Epoxy foamed structural adhesive film capable of resisting 177 DEG C thermal oxidation for 3000 hours and preparation method thereof

A technology of epoxy structural adhesives and structural adhesives, which is applied in the direction of epoxy resin adhesives, adhesives, polyether adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

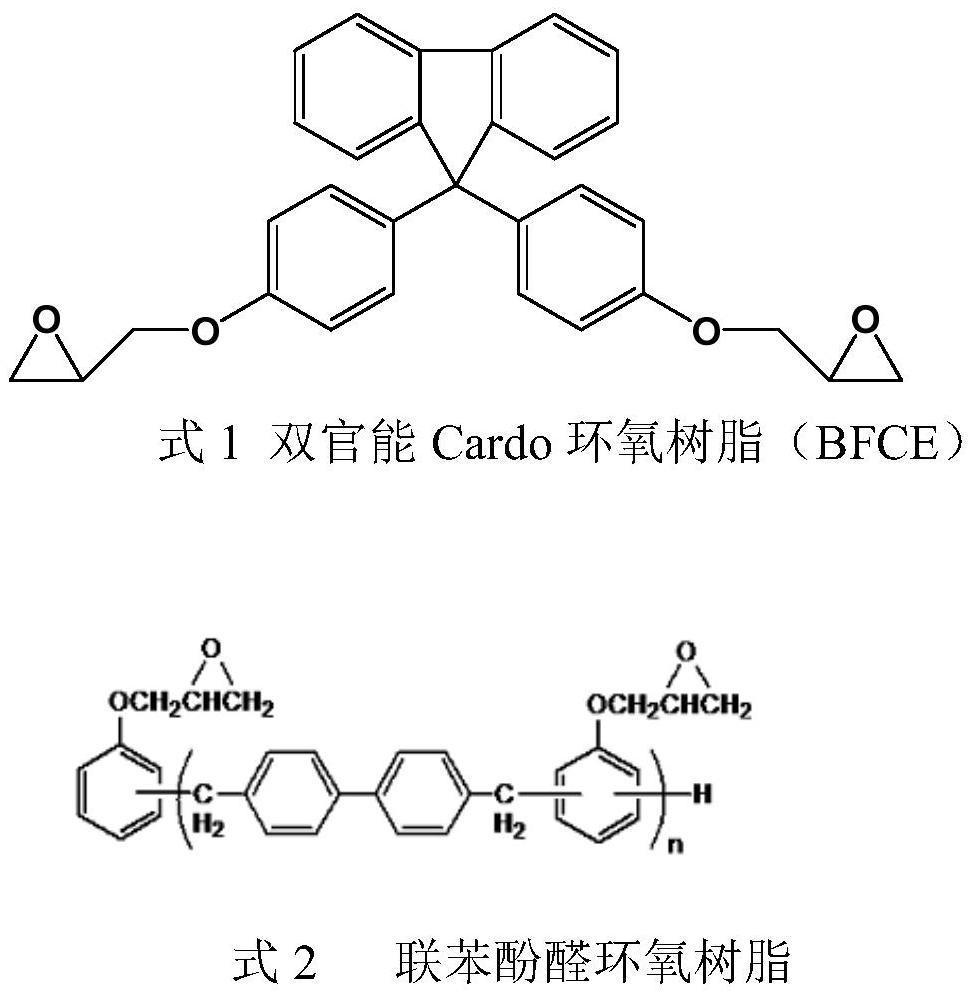

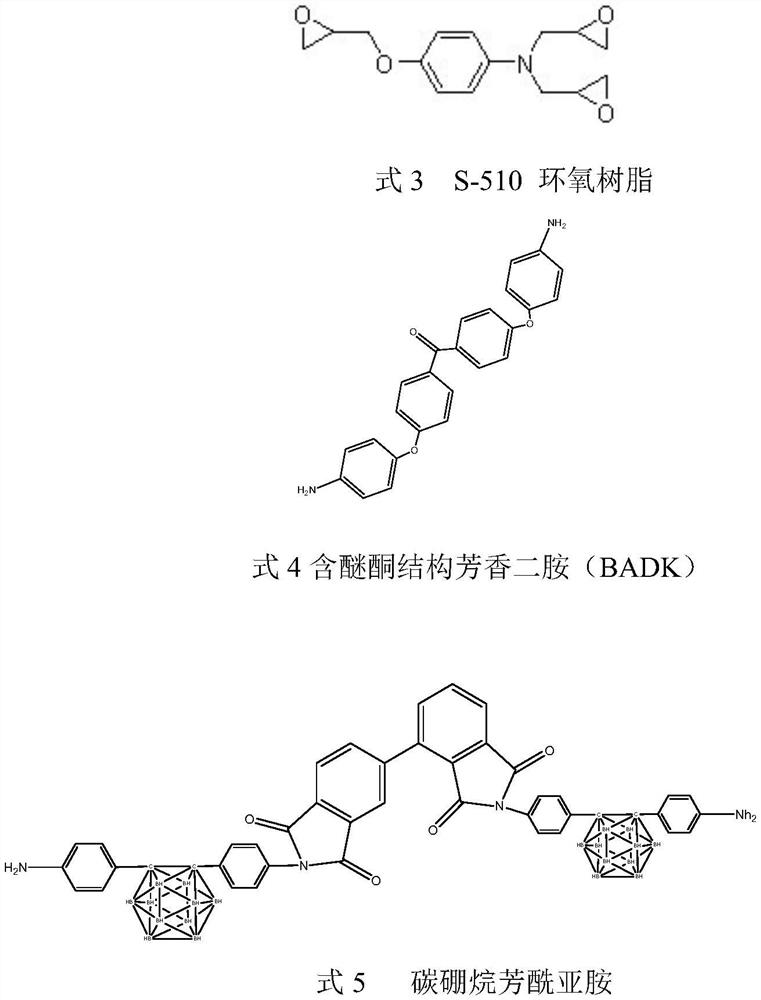

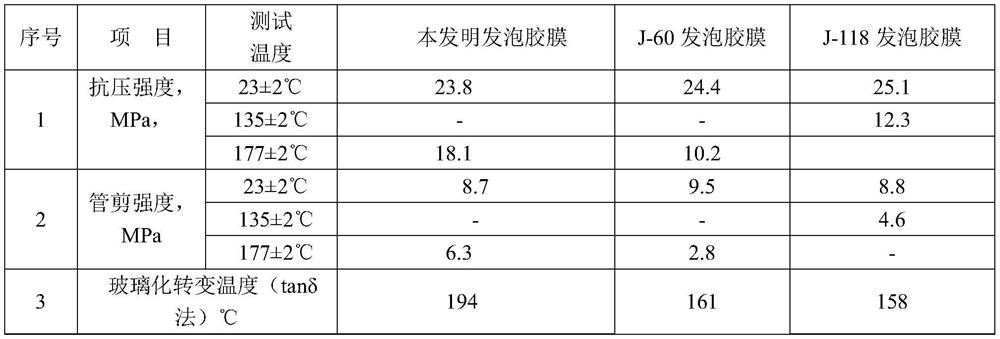

[0042] A 3000h epoxy foam film resistant to thermal oxygen at 177°C, the epoxy foam structure film consists of 75 parts of epoxy resin, 10 parts of thermoplastic resin, 2 parts of foaming agent, 7 parts The curing agent of part rubber elastomer, 4 parts of inorganic fillers, 1 part of antioxidant and 15 parts is made; The epoxy resin in the described foam film is made of bifunctional Cardo epoxy resin (BFCE), biphenol Aldehyde epoxy resin, bisphenol A epoxy resin and trifunctional epoxy resin (S-510) are composed in a weight ratio of 3:2:1:1. The curing agent in the epoxy foam structure adhesive film is composed of DDS, ether ketone structure aromatic diamine (BADK) and carborane aromatic imide in a weight ratio of 3:2:1. The thermoplastic resin in the epoxy foam structure adhesive film is polyamide-imide (PAI); the rubber elastomer in the described epoxy foam structure adhesive film is core-shell rubber particle MX-125; The inorganic filler in the epoxy foam structure adhesi...

