Selective oxidation and flotation separation method of pyrite gangue in sulfide ore

A separation method and technology for sulfide ore, applied in the fields of iron sulfide, chemical instruments and methods, flotation, etc., can solve the problems of time-consuming cultivation, highly toxic inorganic inhibitors, etc., achieve a mild and environmentally friendly reaction process, and achieve selective separation. , Improve the effect of flotation recovery rate and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: (pyrite or galena single mineral photocatalyst screening-flotation case)

[0069] To analyze the photocatalytic performance of pyrite or galena single mineral, the specific photocatalytic reaction process is as follows:

[0070] Add 3g of pyrite / galena pure mineral (0.035-0.074mm), 10mL of water, and 1.5mol% of the specified photocatalyst (Table 1) into a 25mL flask filled with an oxygen atmosphere. The photocatalytic reaction was carried out in the medium until 3h; the solid-liquid mixture after the reaction was filtered-washed-suction filtered, and after repeated washing and suction filtration, the photocatalyst adhered to the surface of the mineral sample was washed to obtain the treated mineral sample. pH is 7.

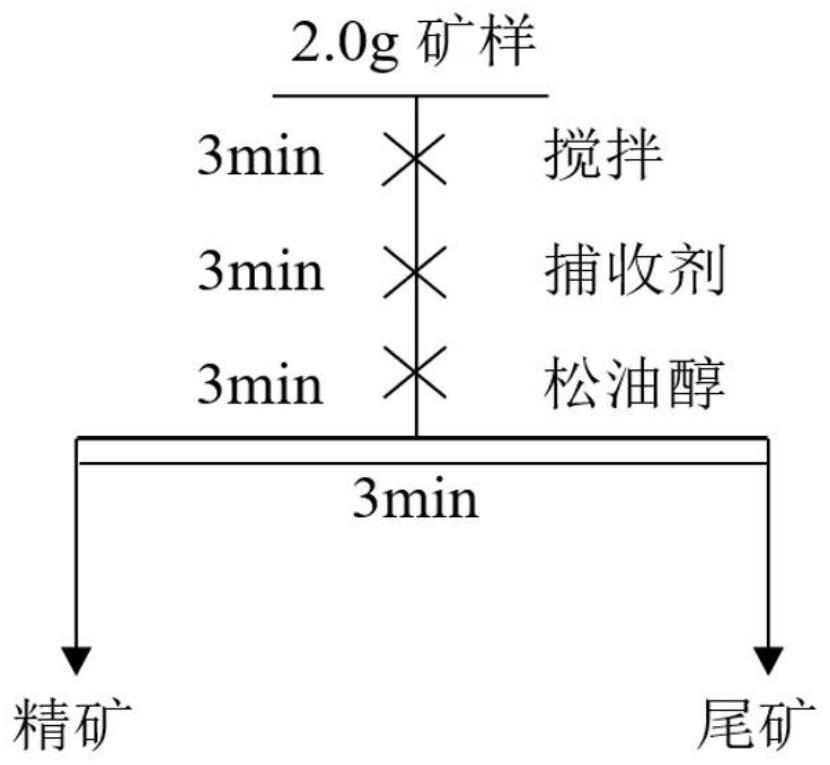

[0071] Flotation process:

[0072] Rinse the mineral sample after the photocatalytic reaction treatment into a 40mL flotation tank with water, add an appropriate amount of water, stir and inflate for 3 minutes to make it pulp, add sodium eth...

