A method for preparing highly active ternary metal oxide oxygen evolution catalyst by using waste ternary nickel-cobalt lithium manganese oxide

A technology of nickel cobalt lithium manganate and ternary metal, applied in the field of waste resource utilization and catalytic chemistry, can solve problems such as recycling and disposal, and achieve the effects of simple production process, controllable process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a highly active ternary metal oxide oxygen evolution catalyst by using waste ternary nickel-cobalt lithium manganese oxide is carried out in sequence according to the following steps:

[0044] (11) Sieve the ternary nickel-cobalt lithium manganate positive electrode material (containing nickel, cobalt, and manganese) in the discarded lithium-ion battery after crushing, take the under-sieve, grind the under-sieve into powder, and pass through 400 mesh Sieve, soak in 3M dilute hydrochloric acid for 10 hours, take the supernatant and record it as A;

[0045] (12) Add a certain amount of sodium hydroxide solution to A until the pH value of the solution is 7 to obtain B;

[0046] (13) Add cetyltrimethylammonium bromide 8g / L to B to obtain C;

[0047] (14) Put copper foam (thickness 0.01cm) with a diameter of 1cm×1cm into C, use copper foam as the working electrode, and use C as the reaction solution, soak the foam copper on the surface of the C soluti...

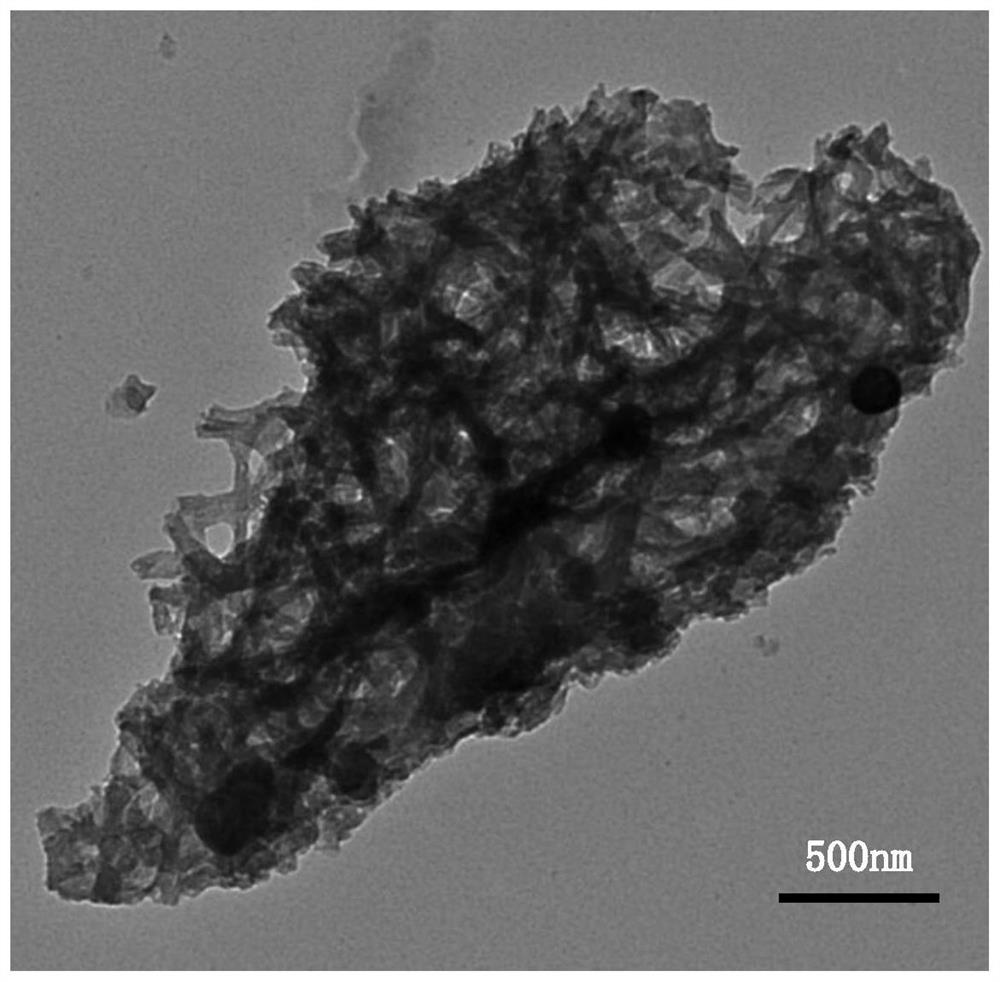

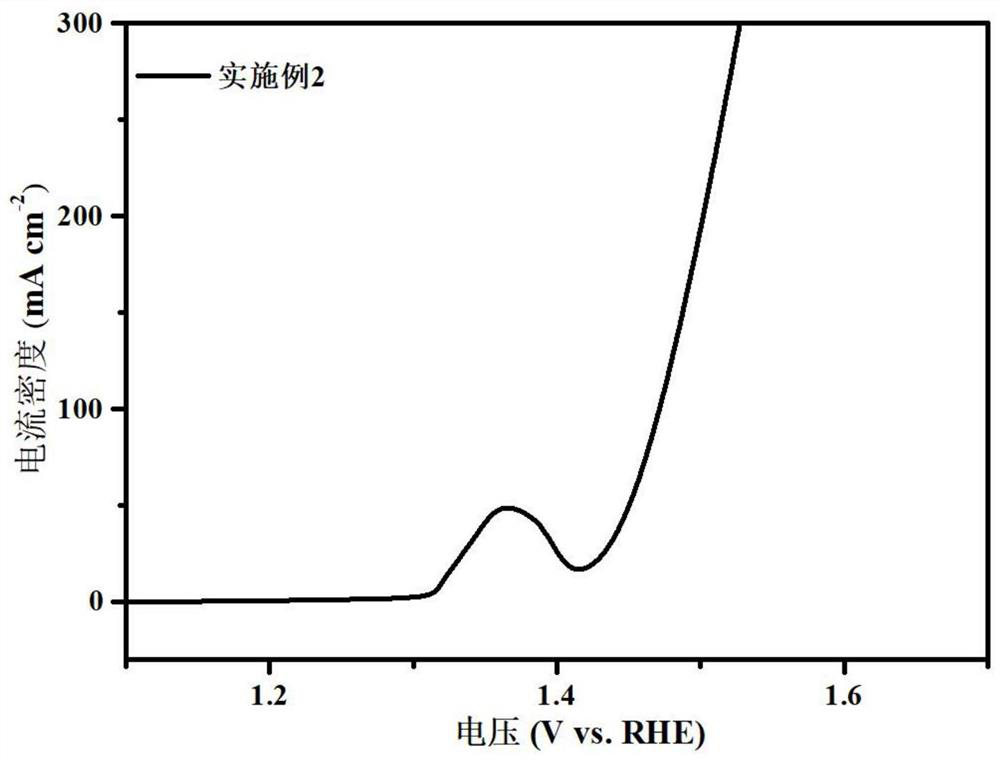

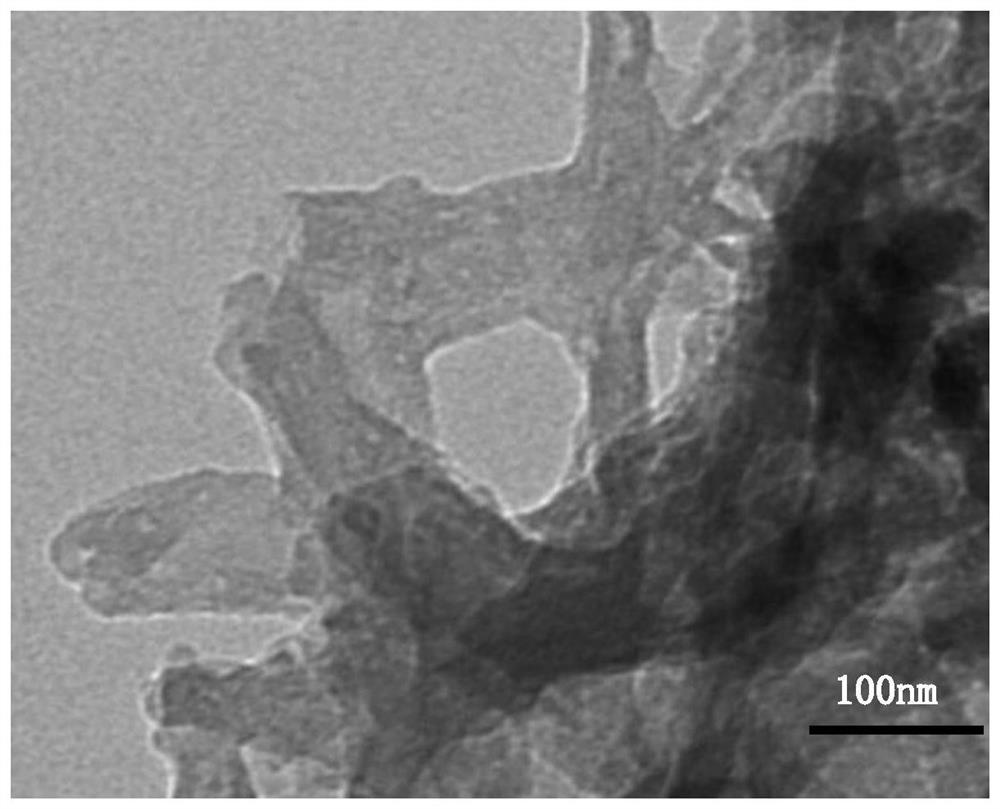

Embodiment 2

[0051] A method for preparing a highly active ternary metal oxide oxygen evolution catalyst by using waste ternary nickel-cobalt lithium manganese oxide is carried out in sequence according to the following steps:

[0052] (21) Sieve the discarded ternary nickel-cobalt lithium manganate cathode material after crushing, take the undersieve, grind the undersieve into powder, pass through a 400-mesh sieve, soak in 4M dilute hydrochloric acid for 15 hours, and take the supernatant The liquid is marked as A;

[0053] (22) Add a certain amount of sodium hydroxide solution to A until the pH value of the solution is 7 to obtain B;

[0054] (23) Add cetyltrimethylammonium bromide 16g / L to B to obtain C;

[0055] (24) Put copper foam (thickness 0.01cm) with a diameter of 1cm×1cm into C, take foam copper as the working electrode, and C as the reaction solution, soak the foam copper on the surface of the C solution, and at the same time treat the foam in an oxygen atmosphere Copper is s...

Embodiment 3

[0059] A method for preparing a highly active ternary metal oxide electrocatalyst by using waste ternary nickel-cobalt lithium manganese oxide is carried out in sequence according to the following steps:

[0060] (31) Sieve the waste ternary nickel-cobalt lithium manganate positive electrode material after crushing, take the undersieve, grind the undersieve into powder, pass through a 400-mesh sieve, soak in 6M dilute hydrochloric acid for 12 hours, and take the supernatant The liquid is marked as A;

[0061] (32) Add a certain amount of sodium hydroxide solution to A until the pH value of the solution is 7 to obtain B;

[0062] (33) Add cetyltrimethylammonium bromide 10g / L to B to obtain C;

[0063] (34) Put copper foam with a diameter of 1cm×1cm (thickness 0.01cm) into C, use copper foam as the working electrode, and use C as the reaction solution, soak the foamed copper on the surface of the C solution, and at the same time treat the foam in an oxygen atmosphere Copper is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com