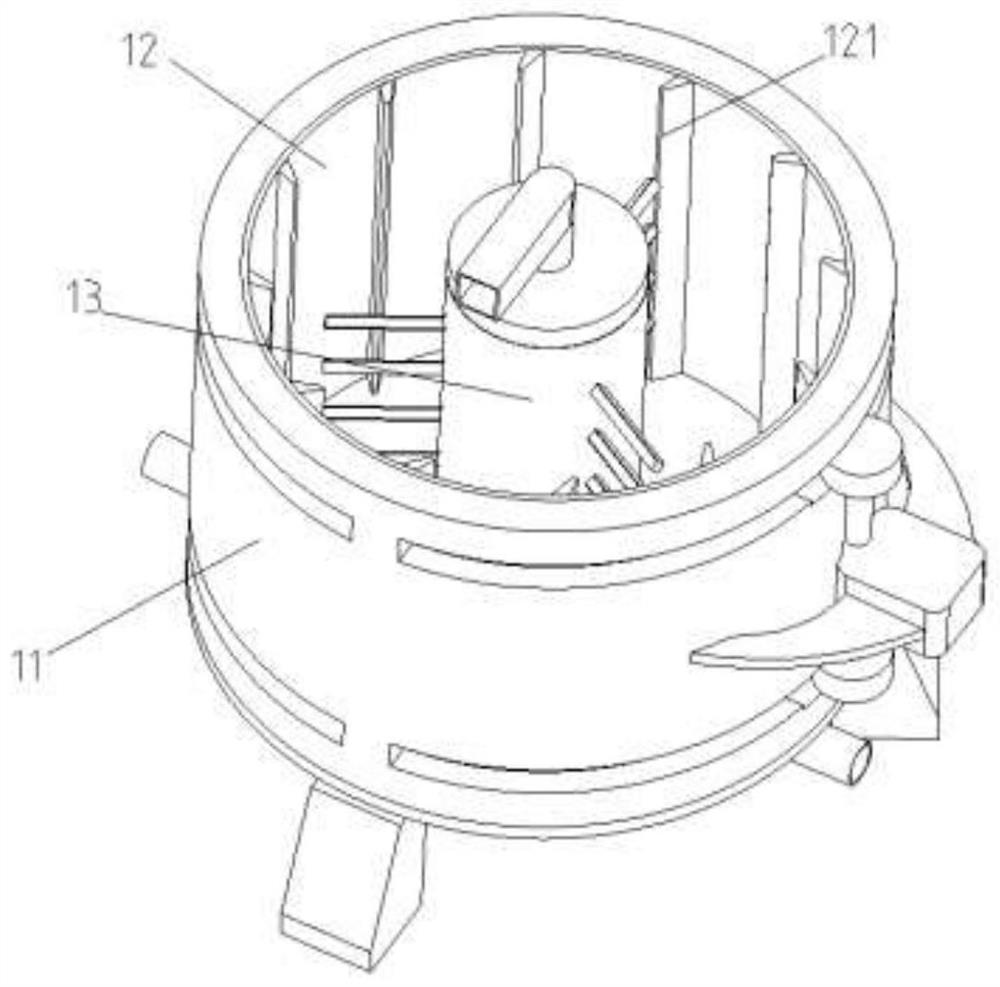

[0049] Such as figure 2 The shown first processing module 1 includes a processing housing assembly, and a processing assembly installed on the processing housing assembly; the processing housing assembly includes a bracket, a circular tank 11 installed on the bracket, and a circular tank 11 installed on the The sealing cover 16 at the upper end, the rotating cylinder 12 that is movably installed on the sealing cover 16, and the power assembly that is installed on the circular tank body 11 to provide power to the rotating cylinder 12;

[0050] The upper end of the sealing cover 16 and the circular tank body 11 is fixedly connected by bolts, and the lower end of the sealing cover 16 is provided with a leak-p...

Embodiment 2

[0079] Embodiment 2: different from embodiment 1, a kind of zero-discharge treatment method of blue charcoal wastewater comprises the following steps:

[0080] Step 1. Preprocessing

[0081] Preliminary precipitation and filtration of cinder pollutants in semi-coke wastewater;

[0082] Step 2. Synchronous treatment of oil removal and phenol removal

[0083] Pass the pretreated semi-coke wastewater and polyaluminum chloride demulsifier into the mixer 141 for mixing and then enter the rotating cylinder 12; wherein, the volume ratio of the dosage of polyaluminum chloride demulsifier to the semi-coke wastewater is 0.8 g / L;

[0084] Then add the complex extractant with a volume ratio of 1:2 to the inside of the rotating cylinder 12 through the extractant feeding assembly 15; then add the sulfuric acid with a mass fraction of 98% in the rotating drum 12 through the sulfuric acid feeding assembly until The pH of the mixture is 3; the stirring blade is stirred for 30 minutes;

[0...

Embodiment 3

[0092] Embodiment 3: different from embodiment 1, a kind of zero-discharge treatment method of blue charcoal wastewater comprises the following steps:

[0093] Step 1. Preprocessing

[0094] Preliminary precipitation and filtration of cinder pollutants in semi-coke wastewater;

[0095] Step 2. Synchronous treatment of oil removal and phenol removal

[0096] Pass the pretreated semi-coke wastewater and polyaluminum chloride demulsifier into the mixer 141 for mixing and then enter the rotating cylinder 12; wherein, the volume ratio of the dosage of polyaluminum chloride demulsifier to the semi-coke wastewater is 0.7 g / L;

[0097] Then add the complex extractant with a volume ratio of 1:2 to the inside of the rotating cylinder 12 through the extractant feeding assembly 15; then add the sulfuric acid with a mass fraction of 88% in the rotating drum 12 through the sulfuric acid feeding assembly until The pH of the mixture is 2; the stirring blade is stirred for 25 minutes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com