Embodiment 2

[0045] A kind of epoxy foam adhesive film of 3000h under 177 ℃ thermal oxygen condition, described epoxy foam structure adhesive film is made of 85 parts of epoxy resin, 15 parts of thermoplastic resin, 3 parts of blowing agent, 10 parts The curing agent of part rubber elastomer, 6 parts of inorganic fillers, 2 parts of antioxidant and 20 parts is made; , bisphenol novolac epoxy resin, bisphenol A epoxy resin and trifunctional epoxy resin (S-510) in a weight ratio of 5:3:2:1, wherein the bisphenol A epoxy resin is E-20 model.

[0046] The curing agent in the described epoxy foam structure adhesive film is made up of DDS, ether ketone structure aromatic diamine (BADK) and carborane aromatic imide by weight ratio 4:3:1; The epoxy foam The thermoplastic resin in the structural adhesive film is composed of polyamide-imide (PAI), polyetherimide (PEI), polyarylether nitrile ketone (PPENK) and polyether sulfone ketone (PPESK) mixed in equal proportions; The rubber elastic body in t...

Embodiment 3

[0049] The difference between the epoxy foam structure adhesive film of this embodiment and embodiment 2 is that the epoxy foam structure adhesive film of this embodiment consists of 95 parts of epoxy resin, 20 parts of thermoplastic resin, 3 parts of foaming agent, 12 parts It is made of rubber elastomer, 8 parts of inorganic filler, 3 parts of antioxidant and 25 parts of curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com