A kind of anti-spatter tin wire for electronic packaging and preparation method thereof

An electronic packaging and anti-splash technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as poor solder joint firmness, welding spatter, and different expansion coefficients, so as to improve anti-splash performance and reduce production costs , improve the splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

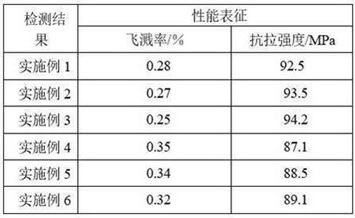

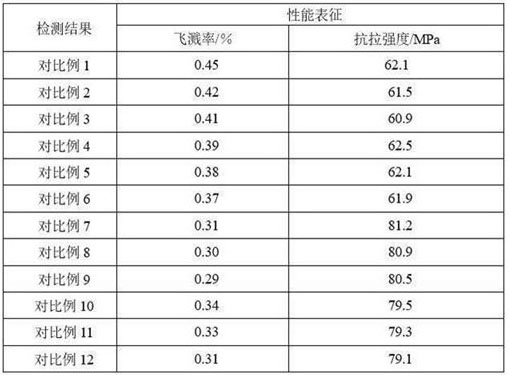

Examples

Embodiment 1

[0030] According to the mass ratio of 1:5:20, polyvinyl alcohol and polyglycerol ester were added to deionized water, stirred and mixed and placed at 75°C for thermal insulation and dissolution, and the dissolved solution was collected; 1:15, add monoglyceride to the molten beeswax, stir and mix and ultrasonically disperse for 10min, collect the emulsion, control the dropping ratio to be 1:3 by mass ratio, add the dissolved dropwise to the emulsion, at 55 Incubate the reaction at ℃ for 3h, stand to cool to room temperature, separate and collect the upper layer solidified body to obtain modified beeswax;

[0031] According to the mass ratio of 1:1, the rosin and toluene were mixed and placed at 65 °C for 25 minutes, and the mixed stirring liquid was collected and 45 mL of the mixed stirring liquid, 1 g of zinc chloride and 3 mL of 0.5 mol / L sulfuric acid were respectively weighed. Under a nitrogen atmosphere, react in an oil bath at 125 °C for 6 hours, stand to cool to room tempe...

Embodiment 2

[0037] According to the mass ratio of 1:5:20, polyvinyl alcohol and polyglycerol ester were added to deionized water, stirred and mixed, and placed at 80 °C for insulation and dissolution, and the dissolved solution was collected; 1:15, add monoglyceride to molten beeswax, stir and mix and ultrasonically disperse for 12min, collect the emulsion, control the dropping ratio to be 1:3 by mass ratio, add the dissolved dropwise to the emulsion, at 58 Incubate the reaction at ℃ for 4h, stand to cool to room temperature, separate and collect the upper layer solidified body to obtain modified beeswax;

[0038] According to the mass ratio of 1:1, the rosin and toluene were mixed and kept at 70°C for 27 minutes, and the mixed stirring liquid was collected and weighed respectively 47 mL of the mixed stirring liquid, 1 g of zinc chloride and 4 mL of 0.5 mol / L sulfuric acid. Under a nitrogen atmosphere, react in an oil bath at 127°C for 7 hours, stand to cool to room temperature and filter...

Embodiment 3

[0044] According to the mass ratio of 1:5:20, polyvinyl alcohol and polyglycerol ester were added to deionized water, stirred and mixed, and placed at 85 °C for insulation and dissolution, and the dissolved solution was collected; 1:15, add the monoglyceride to the molten beeswax, stir and mix and ultrasonically disperse for 15min, collect the emulsion, control the dropping ratio to be 1:3 by mass ratio, add the dissolved dropwise to the emulsion, at 60 Incubate the reaction at ℃ for 5h, stand to cool to room temperature, separate and collect the upper layer solidified body to obtain modified beeswax;

[0045] According to the mass ratio of 1:1, mix the rosin and toluene and keep stirring at 75°C for 25-30 minutes, collect the mixed stirring liquid and weigh 50 mL of the mixed stirring liquid, 2 g of zinc chloride and 5 mL of 0.5 mol / L sulfuric acid, respectively, and stir. Mixed and placed under nitrogen atmosphere, reacted in oil bath at 130°C for 8 hours, left to cool to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com