N-substituted bis-benzimidazole-containing polyimide, polyimide film, and preparation method and application of N-substituted bis-benzimidazole-containing polyimide

A technology of benzimidazole polyimide and polyimide film, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. Imine application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention provides the preparation method of polyimide film described in above technical scheme, comprises the following steps:

[0054] (1) Under protective atmosphere, diamine monomer, dianhydride monomer and organic solvent are mixed to carry out polycondensation reaction, obtain polyamic acid solution;

[0055] (2) casting the polyamic acid solution to obtain a polyamic acid wet film;

[0056] (3) performing desolventization treatment and thermal imidization on the polyamic acid wet film in sequence to obtain the polyimide film;

[0057] The diamine monomer has a structure shown in formula XI, and the dianhydride monomer has a structure shown in formula XII:

[0058]

[0059] In the invention, under the protection atmosphere, the diamine monomer, the dianhydride monomer and the organic solvent are mixed to carry out polycondensation reaction to obtain the polyamic acid solution. In the present invention, the dianhydride monomer has the structure sho...

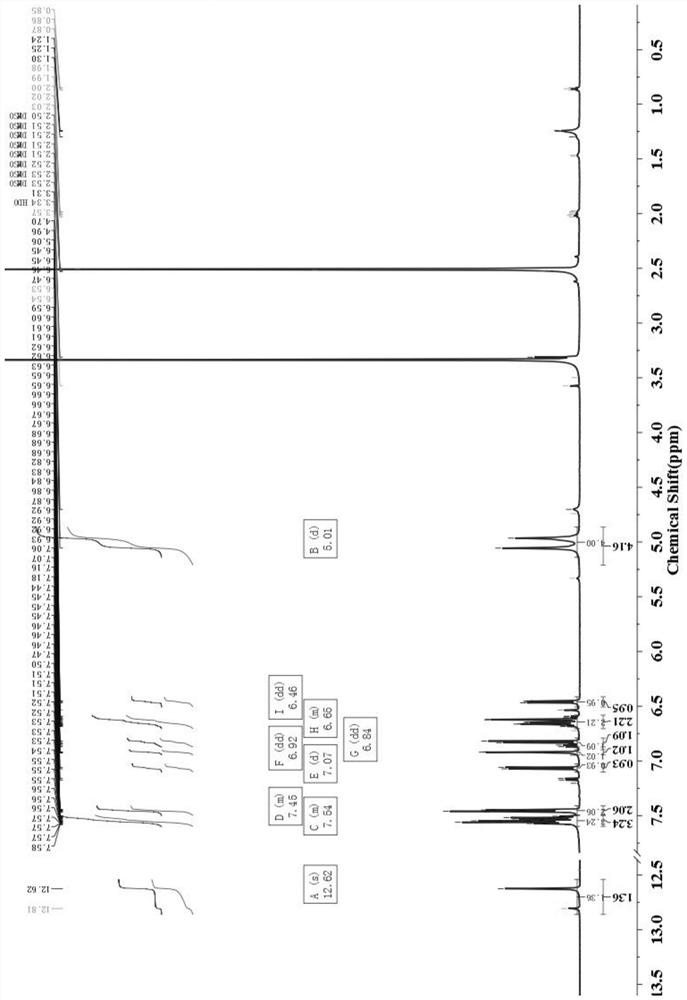

Embodiment 1

[0103] A polyimide film, the film-forming substance is an N-substituted bisbenzimidazole polyimide with a structure shown in formula II:

[0104]

[0105] The preparation method of polyimide film is as follows:

