Liquid polishing wax for stainless steel as well as preparation method and application of liquid polishing wax

A technology of stainless steel and polishing wax, which is applied in the direction of grinding/polishing equipment, polishing compositions containing abrasives, manufacturing tools, etc., and can solve problems such as harmful alkaline substances, poor compatibility of critical surface tension with the human body, and system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

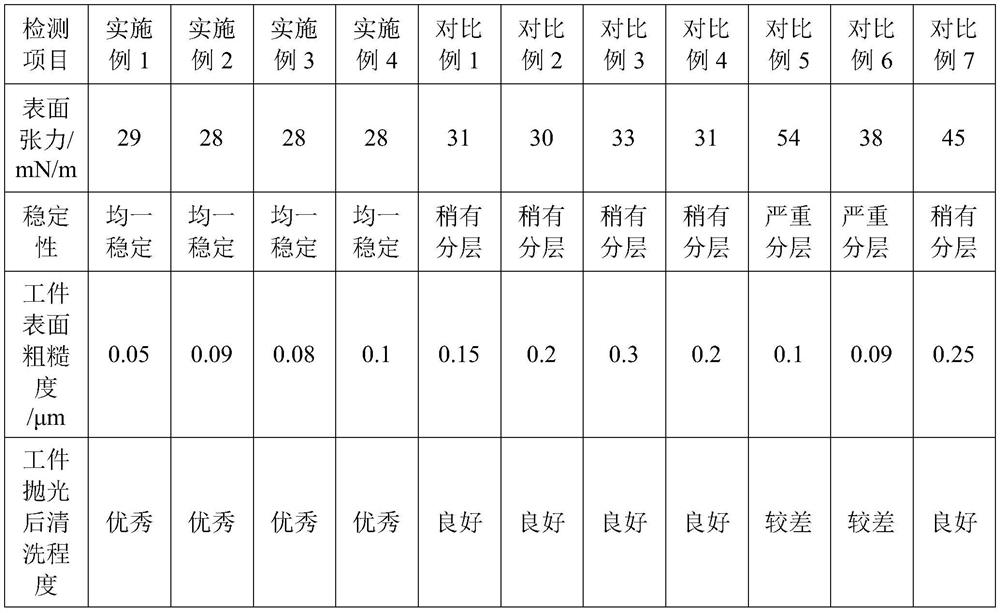

Examples

Embodiment 1

[0057] This example provides a liquid polishing wax for stainless steel, which consists of the following components in terms of mass percentage:

[0058] (1) Abrasive 20%

[0059] (2) Lubricant 23%

[0060] (3) Auxiliary 17%

[0061] (4) Water 40%.

[0062] Wherein, in terms of mass percentage, the abrasive includes 6% of α-alumina with a particle size of 200-210nm, 5% of zirconia with a particle size of 0.6-0.8μm, and 9% of cerium oxide with a particle size of 20-30nm.

[0063] In terms of mass percentage, the lubricant comprises 5% of stearic acid, 7% of oleic acid, 1% of palm wax and 10% of liquid paraffin.

[0064] In terms of mass percentage, the additives include 11% of phenylethylphenol polyoxyethylene ether, 1% of sorbitan fatty acid ester, 3% of sodium lignosulfonate, 1.5% of bentonite, and 0.5% of xanthan gum .

[0065] Above-mentioned a kind of liquid polishing wax for stainless steel, preparation method is carried out by the following steps:

[0066] (1) Add ...

Embodiment 2

[0070] This example provides a liquid polishing wax for stainless steel, which consists of the following components in terms of mass percentage:

[0071] (1) Abrasive 17%

[0072] (2) Lubricant 22%

[0073] (3) Auxiliary 15%

[0074] (4) Water 46%.

[0075] Wherein, in terms of mass percentage, the abrasive includes 4% of α-alumina with a particle size of 200-210nm, 3% of zirconia with a particle size of 0.6-0.8μm, and 10% of cerium oxide with a particle size of 20-30nm.

[0076] In terms of mass percentage, the lubricant includes 2% castor oil, 5% sulfurized fatty acid ester, 3% palm wax, 11% liquid paraffin, and 1% microcrystalline wax.

[0077] In terms of mass percentage, the auxiliary agent includes 1% sorbitan fatty acid ester, 7% fatty acid polyoxyethylene ester, 1% glyceryl monostearate, 2% polycarboxylate, alkyl naphthalene sulfonate Sodium phosphate 1%, magnesium aluminum silicate 2%, tallow amine polyoxyethylene ether 1%.

[0078] A kind of liquid polishing wax...

Embodiment 3

[0080] This example provides a liquid polishing wax for stainless steel, which consists of the following components in terms of mass percentage:

[0081] (1) Abrasive 17%

[0082] (2) Lubricant 23%

[0083] (3) Auxiliary 17%

[0084] (4) Water 43%.

[0085] Wherein, in terms of mass percentage, the abrasive includes 4% of α-alumina with a particle size of 200-210nm, 3% of zirconia with a particle size of 0.6-0.8μm, and 10% of cerium oxide with a particle size of 20-30nm.

[0086] In terms of mass percentage, the lubricant includes 2% of oleic acid, 4% of sulfurized fatty acid ester, 7% of rice bran wax and 10% of liquid paraffin.

[0087] In terms of mass percentage, the auxiliary agent includes 9% of fatty alcohol block polyether, 1% of sorbitan fatty acid ester, 1% of glyceryl monostearate, 2% of polycarboxylate, alkyl naphthalene Sodium sulfonate 1%, starch 2%, xanthan gum 1%.

[0088] A kind of liquid polishing wax for stainless steel described above, the preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com