Textile pretreatment special wastewater regeneration recycling system

A technology for textiles and waste water, which is applied in the direction of textile industry waste water treatment, filtration treatment, special treatment goals, etc. It can solve problems such as long-term recycling, waste of waste water heat, and oxidative damage to cloth surfaces, so as to achieve sustainable development and save energy. The effect of water cost and low water hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

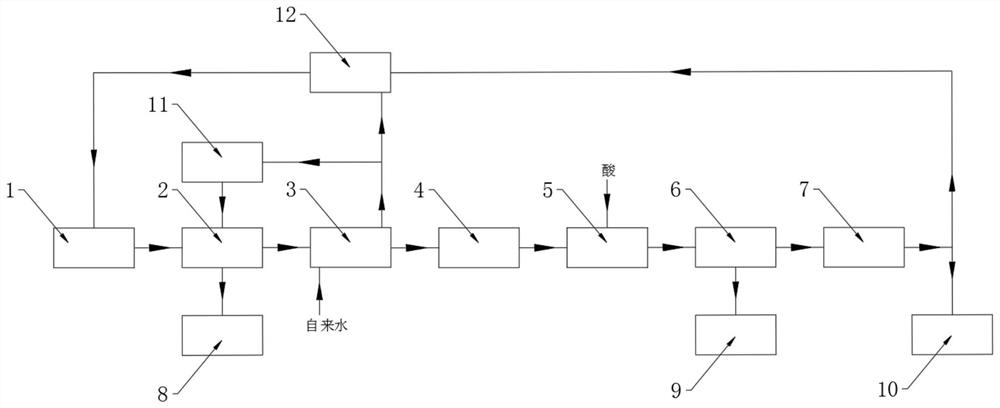

[0028] A textile pretreatment special waste water recycling system, such as figure 1 As shown, the pretreatment device 1 is included, and the pretreatment device 1 is sequentially connected with a first solid-liquid separator 2 , a heat exchanger 3 , a cooler 4 , an acid titration tank 5 and a second solid-liquid separator 6 . Specifically, the pretreatment device 1 is a steaming device or a cooking device, the steaming device is a steamer, and the cooking device is a cooking machine. The first solid-liquid separator 2 is a drum filter, and a brush roller is arranged inside the first solid-liquid separator 2 . The second solid-liquid separator 6 is a drum filter, and a brush roller is arranged in the second solid-liquid separator 6 . Drum filter, low cost, easy to operate, more ideal for collecting fibers falling off in water, and convenient for fiber recovery. The setting of the brush roller is convenient for filtering and collecting the fibers. The setting of the first so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com