Multi-stage structure electrode for electrolyzing water, and preparation method of multi-stage structure electrode

A technology of electrolyzing water and electrodes, which is applied in the field of materials, can solve the problems of poor product stability, high cost, and high stability, and achieve the effects of stable performance, low cost, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

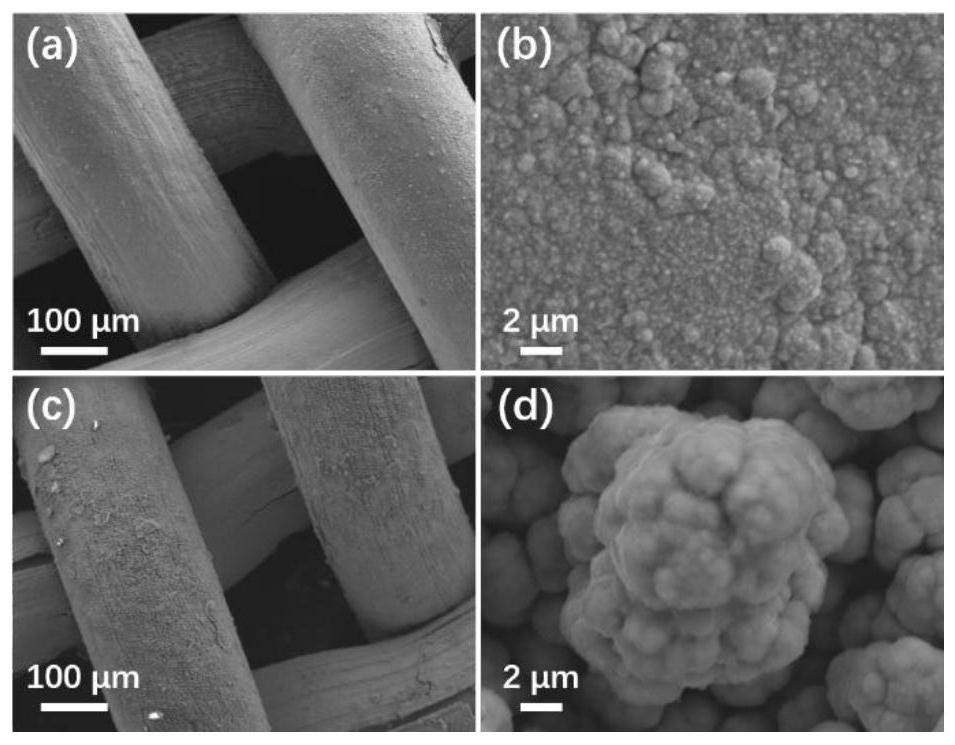

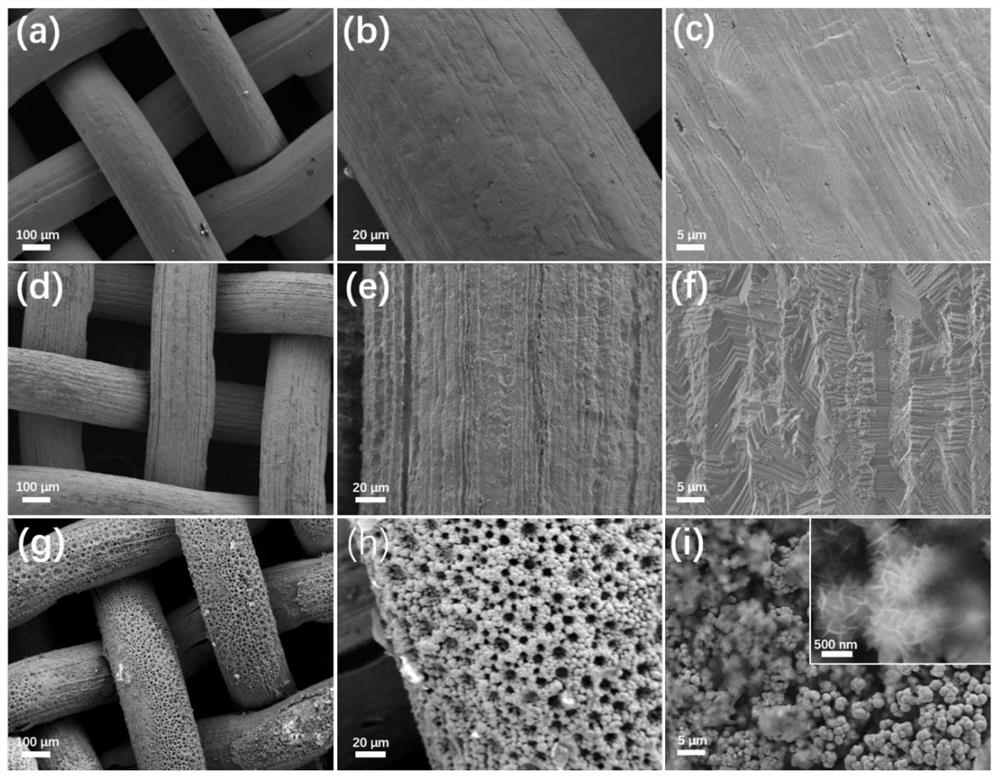

[0031] Embodiment 1: prepare the nickel mesh (E-NM) with rough surface

[0032] (1) A commercial nickel mesh (NM) with a size of 1.5 × 1 cm was ultrasonically treated in 3M HCl solution for 15 minutes to remove surface oxides and impurities, and then rinsed alternately with deionized water and ethanol several times in an ultrasonic bath. Afterwards, the nickel mesh was vacuum-dried at 60° C. and kept in a vacuum desiccator until use.

