Method for promoting rapid generation of methane hydrate by using carbon nanotube composite hydrogel

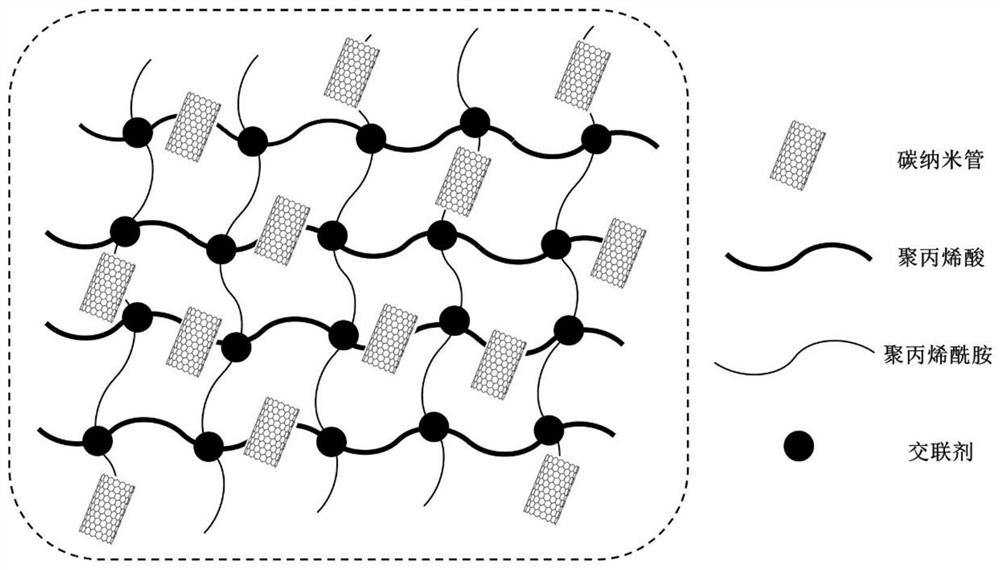

A carbon nanotube composite and methane hydrate technology, which is applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of restricting the rapid progress of hydrogen hydrate reaction, achieve good recycling performance, and improve heat transfer rate. , Principle scientific and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The process of the method for the carbon nanotube composite hydrogel to promote the rapid generation of methane hydrate involved in this embodiment includes three steps: carbon nanotube composite hydrogel, processing carbon nanotube composite hydrogel and generating methane hydrate:

[0026] (1) Preparation of carbon nanotube composite hydrogel:

[0027] Dissolve 8.77g of acrylic acid in 20ml of deionized water, stir until dissolved, and prepare an aqueous solution of acrylic acid; dissolve 3.9g of sodium hydroxide in 20ml of deionized water, stir, and prepare an aqueous solution of sodium hydroxide; Mix and carry out neutralization reaction to obtain a mixed solution with a neutralization degree of 80%;

[0028] Slowly pour the mixed solution into a three-necked flask, place the three-necked flask in an oil bath, raise the temperature to 90°C and keep it there, place a magnetic stirrer on the top, keep the speed at 300rmp, and stir for 5-10min;

[0029] Add 8.77g of a...

