A rod-shaped valve stem sealant composition and preparation method thereof

A sealant and composition technology, applied in the field of sealing lubricants, can solve the problems affecting the rapid and sensitive switch of blowout preventer valves, poor resistance to medium corrosion, and poor sealing of valve stems, etc., and achieve excellent thermal stability and chemical stability High performance, strong resistance to medium corrosion, fast and sensitive switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

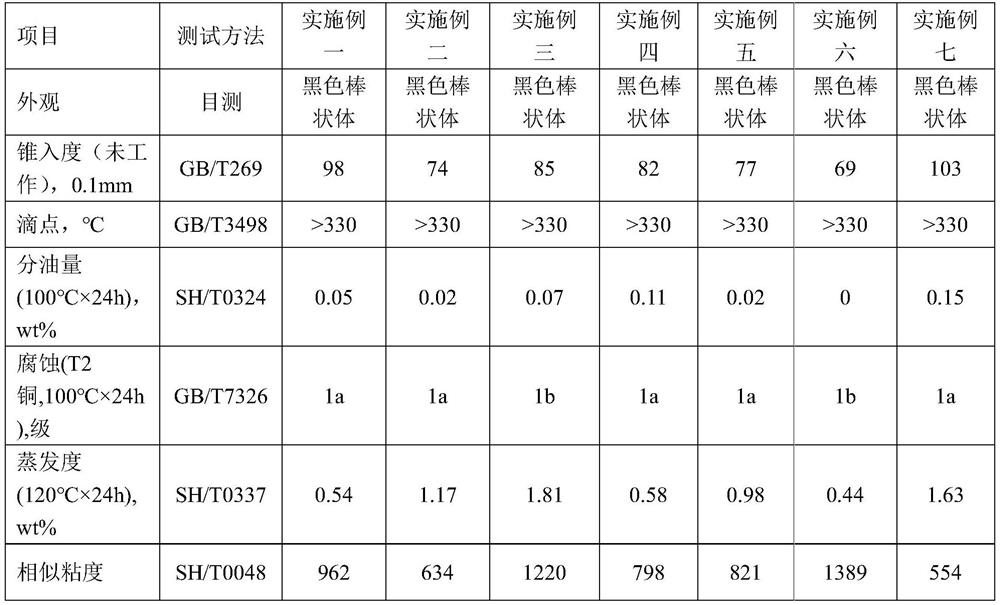

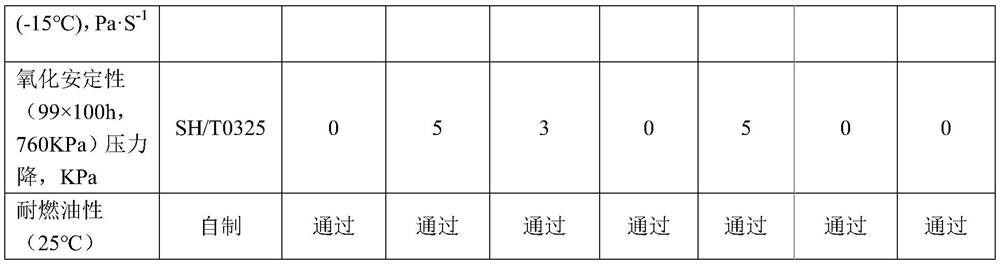

Examples

Embodiment 1

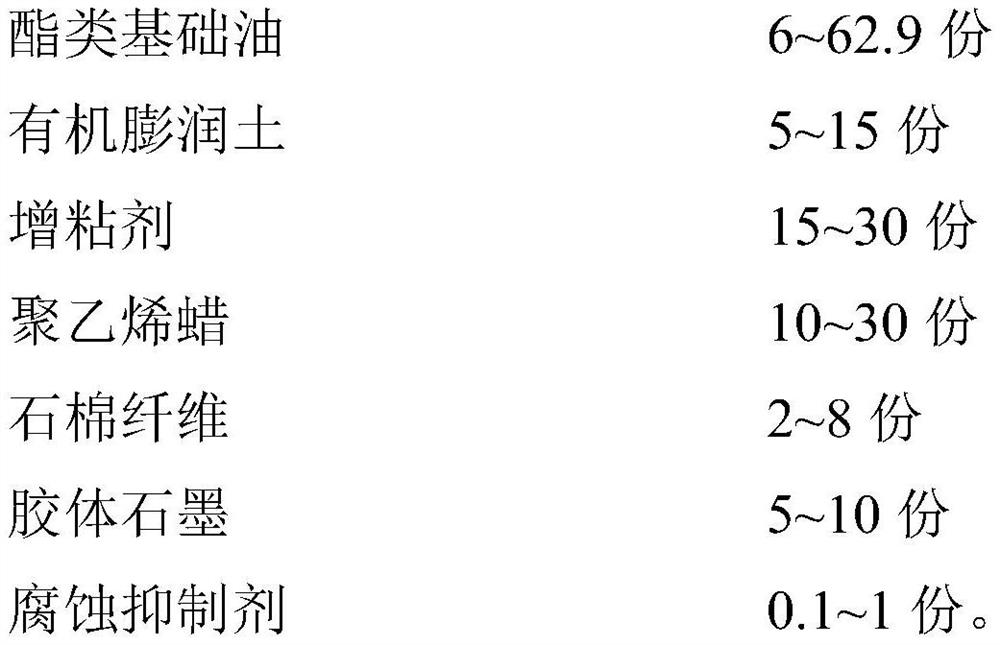

[0032] A rod-shaped valve stem sealing grease composition, the preparation method of which is:

[0033] 1) First, the kinematic viscosity (V 40 =44mm 2 / s), 8 parts of polymethyl methacrylate (V 100 =1320mm 2 / s), 14 parts of low molecular weight polyisobutylene (V100 =3780mm 2 / s) into the reaction kettle together, heating and stirring to 60 ± 5 ° C, constant temperature stirring for 30 ± 5 minutes, so that the base oil and the tackifier are dispersed evenly, and then 11 parts of organic bentonite A (with dimethyl octadecane) are added. benzyl amine chloride covering treatment) and 22 parts polyethylene wax (V 149 =65mm 2 / s), continue to heat up and stir to 130±5°C, and stir at a constant temperature for 45±5 minutes.

[0034] 2) Add 8 parts of colloidal graphite, 5 parts of asbestos fiber and 0.2 part of T551 in turn, stir and disperse for 30±5 minutes, then discharge the material into a barrel, immediately grind it once through a three-roller mill, and hold it into a...

Embodiment 2

[0037] A rod-shaped valve stem sealing grease composition, the preparation method of which is:

