Energy-saving environment-friendly ammonia-process desulfurization zero-emission system and method for sulfur recovery device

An energy-saving, environmental protection, and sulfur recovery technology, which is applied in separation methods, chemical instruments and methods, and energy input, can solve problems such as waste water discharge, environmental hazards, and secondary pollution, and achieve solutions to large amounts of waste gas, improved absorption efficiency, and low investment. and the effect of land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

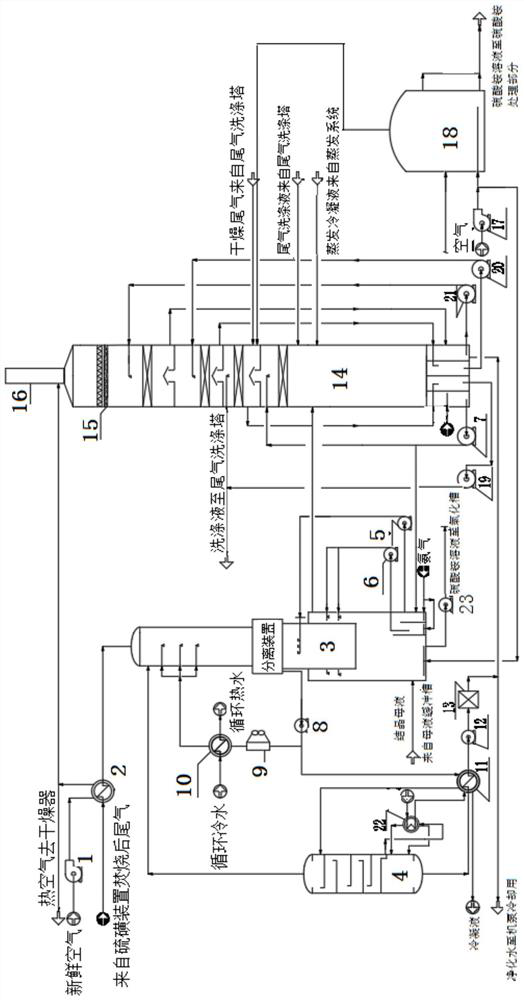

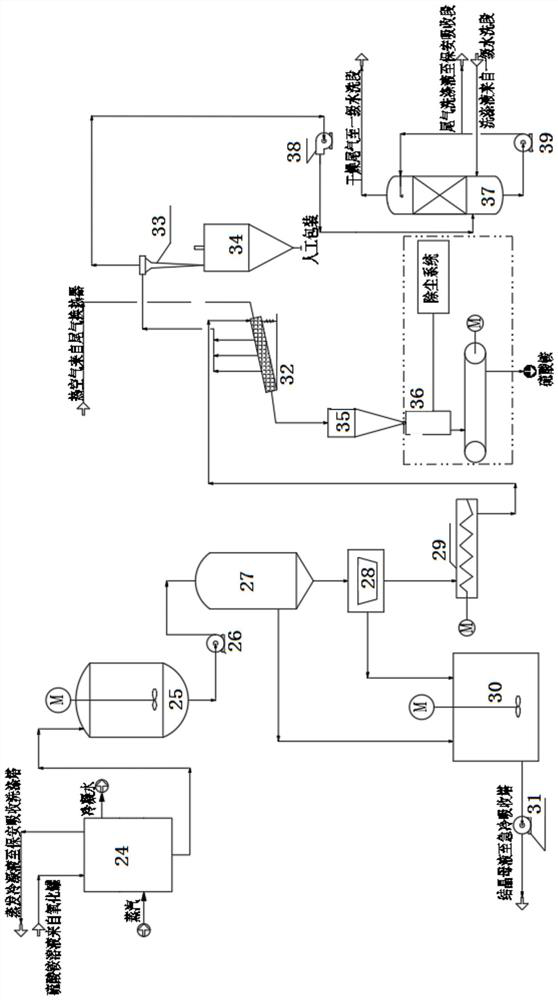

[0060] The invention is a method for tail gas treatment and ammonium sulfate treatment of a sulfur recovery device. The ammonia is used to absorb sulfur dioxide in the incineration tail gas, so that the emissions can reach the standard under various working conditions, and ammonium sulfate is produced as a by-product. This process includes rapid cooling and absorption, stripping, security absorption and washing, oxidation, evaporation, crystallization, filtration and drying. The detailed implementation is as follows:

[0061] 1. Quenching and absorption, stripping

[0062] The hot tail gas at about 300-350°C after incineration from the sulfur recovery unit, under normal working conditions, the main volume composition of the tail gas is: SO 2 0.2676%, O 2 3.00013%, CO 2 : 7.05622%, H 2 O: 15.8870%, N 2 : 73.1608%, that is, exhaust SO under normal working conditions 2 Concentration 7645mg / Nm 3 , SO under by-Pass condition 2 The concentration can be as high as 22000mg / N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com