Liquid-phase alkylation catalyst, preparation method and application thereof, and method for carrying out liquid-phase alkylation reaction on benzene and ethylene

An alkylation reaction and alkylation technology, applied in the field of liquid-phase alkylation catalysts, can solve the problems of unsuitability for the use of liquid-phase alkylation catalysts for benzene and ethylene, poor diffusion performance, insufficient external acid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

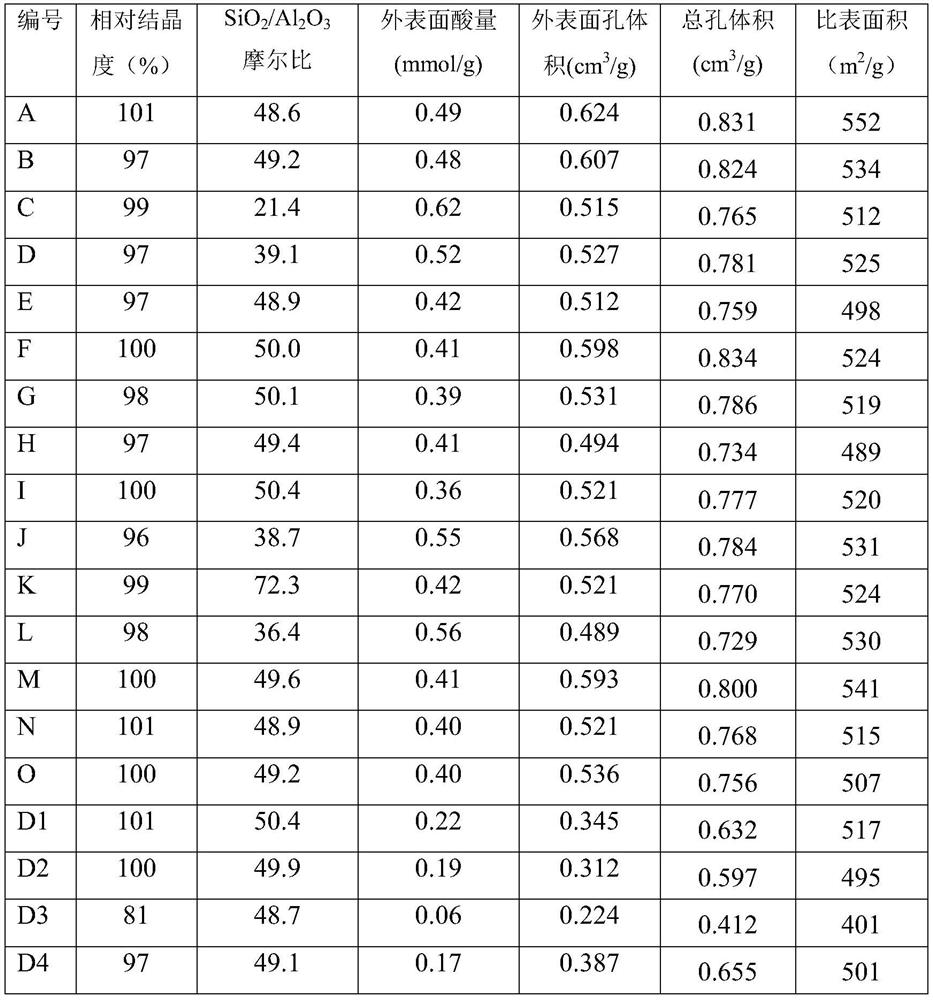

Examples

preparation example Construction

[0028] A second aspect of the present invention provides a method for preparing a liquid-phase alkylation catalyst, comprising:

[0029] (1) mixing and aging a boron source, a silicon source, an aluminum source, an alkali source, a templating agent and an aqueous solvent to obtain a gel;

[0030] (2) subjecting the gel to hydrothermal crystallization to obtain a crystallized product and mixing it with a binder to form a boron-containing MWW molecular sieve;

[0031] (3) The boron-containing MWW molecular sieve is subjected to ammonium ion exchange and roasting.

[0032] According to a preferred embodiment of the present invention, the addition of the boron source, silicon source, aluminum source, alkali source, templating agent and aqueous solvent satisfies the SiO 2 / Al 2 o 3 =10~200, B 2 o 3 / SiO 2 =0.001~0.25, OH - / SiO 2 =0.05~0.45,H 2 O / SiO 2 =5~100, template / SiO 2 =0.001~1, wherein, the boron source is represented by B 2 o 3 In terms of molar mass, the silic...

Embodiment 1

[0074] This example is used to illustrate the preparation of the liquid-phase alkylation catalyst of the present invention.

[0075] Mix 1.87g of aluminum sulfate, 2.02g of sodium hydroxide, 1.48g of sodium metaborate, 6.93g of hexamethyleneimine, 8.40g of white carbon black, and 61.64g of water under vigorous stirring, and age at 40°C After 6h, a white homogeneous gel was obtained. The gel was transferred to a stainless steel reactor lined with polytetrafluoroethylene, and crystallized at 140° C. for 5 days (days) in a stirring state, and the crystallization stirring speed was 200 r / min. After crystallization, water cooled to room temperature, washed, dried at 110°C for 4 hours, added 30% by weight of alumina binder, extruded, and calcined at 500°C for 6 hours to obtain granules. Put the above particles into 1mol / kg ammonium nitrate solution, the solid-to-liquid weight ratio (the weight ratio of boron-containing MWW molecular sieve to ammonium salt solvent) is 1:20, and exch...

Embodiment 2

[0079] This example is used to illustrate the preparation of the liquid-phase alkylation catalyst of the present invention.

[0080] Mix 1.87g of aluminum sulfate, 2.02g of sodium hydroxide, 2.96g of sodium metaborate, 6.93g of hexamethyleneimine, 8.40g of white carbon black, and 61.64g of water under vigorous stirring, and age at 40°C After 6h, a white homogeneous gel was obtained. The gel was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at 140°C for 5 days under stirring, and the crystallization stirring speed was 200r / min. After crystallization, water cooled to room temperature, washed, dried at 110°C for 4 hours, added 30% by weight of alumina binder, extruded, and calcined at 500°C for 6 hours to obtain granules. Put the above particles into 1mol / kg ammonium nitrate solution, the solid-to-liquid weight ratio is 1:20, exchange twice at 30°C for 2.5 hours each time, wash, dry at 110°C for 4 hours, and place in air at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com