Efficient wet rice flour cake production pre-processing equipment

A technology for processing equipment and wet powder, which is applied in the field of high-efficiency wet powder rice cake production front-end processing equipment, can solve the problems of nutrient loss, waste water discharge and environmental pollution, etc., to improve the production environment, reduce labor, and reduce process time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation process of the coating matrix is:

[0046] (1) Dissolve ethylene glycol monoethyl ether, butyl methacrylate, and N-methylol acrylamide in a reaction vessel under magnetic stirring, then add titanium tetra-n-butoxide and dodecyl hydroxypropyl sulfonate base betaine, the temperature is controlled at 60-70°C, and the reaction is 0.5-1h to obtain butyl methacrylate-N-methylolacrylamide seed liquid; the ethylene glycol monoethyl ether, butyl methacrylate, N- The ratio of methylol acrylamide, titanium tetra-n-butoxide and dodecyl hydroxypropyl sultaine is 150-200ml: 1-1.2mol: 1mol: 25-30g: 35-45g;

[0047] (2) Add vinyl benzoate to the above seed liquid, slowly heat up to 90-100°C and react for 1.5-1.8h to obtain a translucent viscous liquid. When the temperature of the liquid drops to room temperature, adjust the pH value to neutral; benzoic acid The mass ratio of vinyl ester to butyl methacrylate-N-methylolacrylamide seed solution is 1:4-6;

[0048] (3) Ad...