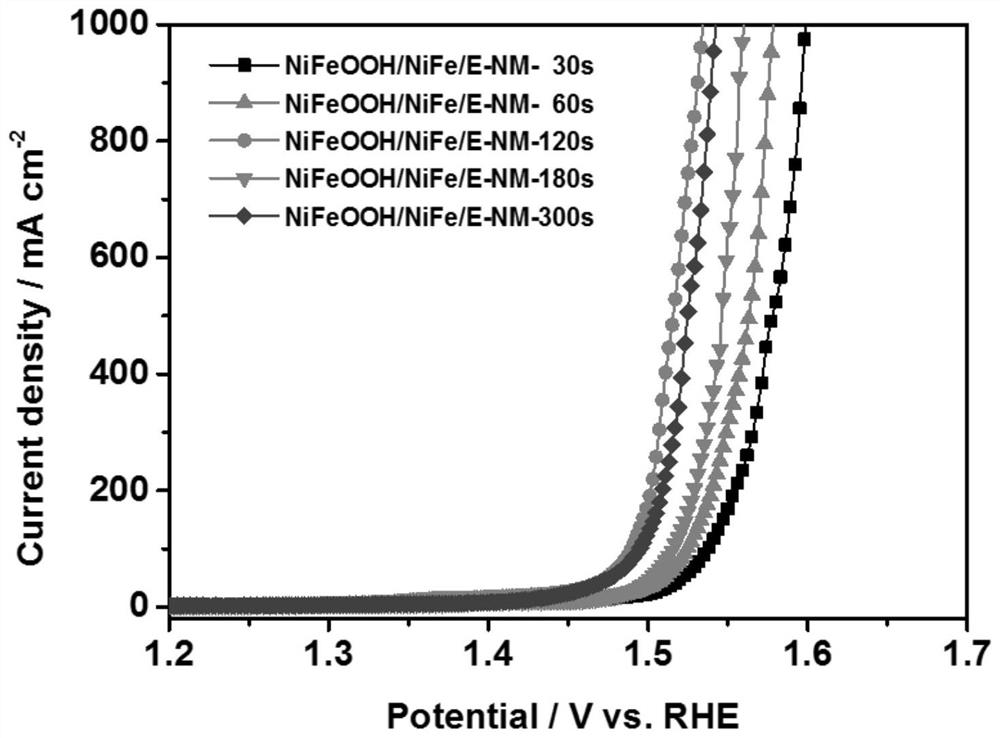

[0033] (2) 3M HCl continues to be used as the electrolyte, and a three-electrode system is used. The NM treated in step (1) is used as the working electrode, the graphite rod is used as the contrast electrode, and Ag / AgCl is used as the reference electrode. Chronoamperometry it is used for electrochemical For etching, set the voltage to 1V, and measure the performance of the E-NM electrodes obtained under different etching times. As shown in Table 1, the optimal time for electrochemical etching is 100s.

[0034] Table 1

[0035]

[0036] (3...

Embodiment 2

[0045] Embodiment 2: The preparation method of NiCoOOH / NiCo / E-NM is as follows:

[0046] (1) with 2M NH 4 Cl, 0.2M H 3 BO 3 , 0.1M NiSO 4 and 0.1M CoSO 4 The mixed solution of NiCo is used as the electrolyte for depositing NiCo, and a two-electrode system is adopted, and the E-NM-100s prepared by electrochemical etching in step (2) of Example 1 is used as the cathode. Using 500mA·cm -2 The constant current density is used for electrodeposition, the deposition time is 120s, NiCo / E-NM is obtained after washing and drying, and the mass of NiCo deposited per unit area of E-NM-100s is 9.5mg / cm 2 .

[0047] (2) Using 1M KOH solution as the electrolyte, using a three-electrode system, using NiCo / E-NM as the working electrode, graphite rod as the counter electrode, and Hg / HgO as the reference electrode, the chronopotential method CP is used for electrochemical oxidation, Set 500mAcm -2 Oxidation was performed at a constant current for 30 min, and NiCoOOH / NiCo / E-NM electrodes...

Embodiment 3

[0050] Embodiment 3: The preparation method of NiMoOOH / NiMo / E-NM is specifically as follows:

[0051] (1) with 2M NHCl 4 , 0.2M of H 3 BO 3 , 0.1M NiSO 4 and 0.1M of H 8 MON 2 o 4 The mixed solution of NiMo is used as the electrolyte for depositing NiMo, and a two-electrode system is adopted, and the E-NM-100s prepared by electrochemical etching in step (2) of Example 1 is used as the cathode. Using 500mA·cm -2 The constant current density is used for electrodeposition, and the deposition time is 120s. After washing and drying, NiMo / E-NM is obtained. The mass of NiMo deposited per unit area of E-NM-100s is 9.7mg / cm 2 .

[0052] (2) Using 1M KOH solution as the electrolyte, using a three-electrode system, using NiMo / E-NM as the working electrode, graphite rod as the counter electrode, and Hg / HgO as the reference electrode, the chronopotential method CP is used for electrooxidation. Set 500mAcm -2 Oxidation was performed at a constant current for 30 min, and the NiMo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com