[0038] 1) First, the kinematic viscosity (V 40 =90mm 2 / s), 25 parts of low molecular weight polyisobutylene (V 100 =2490mm 2 / s) into the reaction kettle together, heating and stirring to 60 ± 5 ° C, constant temperature stirring for 30 ± 5 minutes, so that the base oil and the tackifier are dispersed evenly, and then 6 parts of organic bentonite A (with dimethyl octadecane) are added. benzyl amine chloride covering treatment), 7 parts of organobentonite B (covering treatment with dimethyl dioctadecyl amine chloride) and 24 parts polyethylene wax (V 149 =92mm 2 / s), continue to heat up and stir to 130±5°C, and stir at a constant temperature for 45±5 minutes.

[0039] 2) Add 7 parts of colloidal graphite, 6 parts of asbestos fiber and 0.5 part of T706 in turn, stir and disperse for 30 ± 5 minutes, then discharge the material into a barrel, immediately grind it once through a t...

Embodiment 3

[0042] A rod-shaped valve stem sealing grease composition, the preparation method of which is:

[0043] 1) First, the kinematic viscosity of 12 parts of C5-C12 saturated fatty acid trimethylolpropane ester (V40=32mm 2 / s), the kinematic viscosity of 17.7 parts of pentaerythritol esters of C5-C12 saturated fatty acids (V40=79mm 2 / s), 22 parts of polymethyl methacrylate (V 100 =1980mm 2 / s) into the reaction kettle together, heating and stirring to 60 ± 5 ° C, constant temperature stirring for 30 ± 5 minutes, so that the base oil and the tackifier are dispersed evenly, and then 15 parts of organic bentonite B (with dimethyl dioctadecane) are added. Alkyl amine chloride covering treatment) and 15 parts polyethylene wax (V 149 =68mm 2 / s), continue to heat up and stir to 130±5°C, and stir at a constant temperature for 45±5 minutes.

[0044] 2) Add 10 parts of colloidal graphite, 8 parts of asbestos fiber and 0.3 part of T561 in turn, stir and disperse for 30±5 minutes, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com