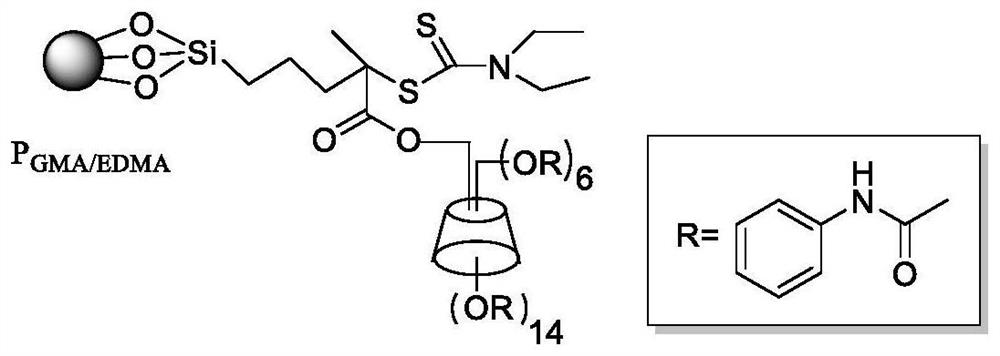

A monodisperse β-cyclodextrin functionalized polymer microsphere chiral stationary phase and its preparation method and application

A technology of chiral stationary phase and cyclodextrin, which is applied in the field of chromatographic stationary phase, can solve the problems of complex preparation process, limited application of ATRP method, difficult removal, etc., and achieve simple preparation method, improved π-π interaction, and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

