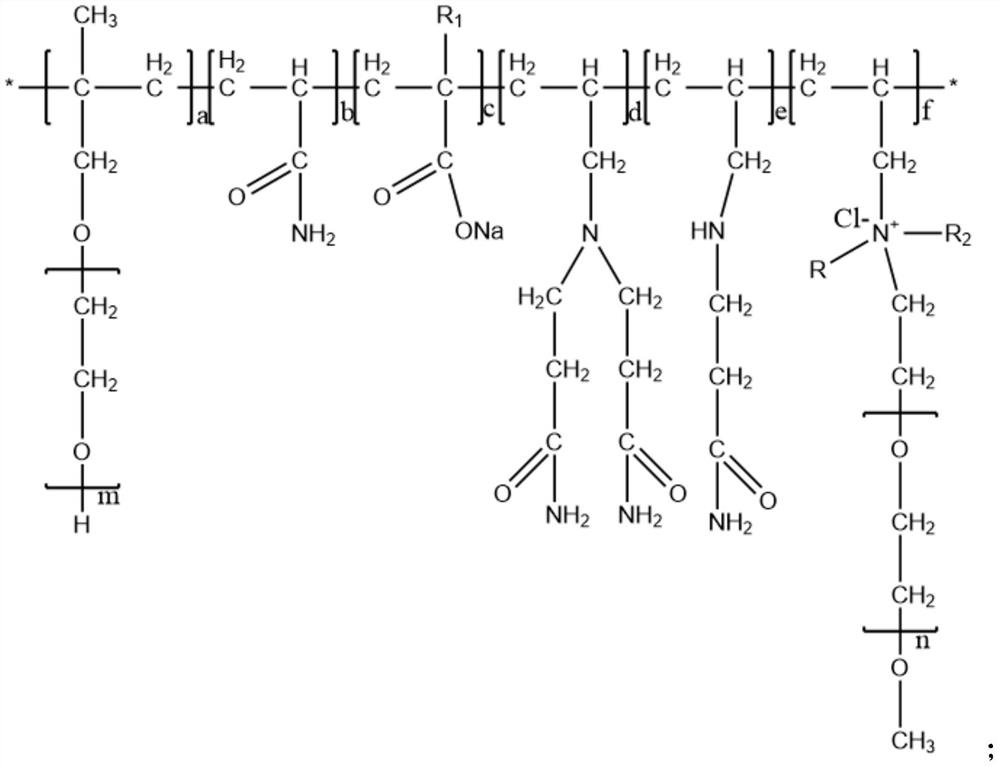

Amine ether mud-resistant super-early-strength polycarboxylate superplasticizer and preparation method thereof

A technology of strong polycarboxylic acid and mud-resistant type, which is applied in the field of concrete water reducing agent, can solve the problems of poor early strength effect and achieve the effect of increasing mud resistance, low density and high water reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

