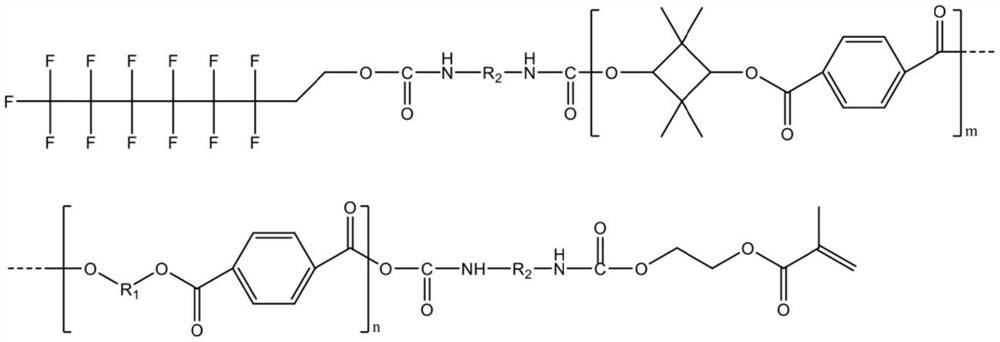

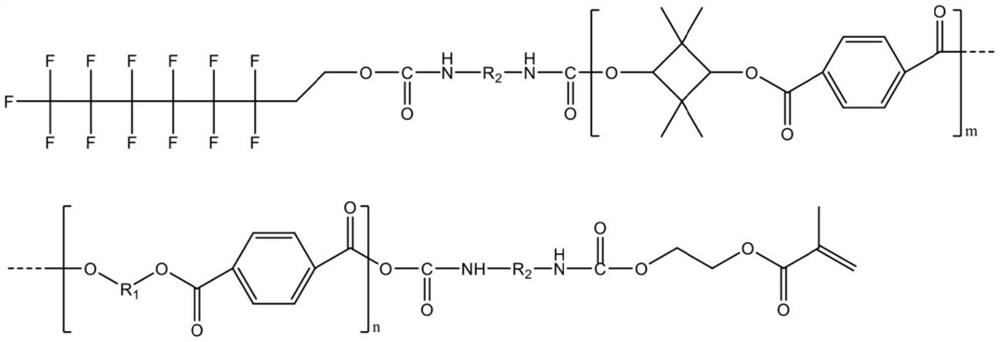

Modified polyester type fluorine-containing urethane acrylate polymer as well as synthesis and application thereof

A polyurethane acrylate and modified polyester technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited high-temperature applications, low glass transition temperature, poor hydrophobicity and weather resistance, and achieve impact resistance High strength, high glass transition temperature, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

[0059] Unless otherwise stated, the content percentages of all components in this specification are percentages by weight, ie wt.%.

[0060] 1. Synthesis of modified polyester fluorine-containing polyurethane acrylate

[0061] Example 1 - Resin A

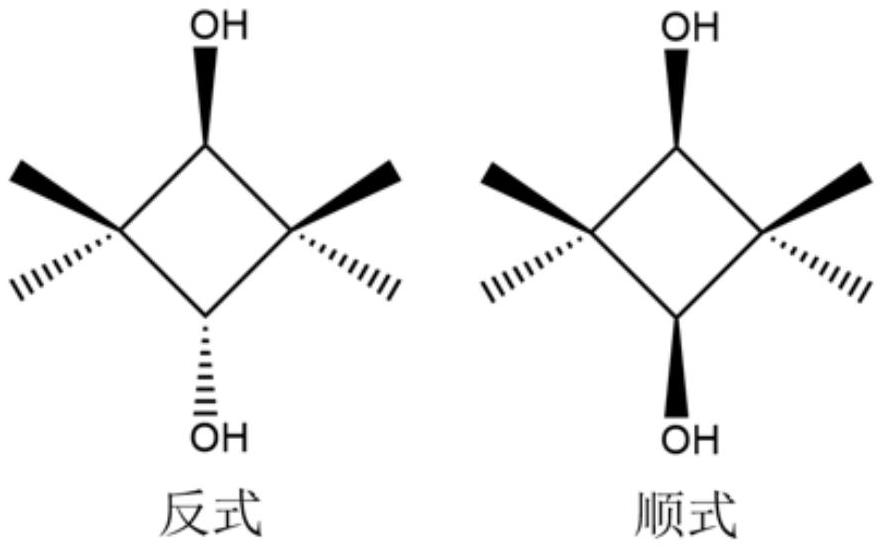

[0062] (1) Synthesis of new copolyester [(CBDO-DMT)-co-(DMT-BDO)] polyol backbone

[0063] Add terephthalate (DMT) and 2,2,4,4-tetramethyl-1,3-cyclobutanediol (CBDO) into the three-necked flask respectively, raise the temperature to 120°C, and wait for the reaction After the system becomes a uniform molten state, the catalyst dibutyltin oxide is added. Argon gas was introduced to keep the reaction system in an inert atmosphere, and then the temperature was raised to 180° C., and the methanol obtained in the reaction was distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com