Embodiment 1

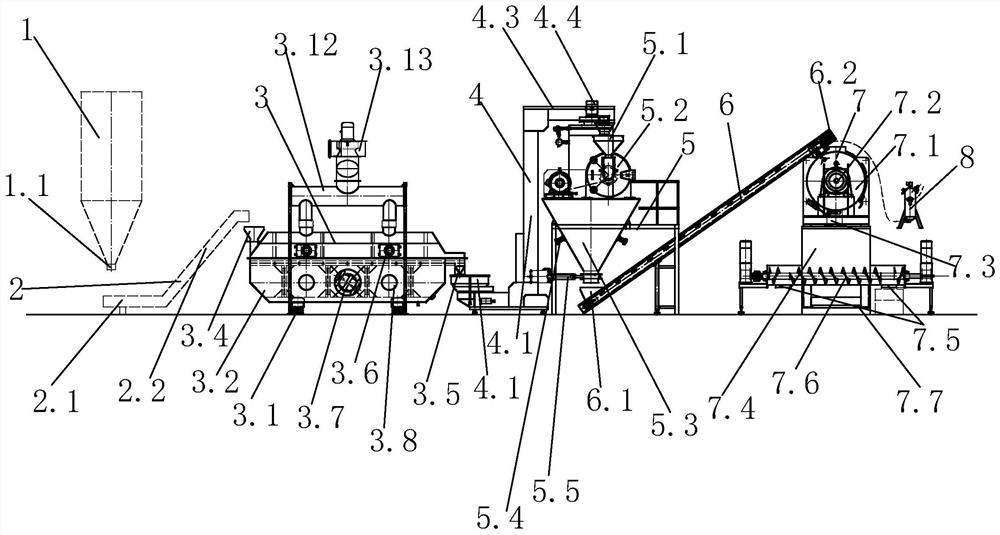

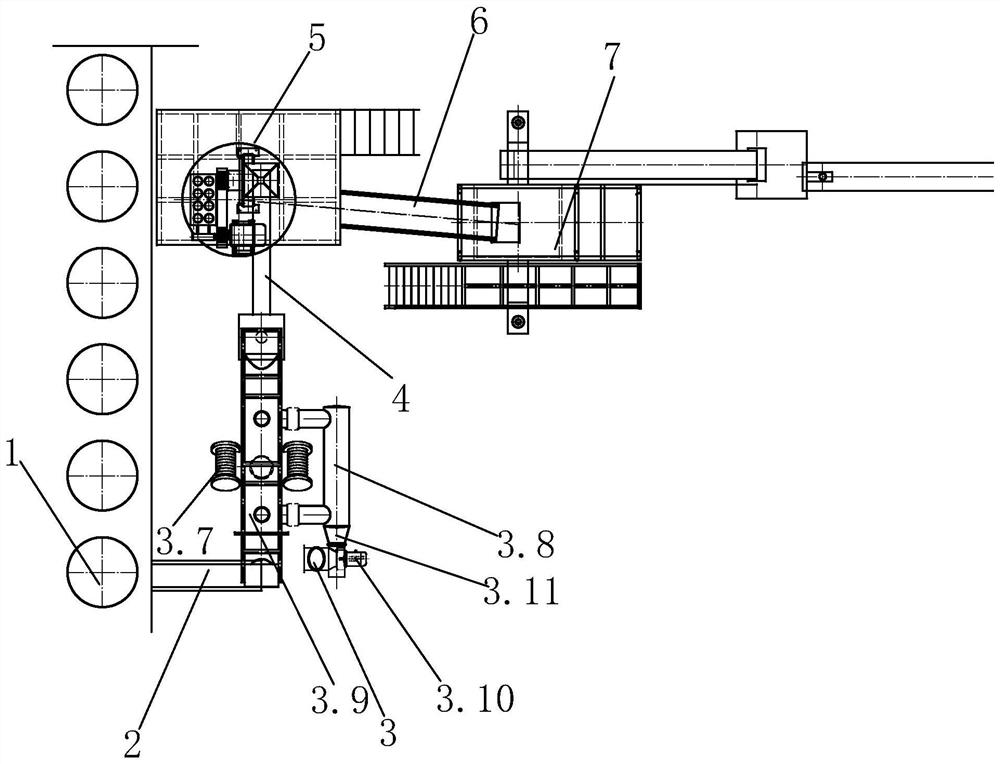

[0055] An efficient pre-processing equipment for the production of wet rice cakes, including a rice soaking bucket 1, a wet rice conveyor belt 2 located below the soaking rice bucket 1, and a vibrating water filter air dryer 3 and a bucket elevator 4 arranged in sequence , pulverizing device 5, belt conveyor 6 and weighing coulter type mixer 7, described wet rice conveyer belt 2 communicates bubble rice bucket 1 and vibrating water filter air dryer 3, and described weighing coulter type mixer 7 is provided with There are rice noodles outlet 7.5.

[0056] The bottom end of the soaking rice barrel 1 is provided with a funnel rice outlet 1.1, and the wet rice conveyor belt 2 includes a rice receiving section 2.1 and an inclined rice delivery section 2.2, the rice receiving section 2.1 is located below the funnel rice outlet 1.1, The rice receiving section 2.1 is placed in parallel, the rice sending section 2.2 is placed obliquely, and the inclined height of the rice sending secti...

Embodiment 2

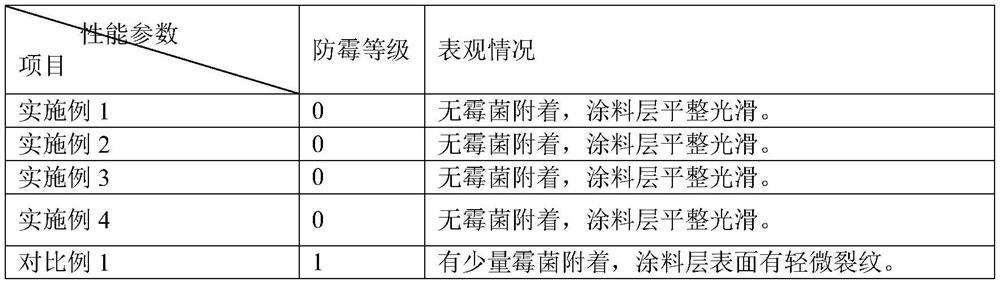

[0066] The difference from Example 1 is that the inner surface of the vibrating water filter air dryer 3 is coated with anti-mildew and anti-shock paint. The preparation process of the anti-mildew and anti-shock paint: put 50 parts of the paint matrix into the reaction container, add 40 parts of ethanol and stir; then dissolve 6 parts of slow-release agent in water and add 8 parts of chitosan solution to obtain the mixture; Adding 3 parts of diacetone alcohol to the reaction vessel and then stirring; adding the mixture dropwise to the reaction vessel and stirring for 1 h;

[0067] The preparation process of the coating matrix is:

[0068] (1) Dissolve ethylene glycol monoethyl ether, butyl methacrylate, and N-methylol acrylamide in a reaction vessel under magnetic stirring, then add titanium tetra-n-butoxide and dodecyl hydroxypropyl sulfonate base betaine, the temperature was controlled at 60°C, and the reaction was carried out for 1 h to obtain butyl methacrylate-N-methylol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com