High-hardness high-modulus tantalum-hafnium-carbon ternary ceramic carbide coatings and production method thereof

A ternary ceramic and carbide technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem of difficult to achieve fine control of composition and structure, low chemical vapor deposition rate, and easy introduction of free carbon impurities and oxide impurities, to achieve the effect of good coverage and bonding, excellent physical and mechanical properties, and controllable coating composition and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

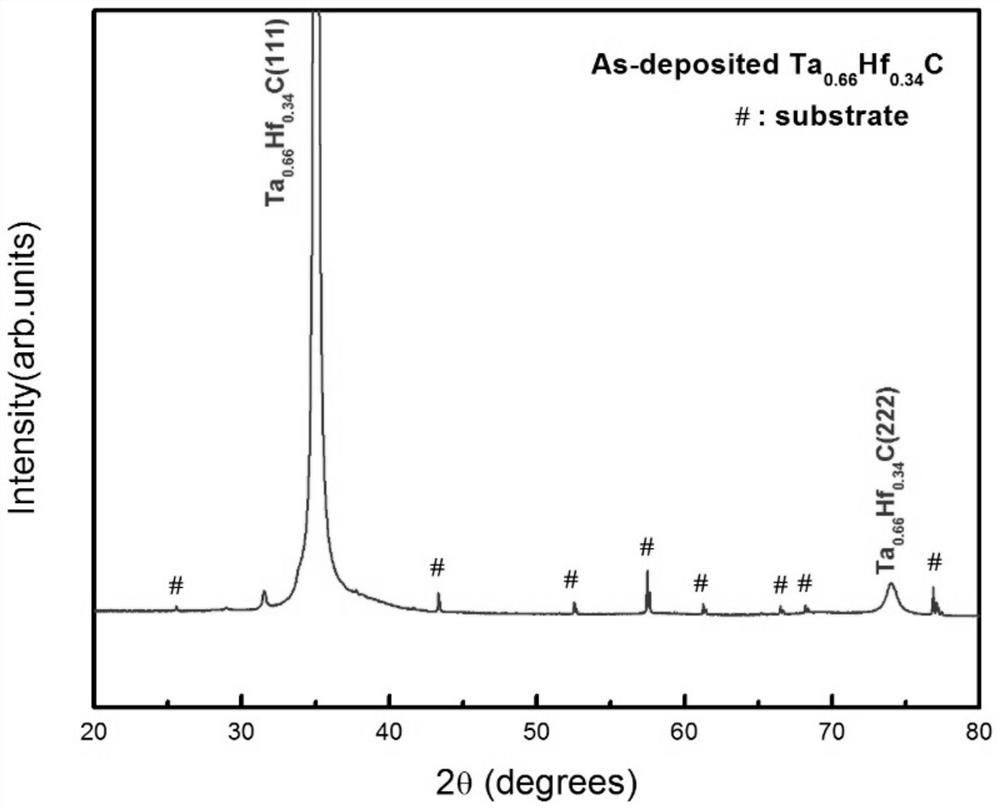

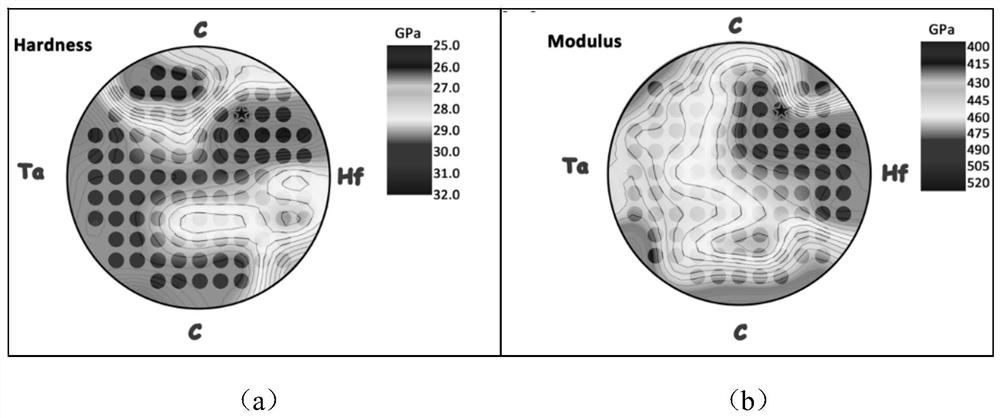

[0023] In this embodiment, the nominal composition of the tantalum-hafnium-carbon ternary ceramic carbide coating is (Ta 0.66 f 0.34 )C:

[0024] Using tantalum, hafnium and carbon three pure elements (purity 99.9%) target multi-target co-sputtering: firstly, the aluminum oxide substrate is cleaned and dried in ethanol, and placed in a vacuum chamber with a resistance heating device and a baffle On the sample stage, the vacuum degree of the background is pumped to 3×10 -5 Pa; then feed high-purity argon gas with a purity of 99.999% into the vacuum chamber to make the air pressure reach 0.4 Pa, heat the sample to 400°C and keep it for 30 minutes to make the surface temperature of the sample uniform; Apply 300 volts, 240 volts, and 400 volts of DC negative bias to the sputtering target to make the target arc. After sputtering and cleaning for 10 minutes, remove the sample stage baffle to start deposition. During the deposition process, the potential of the sample stage is grou...

Embodiment 2

[0027] In this embodiment, the nominal composition of the tantalum-hafnium-carbon ternary ceramic carbide coating is (Ta 0.5 f 0.5 )C:

[0028] Using tantalum, hafnium and carbon three pure elements (purity 99.9%) target multi-target co-sputtering: firstly, the aluminum oxide substrate is cleaned and dried in acetone, and placed in a vacuum chamber with a resistance heating device and a baffle On the sample stage, the vacuum degree of the background is pumped to 4×10 -5 Pa; then pass high-purity argon gas with a purity of 99.999% into the vacuum chamber to make the air pressure reach 0.4 Pa, heat the sample to 550°C and keep it for 30 minutes to make the surface temperature of the sample uniform; Apply 200 volts, 240 volts, and 400 volts of DC negative bias to the sputtering target to make the target arc. After sputtering and cleaning for 10 minutes, remove the sample stage baffle to start deposition. During the deposition process, the potential of the sample stage is ground...

Embodiment 3

[0031] In this embodiment, the nominal composition of the tantalum-hafnium-carbon ternary ceramic carbide coating is (Ta 0.40 f 0.60 )C:

[0032] Using tantalum, hafnium and carbon three pure elements (purity 99.9%) target multi-target co-sputtering: firstly, the aluminum oxide substrate is cleaned and dried in ethanol, and placed in a vacuum chamber with a resistance heating device and a baffle On the sample stage, the vacuum degree of the background is pumped to 5×10 -5Pa; then pass high-purity argon gas with a purity of 99.999% into the vacuum chamber to make the air pressure reach 0.4 Pa, heat the sample to 700°C and keep it for 30 minutes to make the surface temperature of the sample uniform; Apply 300 volts, 240 volts, and 400 volts of DC negative bias to the sputtering target to make the target arc. After sputtering and cleaning for 10 minutes, remove the sample stage baffle to start deposition. During the deposition process, the potential of the sample stage is groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com