Preparation method of electronic-grade copper chloride dehydrate

A copper chloride dihydrate, electronic-grade technology, applied in copper chloride, copper halide and other directions, can solve the problems of high equipment requirements, long process flow, high cost of raw materials, and achieves low environmental pollution, simple preparation process operation, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

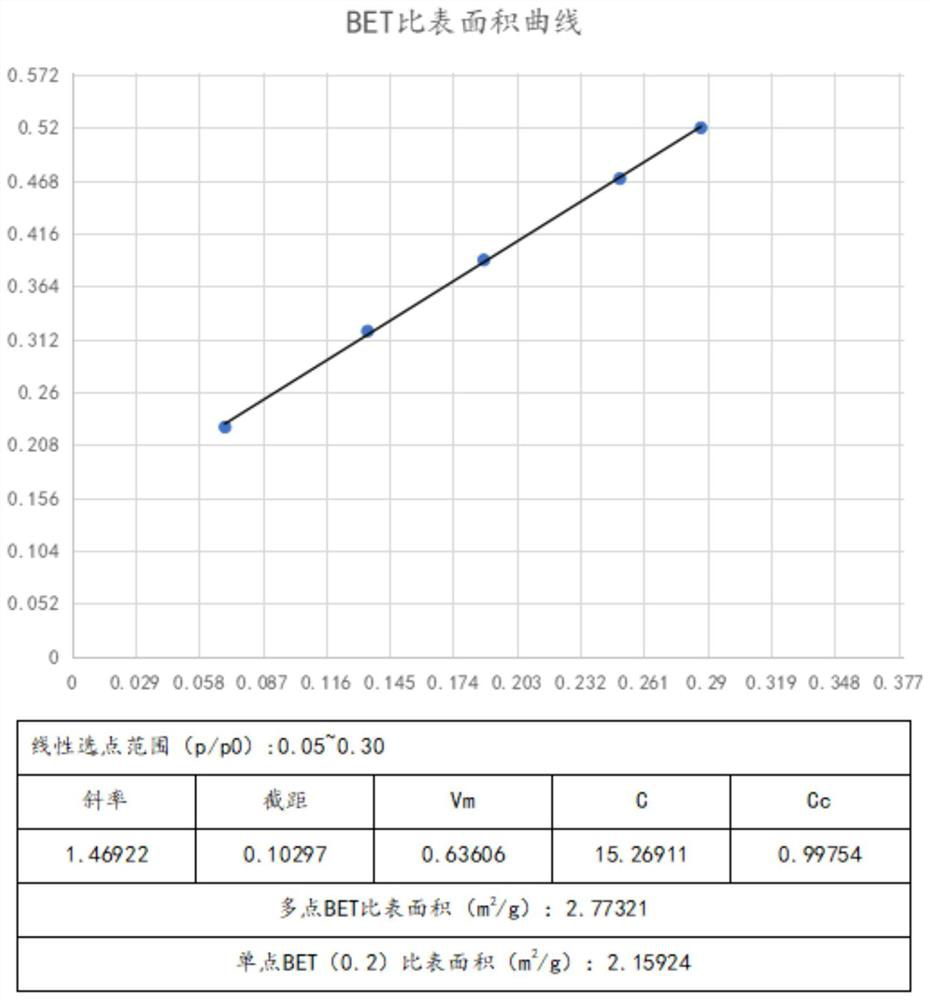

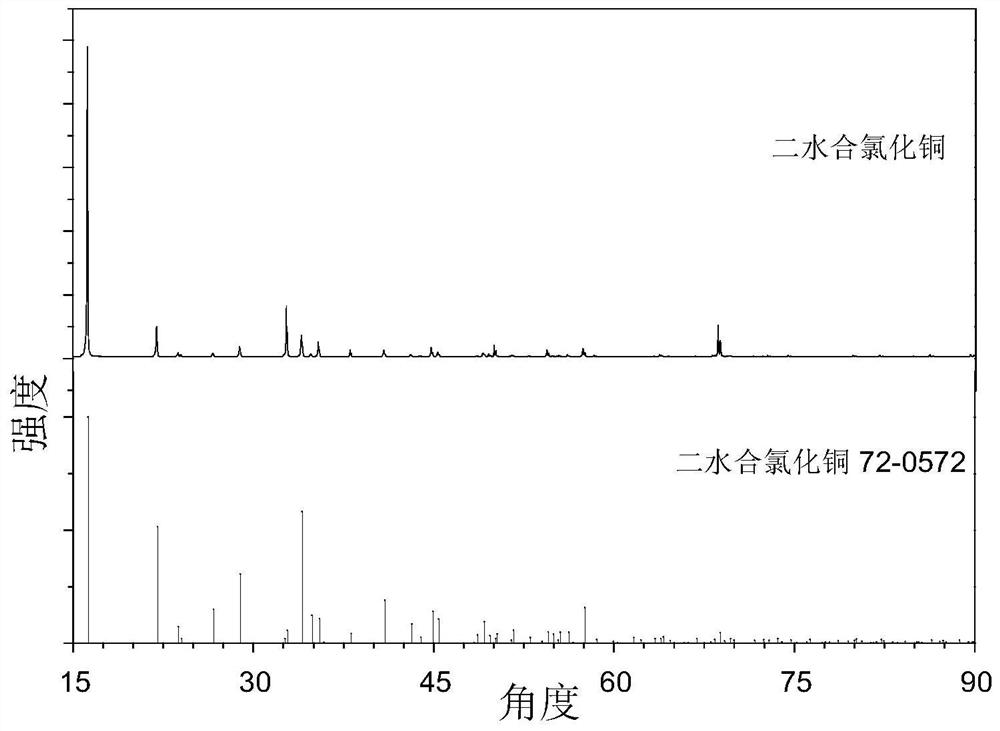

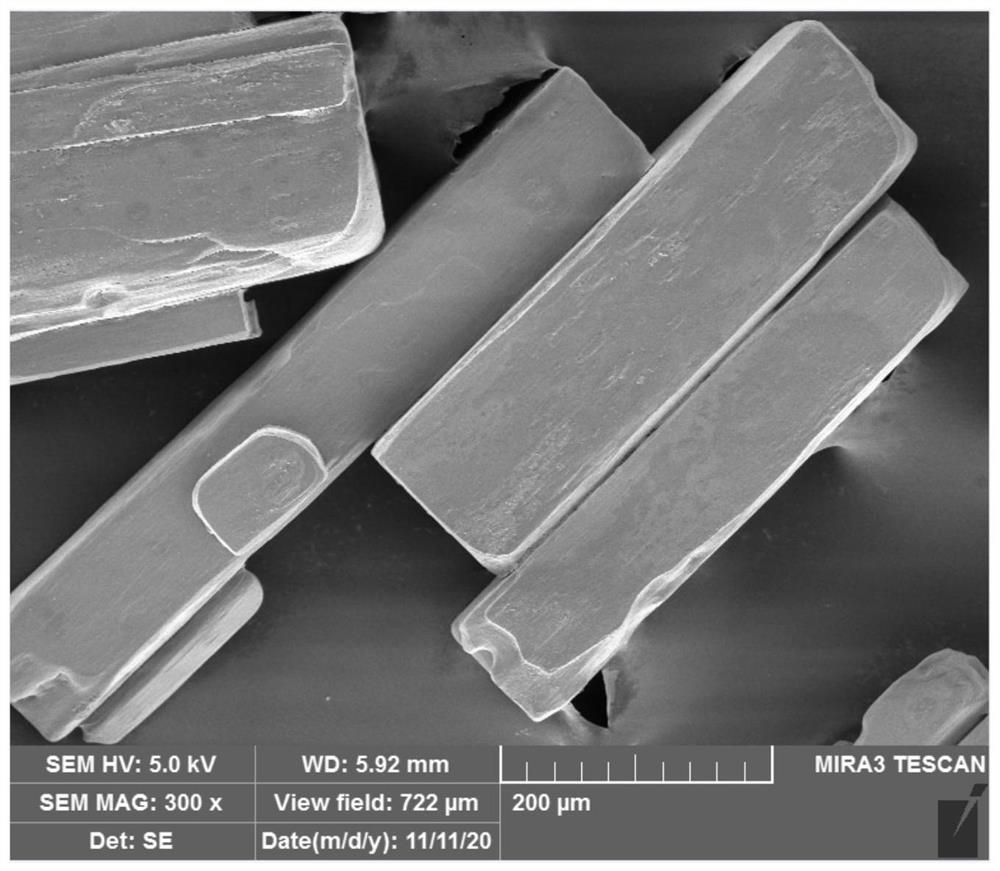

Image

Examples

Embodiment 1

[0036] The copper salt used in this embodiment is basic copper chloride, which has a mass of 640 g, a copper content of 59.25%, an iron content of 132 mg / kg, a nickel content of 31.9 mg / kg, and a zinc content of 2.9 mg / kg.

[0037] (1) Obtain 640g basic copper chloride, completely dissolve in the first hydrochloric acid solution with a mass of 1152g and a mass fraction of 30.0%, to obtain a copper salt solution;

[0038] (2) Add 5.76g of waste PCB board powder to the copper salt solution, continue stirring for 40min and then filter,

[0039] Put the filtered solution in a water bath at 90°C, add 2.3g of anhydrous tin chloride and continue to stir for 30min before filtering to obtain the filtrate;