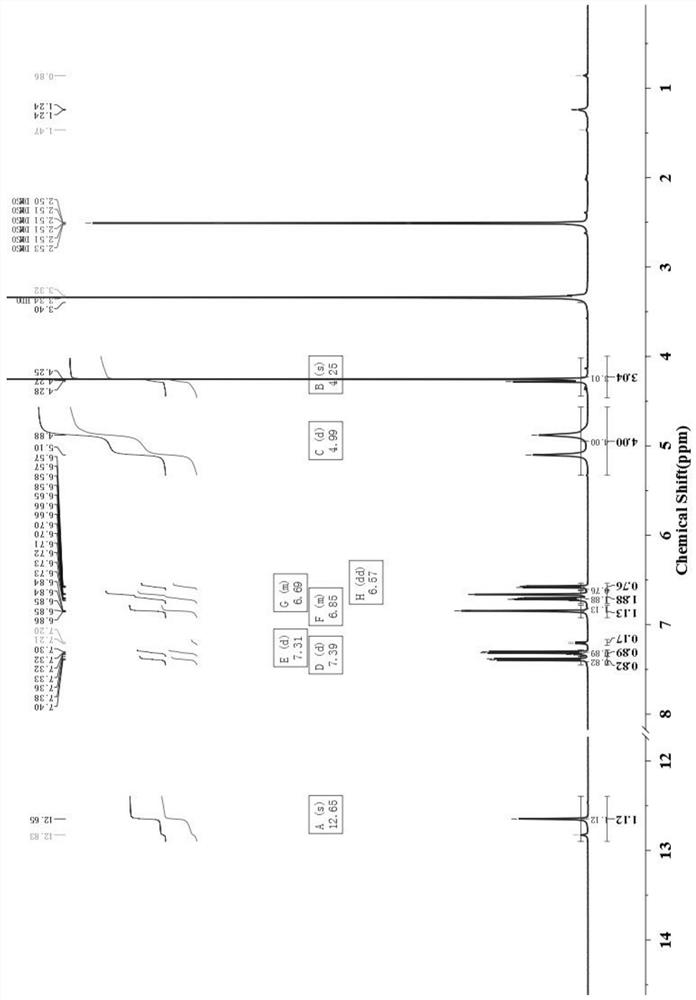

[0106] (1) Preparation of diamine monomer 1-methyl-(2,2'-bibenzimidazole)-5,5'(6')-diamine:

[0107]

[0108] The preparation method is:

[0109] Add 50.0g of 4-nitro-1,2-phenylenediamine and 500.0g of acetic acid to the reaction flask, cool down to 10±1°C, add 69.1g of methyl 2,2,2-trichloroacetimidate dropwise, The dropwise addition was completed in 0.5-1 h, and the reaction was carried out at room temperature for 12 h, and TLC confirmed that the reaction was complete. Add 1500.0g of water to the product feed liquid, filter under reduced pressure to obtain 85g of crude product, recrystallize from ethanol, filter, and dry to obtain 68.9g of 2-trichloromethyl-5(6)-nitrobenzimidazole, yield: 84.3%;

[0110] Add 65.0g 2-trichloromethyl-5(6)-nitrobenzimidazole,...

Embodiment 2

[0116] A polyimide film, the film-forming material is N-substituted bisbenzimidazole polyimide containing structure shown in formula III:

[0117]

[0118] The preparation method of polyimide film is as follows:

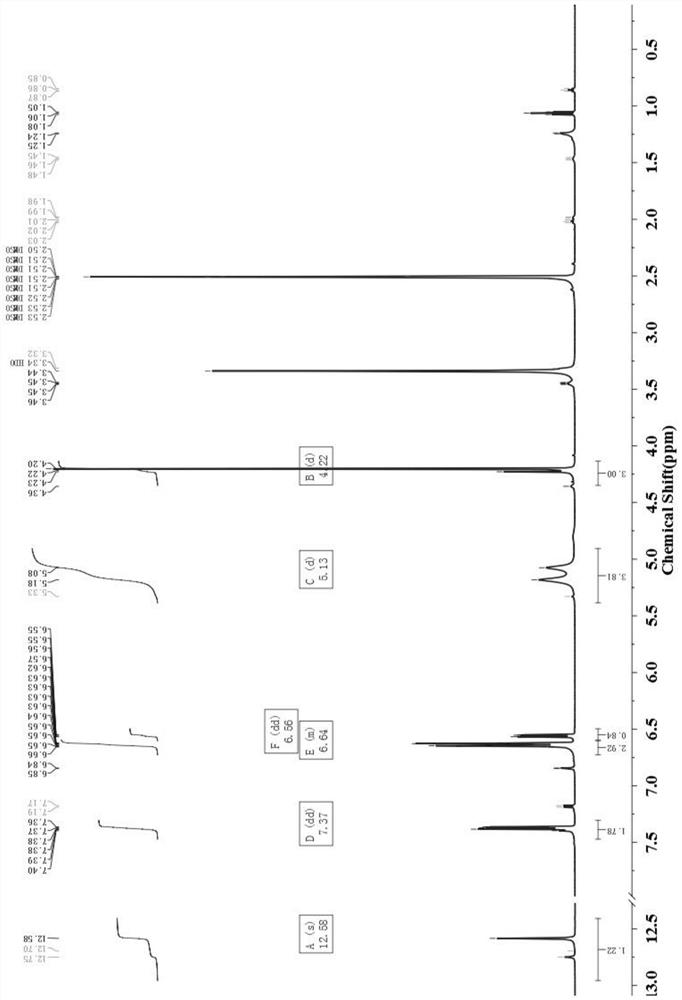

[0119] (1) Preparation of diamine monomer 1-methyl-(2,2'-bibenzimidazole)-6,5'(6')-diamine:

[0120]

[0121] The preparation method is:

[0122] Add 50.0g of 4-nitro-1,2-phenylenediamine and 500.0g of acetic acid to the reaction flask, cool down to 10±1°C, add 69.1g of methyl 2,2,2-trichloroacetimidate dropwise, The dropwise addition was completed in 0.5-1 h, and the reaction was carried out at room temperature for 12 h, and TLC confirmed that the reaction was complete. Add 1,500.0 g of water to the reaction system, filter under reduced pressure to obtain 85 g of crude product, recrystallize from ethanol, filter, and dry to obtain 68.9 g of 2-trichloromethyl-5(6)-nitrobenzimidazole, yield: 84.3 %;

[0123] Add 65.0g 2-trichloromethyl-5(6)-nitrobenzimidazol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com