Preparation method of grease microcapsule

A technology of microcapsules and oils, applied in microcapsule preparations, microsphere preparation, edible oil/fat and other directions, can solve the problems of low microcapsule embedding rate, poor high temperature resistance, easy oxidative deterioration, etc. Absorption, avoid demulsification, ensure the effect of entrapment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

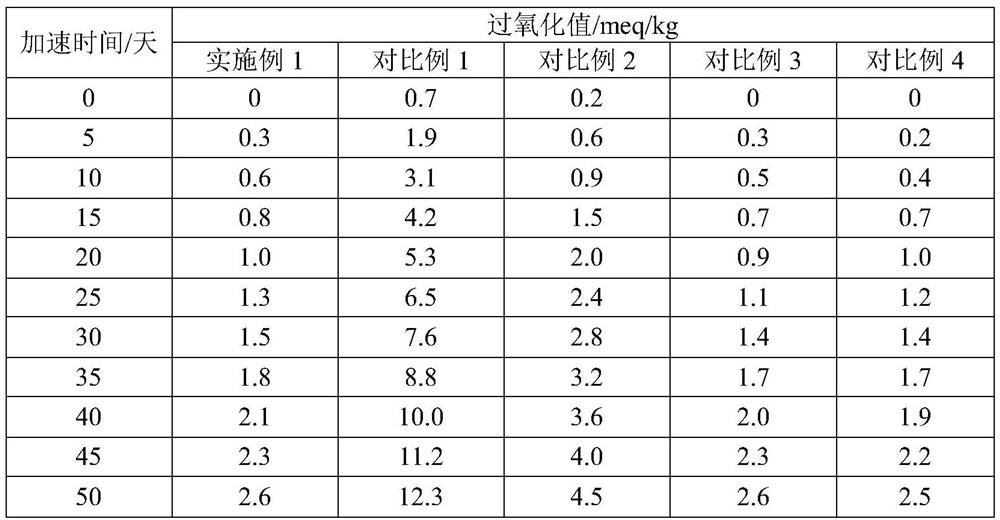

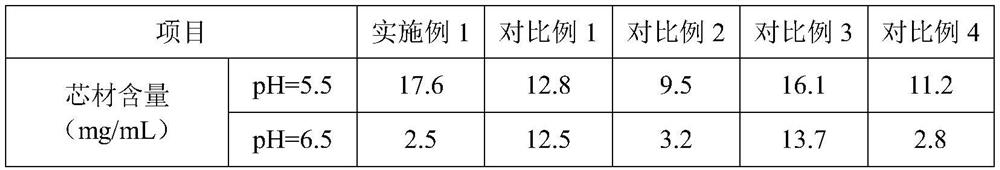

Examples

Embodiment 1

[0036]A preparation method of fish oil microcapsules, comprising the steps of:

[0037] S1: Add starch sodium octenyl succinate-N,N-dimethylaminoethyl methacrylate-chitosan copolymer, mono-diglyceride fatty acid esters and sodium ascorbate to water and mix well, adjust the pH to 5.4, cut Cut emulsification to obtain pre-emulsion; Wherein the consumption of water is 5 times of octenyl starch sodium succinate-methacrylic acid N,N-dimethylaminoethyl ester-chitosan copolymer quality, and mono-diglyceride fatty acid is in pre-emulsion The concentration in the emulsion is 1.5wt%, and the concentration of sodium ascorbate in the pre-emulsion is 3wt%;

[0038] S2: Add fish oil to the pre-emulsion as the oil core material, and then undergo shear emulsification and homogenization in turn to obtain an emulsion, in which fish oil and sodium starch octenyl succinate-N,N-dimethylaminoethyl methacrylate -The mass ratio of chitosan copolymer is 40:60;

[0039] S3: Sterilize the emulsion wit...

Embodiment 2

[0047] A preparation method of conjugated linoleic acid microcapsules, comprising the steps of:

[0048] S1: Add starch sodium octenyl succinate-N,N-dimethylaminoethyl methacrylate-chitosan copolymer, mono-diglyceride fatty acid lipids, phospholipids and vitamin E to water and mix well, adjust the pH to 5.3 , shear emulsification to obtain a pre-emulsion; wherein the amount of water is 4 times the quality of sodium starch octenyl succinate-N,N-dimethylaminoethyl methacrylate-chitosan copolymer, mono-diglyceride fatty acid The concentration in the pre-emulsion is 0.5wt%, the concentration of phospholipid in the pre-emulsion is 0.5wt%, and the concentration of vitamin E in the pre-emulsion is 2wt%;

[0049] S2: Add conjugated linoleic acid to the pre-emulsion as the oil core material, and then undergo shear emulsification and homogenization in turn to obtain an emulsion, in which conjugated linoleic acid and sodium starch octenyl succinate-methacrylic acid N , the mass ratio of...

Embodiment 3

[0058] A preparation method of soybean oil microcapsules, comprising the steps of:

[0059] S1: Add starch sodium octenyl succinate-N,N-dimethylaminoethyl methacrylate-chitosan copolymer, monoglyceride citrate and sodium ascorbate to water and mix well, adjust the pH to 5.2, cut Cut emulsification to obtain pre-emulsion; Wherein the consumption of water is 6 times of octenyl starch sodium succinate-methacrylic acid N,N-dimethylaminoethyl ester-chitosan copolymer quality, and monoglyceride citric acid is in pre-emulsion The concentration in the emulsion is 2wt%, and the concentration of sodium ascorbate in the pre-emulsion is 4wt%;

[0060] S2: Add soybean oil to the pre-emulsion as the oil core material, and then undergo shear emulsification and homogenization to obtain an emulsion, in which soybean oil and sodium starch octenyl succinate-methacrylic acid N,N-dimethylamino The mass ratio of ethyl ester-chitosan copolymer is 50:50;

[0061] S3: Sterilize the emulsion, the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com