White butyl self-adhesive ethylene propylene diene monomer waterproof roll and production method thereof

A technology of EPDM rubber and waterproof membrane, which is applied in adhesives, roof insulation materials, and other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

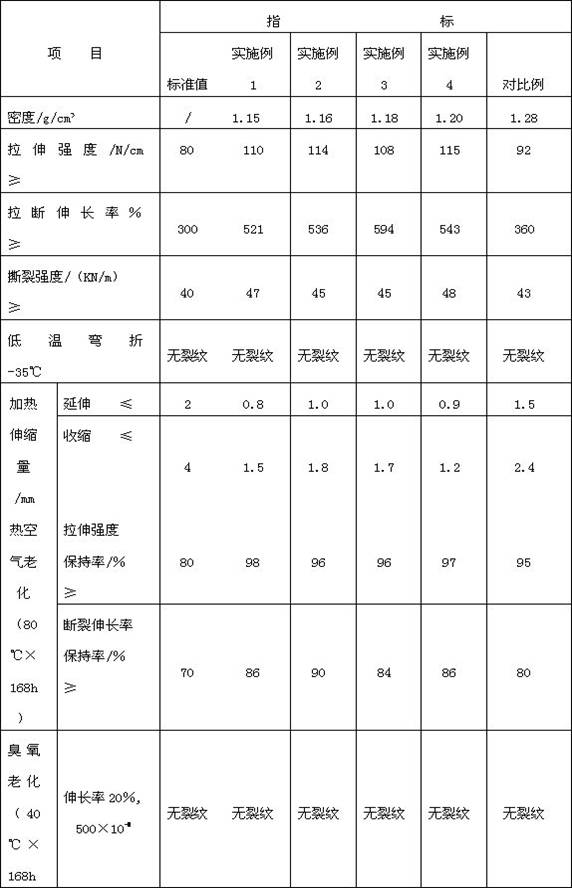

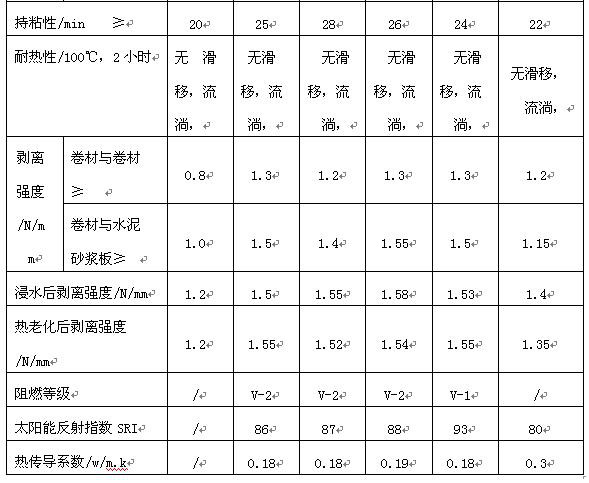

Examples

Embodiment 1

[0039] This white butyl self-adhesive EPDM composite waterproof membrane is composed of base layer, surface layer and anti-adhesive isolation layer. The base layer is EPDM waterproof layer, and the surface layer is butyl rubber self-adhesive. Layer, anti-adhesive isolation layer is PE anti-adhesive isolation film.

[0040] The ratio of each component of the base rubber, in parts by weight, is based on 100 parts of EPDM rubber, and other auxiliary materials include 50 parts of precipitated silica; 30 parts of low melting point glass powder; 40 parts of expanded perlite powder 10 parts of rutile titanium dioxide; 60 parts of plasticizer; 1 part of polyethylene glycol; 0.8 part of coupling agent; 0.4 part of antioxidant 1010; 0.4 part of sulfur; 0.5 part of triallylisocyanurate Parts; 5 parts of 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane. Wherein accelerator is sulfur and triallyl isocyanurate, and the effect that sulfur plays in the peroxide vulcanization system of th...

Embodiment 2

[0061] This white butyl self-adhesive EPDM composite waterproof membrane is composed of base layer, surface layer and anti-adhesive isolation layer. The base layer is EPDM waterproof layer, and the surface layer is butyl rubber self-adhesive. Layer, anti-adhesive isolation layer is PE anti-adhesive isolation film.

[0062] The proportion of each component of the base rubber is calculated in parts by weight, based on 100 parts of EPDM rubber, and other auxiliary materials include 60 parts of precipitated silica; 40 parts of low melting point glass powder; 50 parts of expanded perlite powder 15 parts of rutile titanium dioxide; 65 parts of plasticizer; 1 part of polyethylene glycol; 0.7 part of coupling agent; 0.4 part of antioxidant 1010; 0.4 part of sulfur; 0.6 part of triallyl isocyanurate ; 5 parts of 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane.

[0063] The proportioning of each component of surface layer rubber is identical with embodiment 1;

[0064] The produc...

Embodiment 3

[0066] This white butyl self-adhesive EPDM composite waterproof membrane is composed of base layer, surface layer and anti-adhesive isolation layer. The base layer is EPDM waterproof layer, and the surface layer is butyl rubber self-adhesive. Layer, the anti-adhesive isolation layer is PE anti-adhesive isolation film;

[0067] The ratio of each component of the base rubber, in parts by weight, is based on 100 parts of EPDM rubber, and other auxiliary materials include 65 parts of precipitated silica; 45 parts of low melting point glass powder; 55 parts of expanded perlite powder ; 20 parts of rutile titanium dioxide; 70 parts of plasticizer; 1.2 parts of polyethylene glycol; 0.8 part of coupling agent; 0.5 part of antioxidant 1010; 0.5 part of sulfur; ; 6 parts of 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane.

[0068] The proportioning of each component of surface layer rubber is identical with embodiment 1;

[0069] The production process steps of this embodiment ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com