[0040] (3) After adding the second hydrochloric acid to the filtrate to adjust the pH to 1.0, keep the temperature of the filtrate at 95°C, evaporate and concentrate to a supersaturated solution, add 23g copper chloride seed crystals, stir and cool for 8h, and centrifuge to obtain e...

Embodiment 2

[0047] The copper salt used in this embodiment is copper hydroxide, its mass is 195g, the copper content is 64.23%, the iron content is 103 mg / kg, the nickel content is 13 mg / kg, and the zinc content is 9.6 mg / kg.

[0048] The difference between this embodiment and Example 1 is: in step (1), the copper salt obtained is copper hydroxide, and its quality is 195g, and the first hydrochloric acid quality is 1060g, and the mass fraction is 12.67%; Step (2) In the process, the quality of the waste PCB board powder added is 21g, and the continuous stirring time after adding the waste PCB board powder is 10min, the temperature of the water bath is 80°C, the added tin chloride compound is tin tetrachloride tetrahydrate, and its mass is 3.2g, adding The stirring time after the tin chloride compound is 120 min; in step (3), the pH is adjusted to 1.5, the evaporation concentration temperature is 80° C., the mass of copper chloride seed crystals is 32 g, and the stirring and cooling time is...

Embodiment 3

[0050] The copper salt used in this embodiment is copper oxide with a mass of 298g, a copper content of 78.04%, an iron content of 126 mg / kg, a nickel content of 16 mg / kg, and a zinc content of 11.8 mg / kg.

[0051] The difference between this embodiment and Example 1 is: in step (1), the copper salt obtained is copper oxide, its quality is 298g, and the first hydrochloric acid quality is 1110g, and the mass fraction is 21.7%; In step (2) , the quality of the waste PCB board powder added is 16.7g, after adding the waste PCB board powder, the continuous stirring time is 20min, the temperature of the water bath is 60°C, the tin chloride compound is added as tin protochloride tetrahydrate, its quality is 4.4g, add The stirring time after the tin chloride compound is 90 min; in step (3), the pH is adjusted to 0.75, the evaporation concentration temperature is 85° C., the mass of copper chloride seed crystals is 5.55 g, and the stirring and cooling time is 6 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com