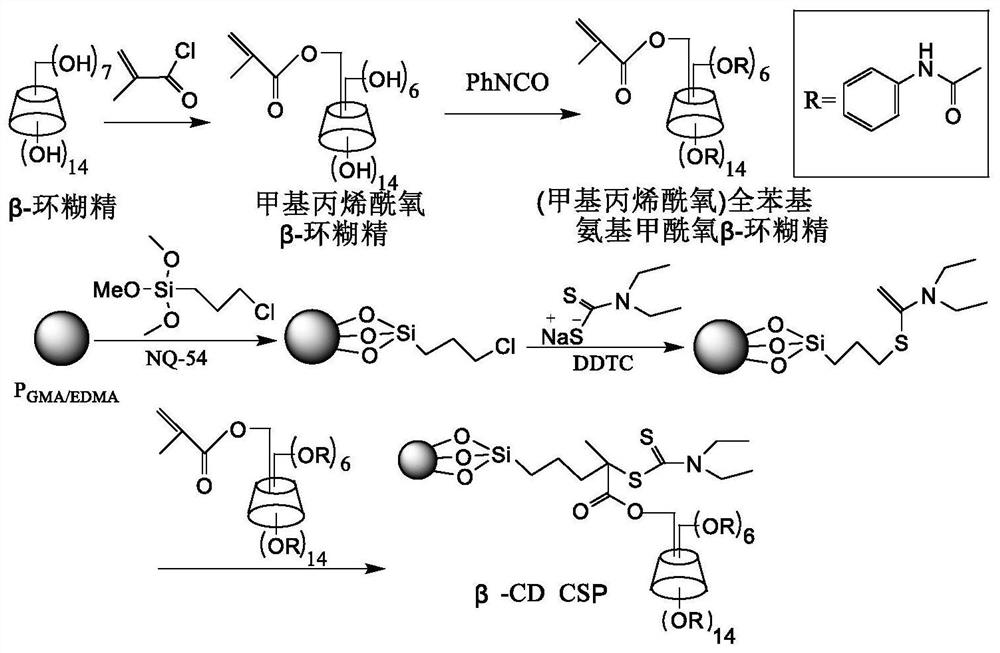

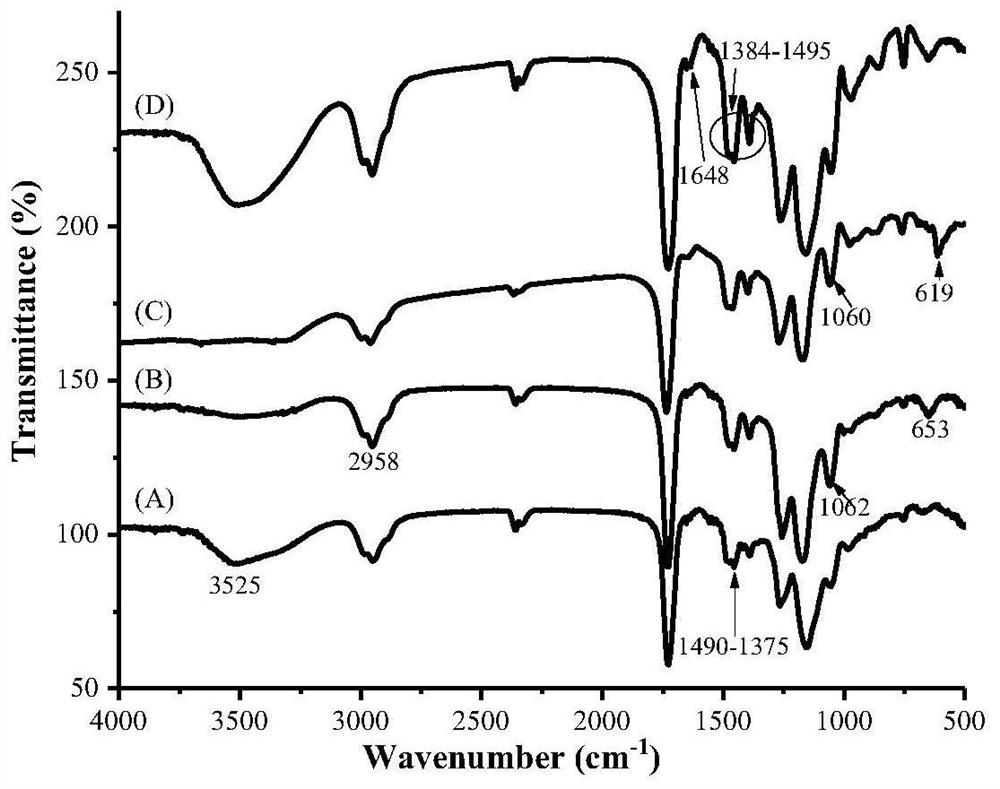

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of monodisperse magnetic chiral stationary phase, concrete steps are as follows:

[0041] A method for preparing a monodisperse β-cyclodextrin functionalized polymer microsphere chiral stationary phase, the specific steps are as follows:

[0042] (1) Preparation of seed liquid of monodisperse polyglycidyl methacrylate: Take 5 mL of glycidyl methacrylate, 0.1 g of azobisisobutyronitrile and 1.0 g of polyvinylpyrrolidone and ultrasonically disperse them in 60 mL of anhydrous In ethanol, put it on a rotary evaporator, under the protection of nitrogen, heat up to 50°C for polymerization reaction for 16 hours, wash the product fully with absolute ethanol, centrifuge, add 30mL sodium dodecyl sulfate solution, put it in the refrigerator and let it settle for 10 hours , to obtain the seed liquid of monodisperse polyglycidyl methacrylate;

[0043] (2) Preparation of monodisperse polyglycidyl methacrylate microspheres: Take 2mL glycidyl methacrylate, 2mL e...

Embodiment 2

[0050] The preparation method of monodisperse magnetic chiral stationary phase, concrete steps are as follows:

[0051] A method for preparing a monodisperse β-cyclodextrin functionalized polymer microsphere chiral stationary phase, the specific steps are as follows:

[0052] (1) Preparation of seed liquid of monodisperse polyglycidyl methacrylate: Take 8 mL of glycidyl methacrylate, 0.15 g of azobisisobutyronitrile and 1.5 g of polyvinylpyrrolidone and ultrasonically disperse them in 75 mL of anhydrous In ethanol, put it on a rotary evaporator, under the protection of nitrogen, heat up to 60°C for polymerization reaction for 24 hours, wash the product fully with absolute ethanol, centrifuge, add 45mL sodium dodecyl sulfate solution, put it in the refrigerator, and settle for 18 hours , to obtain the seed liquid of monodisperse polyglycidyl methacrylate;

[0053] (2) Preparation of monodisperse polyglycidyl methacrylate microspheres: Take 4mL glycidyl methacrylate, 4mL ethyle...

Embodiment 3

[0060] (1) Preparation of seed liquid of monodisperse polyglycidyl methacrylate: take 10mL glycidyl methacrylate, 0.2g azobisisobutyronitrile and 2.0g polyvinylpyrrolidone and ultrasonically disperse them in 90mL of anhydrous In ethanol, place it on a rotary evaporator, under the protection of nitrogen, heat up to 70 ° C for 36 hours of polymerization reaction, wash the product fully with absolute ethanol, centrifuge, add sodium lauryl sulfate solution, place it in the refrigerator, and precipitate for 24 hours. Obtain the seed liquid of monodisperse polyglycidyl methacrylate;

[0061] (2) Preparation of monodisperse polyglycidyl methacrylate microspheres: Take 6mL glycidyl methacrylate, 6mL ethylene glycol dimethacrylate, 6mL toluene, 6mL cyclohexanol and 0.36g azo Diisobutyronitrile is dispersed evenly by ultrasonic, add 35mL of 5% (w / v) polyvinyl alcohol, 75mL of 0.2% (w / v) sodium lauryl sulfate and 45mL of distilled water and mix evenly, put it into the cell disruptor and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com