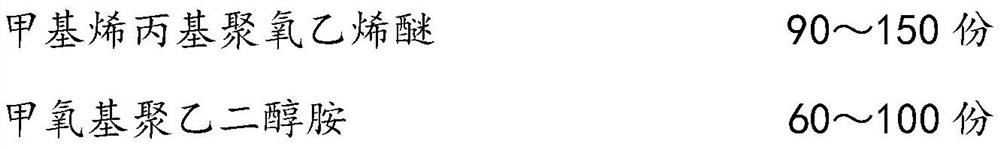

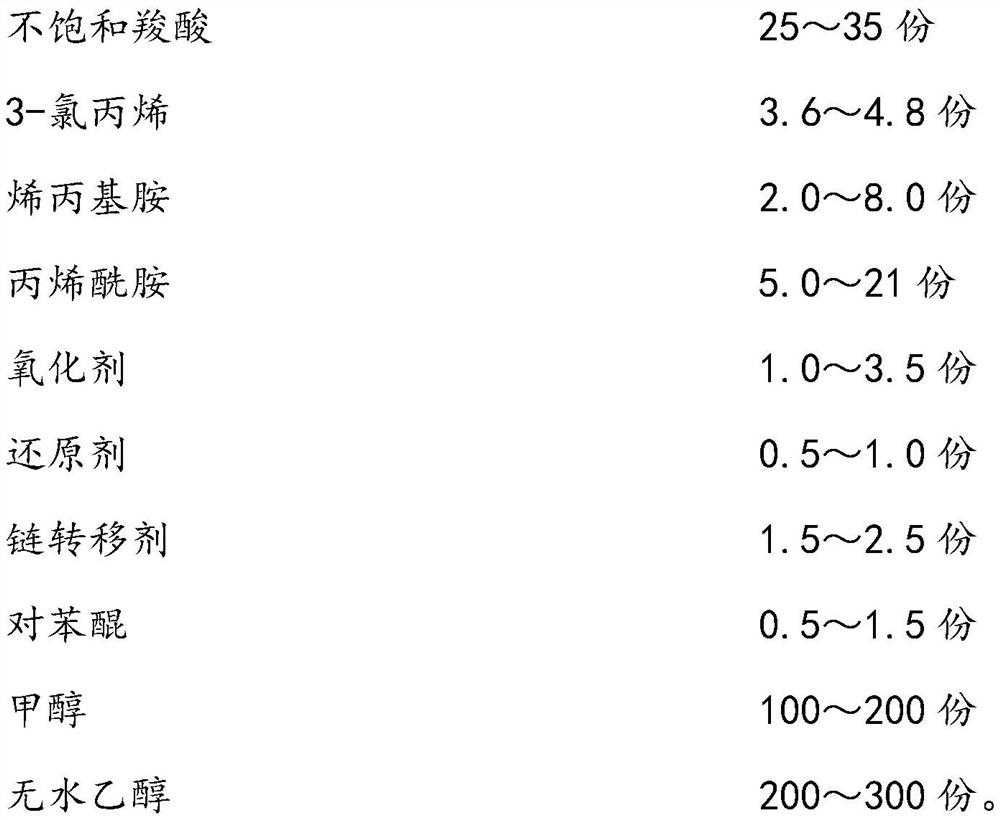

[0053](1) Weigh the raw material components as follows: Metyl propyl polyoxyethylene ether (molecular weight 4000) 114g, methoxy polyethylene glycol amine (MPEG-NH)2(Molecular weight 3500) 76g, 35g of acrylic, acrylamide 12g, allyl amine 3.3 g, 3-chloropropene 4.8 g, hydrogen-oxygen water 3.0g, sodium hydrogen phosphite, 2.0 g of sulfurgiol, phenylglycerol 1.0g , Deionized water and 32% quality concentration of liquid base.

[0054](2) 3.3 g of allyl amine is dissolved in 120 g of methanol solution, and the temperature to 10 ° C is adjusted, and 8.0 g of acrylamide is added dropwise over nitrogen gas, electromagnetic stirring is 50 h, and the reaction product is subjected to pressure reduction, and the vacuum is maintained. 0.061 MPa, distillation temperature 45 ° C, distilled to the fraction until the fraction was distilled off, and the remaining 15 g of liquid was mixed with 25 g of acrylic acid, and 50 g of deionized water was added as a solution A.

[0055](3) 76 g of methoxy polyethy...

Embodiment 2

[0060](1) Weigh the raw material components according to the weight: Metyl propyl polyoxyethylene ether (molecular weight 4000) 90 g, methoxy polyethylene glycollamine (MPEG-NH2(Molecular weight 3000) 60g, acrylic acid 8g, acrylamide 7.3 g, allyl amine 2.0 g, 3-chloropropylene, 1.0 g of ammonium sulfate, potassium sulfate, 1.8 g of sulfuric glycerol, phenylglycerol 0.5 g, deionized water and 32% quality concentration of liquid base.

[0061](2) 2.0 g of allyl allylamine is dissolved in 100 g of methanol solution, adjusted to 10 ° C, add 3.5 g of acrylamide, electromagnetic stirring at nitrogen, electromagnetic stirring for 48 h, and the reaction product is subjected to pressure reduction, and the vacuum is maintained. 0.061 MPa, distillation temperature of 45 ° C, distillation to the fraction until the fraction was distilled off, and the remaining 9.5 g of liquid was mixed with 5 g of acrylic acid, and 55 g of deionized water was added as a solution A.

[0062](3) In a stirrer, a thermome...

Embodiment 3

[0067](1) Weigh the raw material components according to the following weight: Metyl propyl polyoxyethylene ether (molecular weight 4000) 150 g, methoxy polyethylene glycollamine (MPEG-NH2(Molecular weight 5000) 100g, 35 g of methacrylic acid, 18.4 g of acrylamide, 8.0 g of allyl amine, 4.5 g of ammonium sulfate, ammonium sulfate, ammonium ammonium, 2.5g, Benzoquinone 1.5 g, deionized water and 32% mass concentration of liquid base.

[0068](2) 8.0 g of an allyl amine is dissolved in a 200 g of methanol solution, and the temperature is adjusted to 5 ° C, add 14 g of acrylamide, electromagnetic stirring at a nitrogen gas, and the reaction product is reduced and distilled, and the vacuum is 0.061. MPA, distillation temperature 45 ° C, distilled to the fraction until the fraction was distilled off, and the remaining 28 g of liquid was mixed with 20 g of methacrylic acid, and 60 g of deionized water was added as a solution A.

[0069](3) In a stirrer, a thermometer, a reflux condensate tube (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com