Embodiment 2

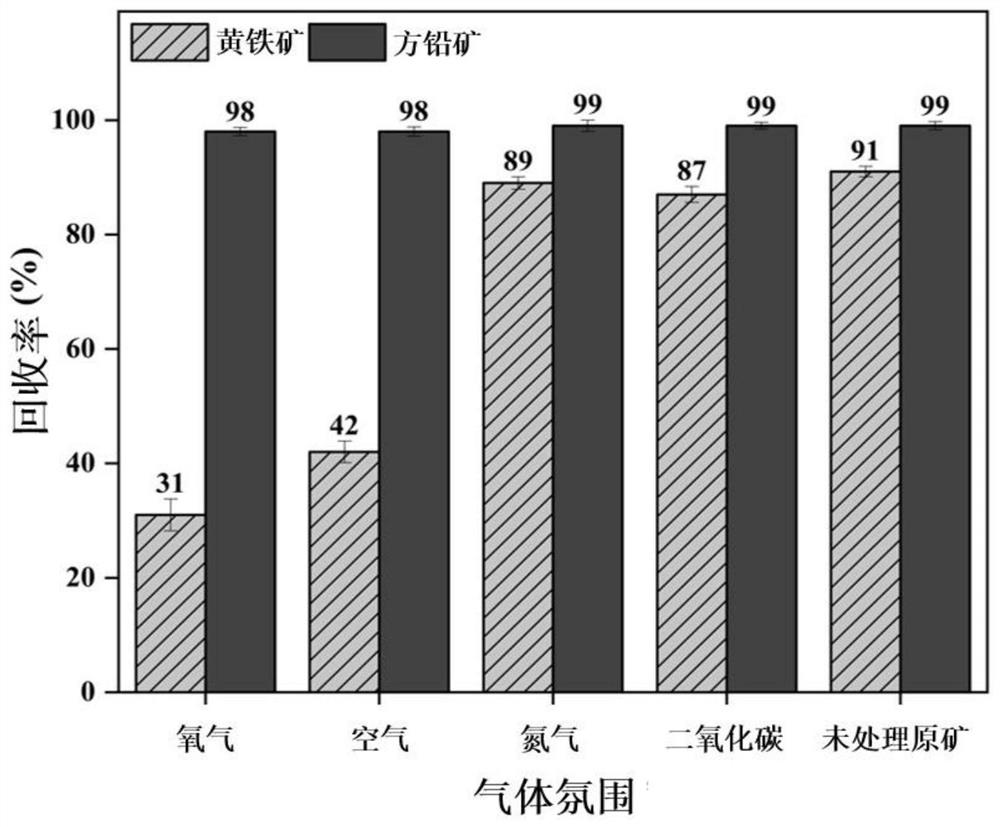

[0077] Embodiment 2: (pyrite or galena single mineral photocatalytic reaction gas atmosphere screening-flotation case)

[0078] Analyze the photocatalytic atmosphere of pyrite or galena single mineral, the specific photocatalytic reaction process:

[0079] Add 3g of pyrite / galena pure mineral (0.035-0.074mm), 10mL of water, and 1.5mol% photocatalyst (EosinY, formula 1-B) into a designated gas atmosphere (oxygen, air, nitrogen or carbon dioxide) filled In a 25mL flask, under magnetic stirring, the photocatalytic reaction was carried out in a white light LED light source device until 3h; the solid-liquid mixture after the reaction was filtered-washed-suctioned, and the light adhered to the surface of the mineral sample was removed after repeated washing and suctioned The catalyst was washed to obtain processed mineral samples, and the pH of the process was all 7.

[0080] Flotation process:

[0081]Rinse the mineral sample after the photocatalytic reaction treatment into a 40m...

Embodiment 3

[0083] Embodiment 3: (Pyrite or galena single mineral photocatalytic reaction light source screening - flotation case)

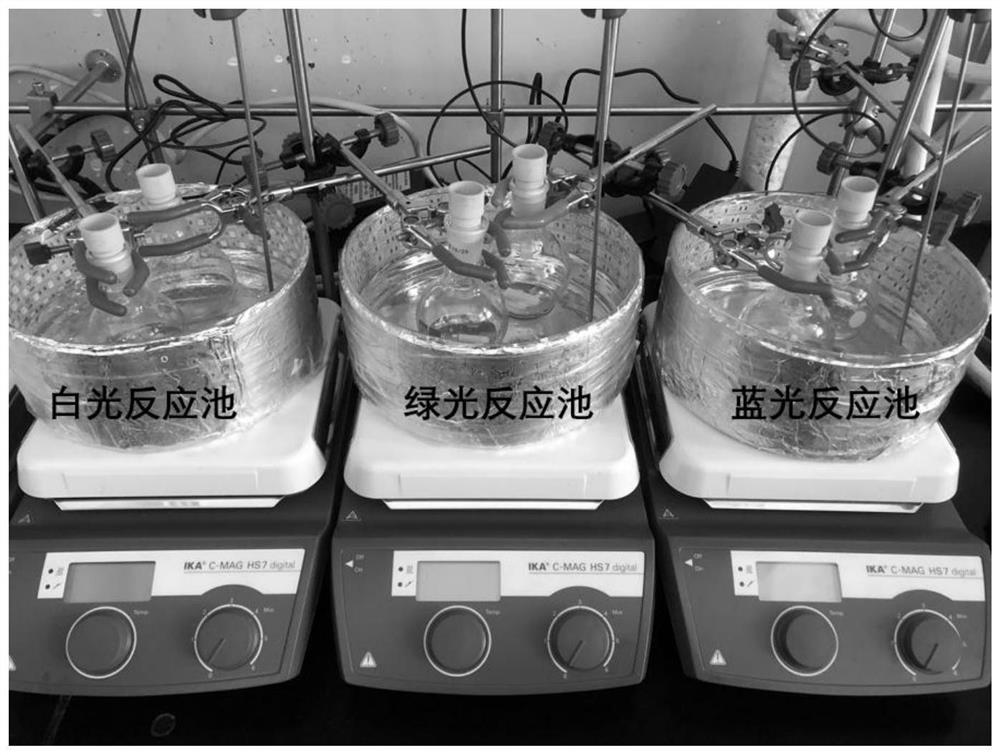

[0084] Analyze the photocatalytic light source of pyrite or galena single mineral, the specific photocatalytic reaction process:

[0085] Add 3g of pyrite / galena pure mineral (0.035-0.074mm), 10mL of water, and 1.5mol% Eosin Y into a 25mL flask filled with an oxygen atmosphere, and carry out photocatalytic reaction in a designated light source device under magnetic stirring until 3h; the reacted solid-liquid mixture is filtered-washed-suction filtered, and after repeated washing and suction filtration, the photocatalyst attached to the surface of the mineral sample is washed to obtain a treated mineral sample, and the pH of the process is 7.

[0086] Flotation process:

[0087] Rinse the mineral sample after the photocatalytic reaction treatment into a 40mL flotation tank with water, add an appropriate amount of water, stir and inflate for 3 minutes to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com