Embodiment 2

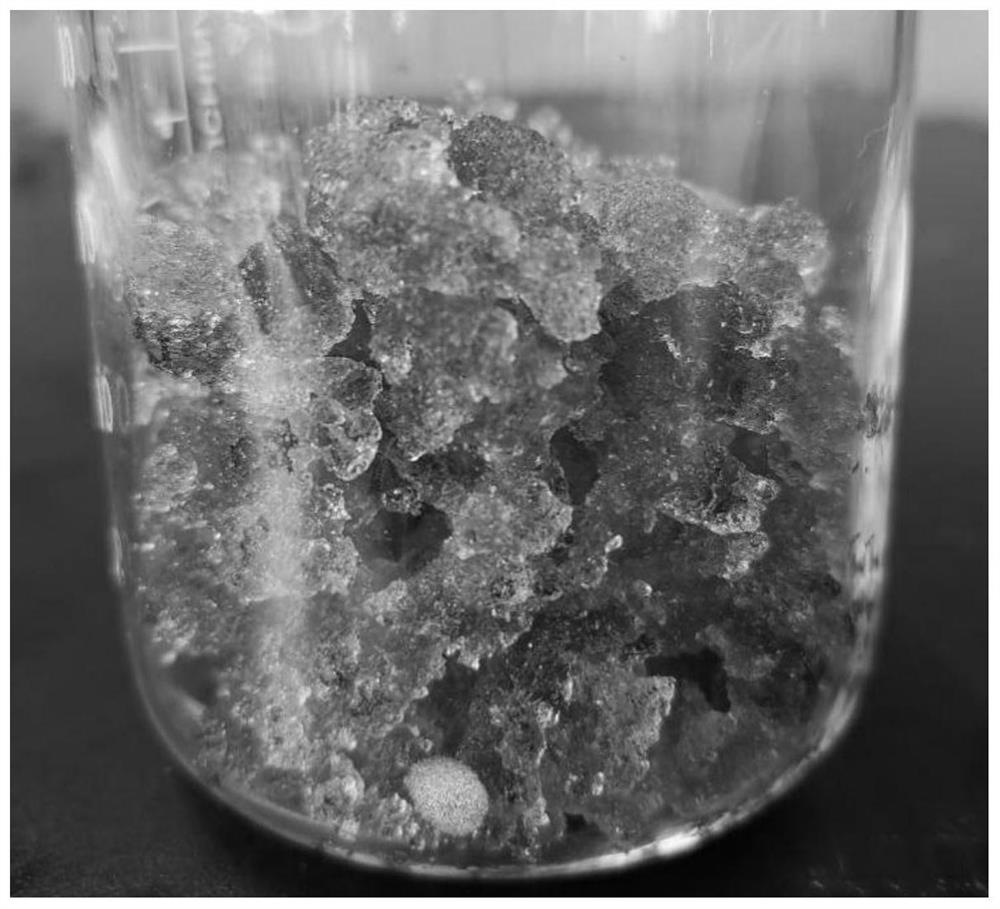

[0038] In this example, the carbon nanotube composite hydrogel prepared in step (1) of Example 1 is subjected to a water absorption swelling test, and the appearance of the carbon nanotube composite hydrogel after absorbing water is as follows: figure 1 As shown, after testing, the water-absorbing-swelling ratio is 132 times.

Embodiment 3

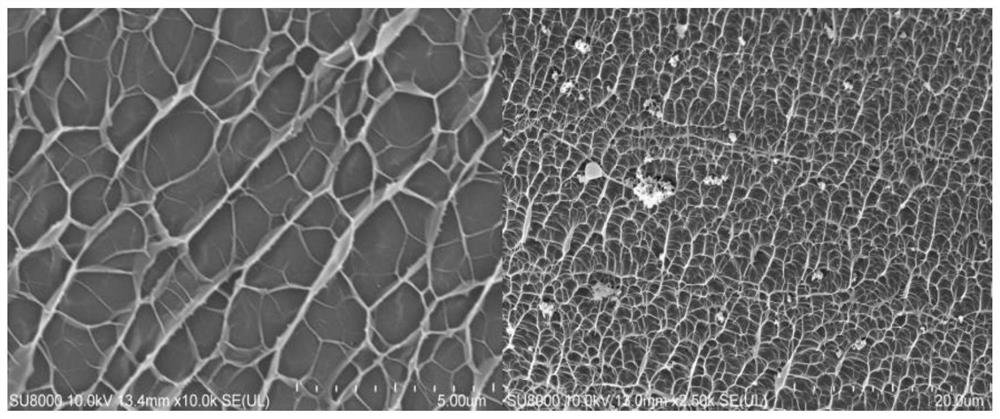

[0040] In this example, the carbon nanotube composite hydrogel particles prepared in step (2) of Example 1 were observed by a scanning electron microscope: 0.1 g of carbon nanotube composite hydrogel particles were placed in 10 g of distilled water to make the carbon nanotube composite hydrogel particles The gel particles fully absorb water until no free-flowing water can be observed. At this time, the water content of the carbon nanotube composite hydrogel particles is 99.01%. Put them in a refrigerator at -6°C for 12 hours, and take out the frozen carbon nanotube composite hydrogel particles. Glue particles, put them into a freeze dryer, and vacuum freeze-dry them for 24-48 hours at a cold trap temperature of -56°C; spray gold on the freeze-dried carbon nanotube composite hydrogel particles, and then observe them with a scanning electron microscope , the captured pictures are as figure 2 As shown, the carbon nanotube composite hydrogel particles after water absorption and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com