Waterproof material for metal roof and preparation method of waterproof material

A waterproof material and metal roofing technology, applied in anti-fouling/underwater coatings, reflection/signal coatings, coatings, etc., can solve the problems that the mechanical properties of the coating film need to be improved, the waterproof coating film is prone to aging and cracking, and affects the protection effect, etc. , to achieve the effect of excellent anti-ultraviolet performance, excellent outdoor anti-aging, excellent acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

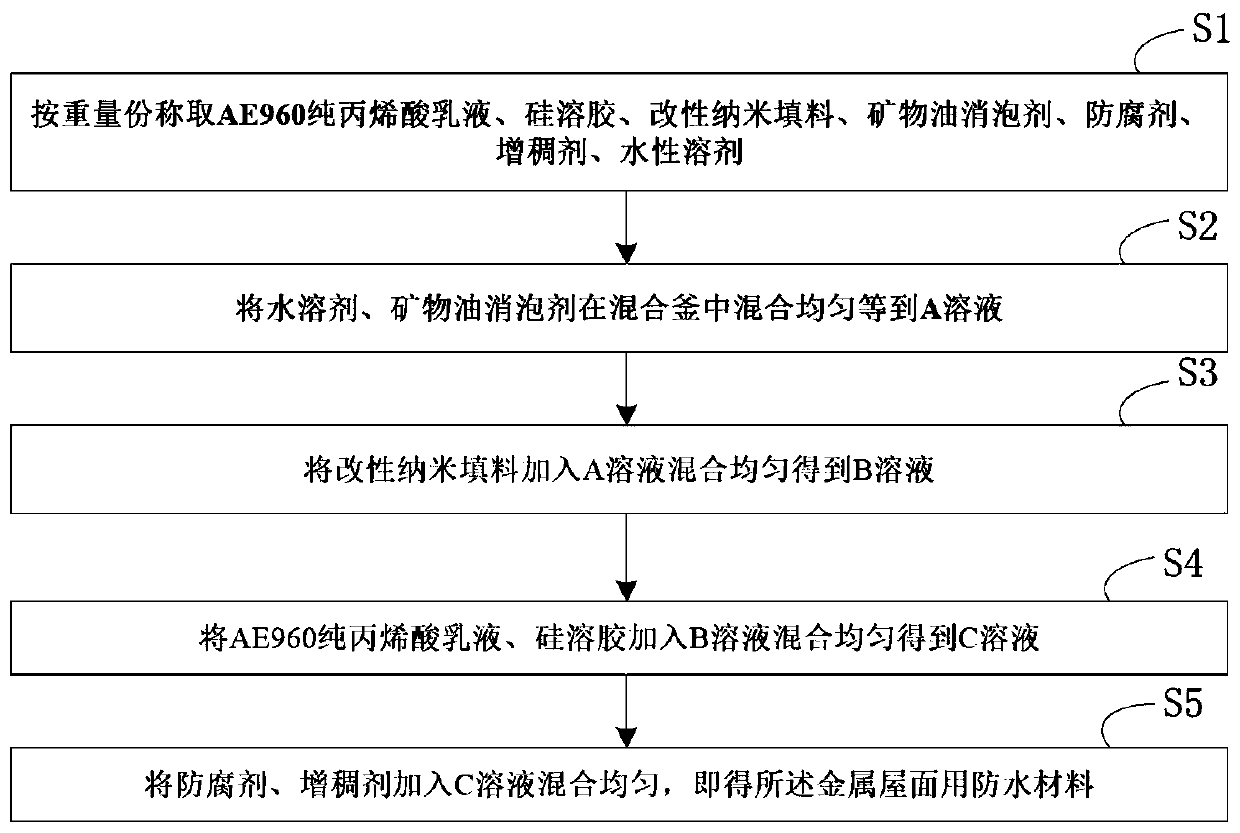

[0025] The preparation method of embodiment 1-5 metal roofing waterproof material comprises the following steps:

[0026] 1) Weigh AE960 pure acrylic acid emulsion, silica sol, modified nano filler, mineral oil defoamer, preservative, thickener, water-based solvent by weight;

[0027] 2) Mix the water solvent and mineral oil defoamer in the mixing kettle until the A solution is obtained;

[0028] 3) adding the modified nano filler to the A solution and mixing evenly to obtain the B solution;

[0029] 4) Add AE960 pure acrylic acid emulsion and silica sol to B solution and mix evenly to obtain C solution;

[0030] 5) Add antiseptic and thickener to solution C and mix evenly to obtain the waterproof material for metal roofing.

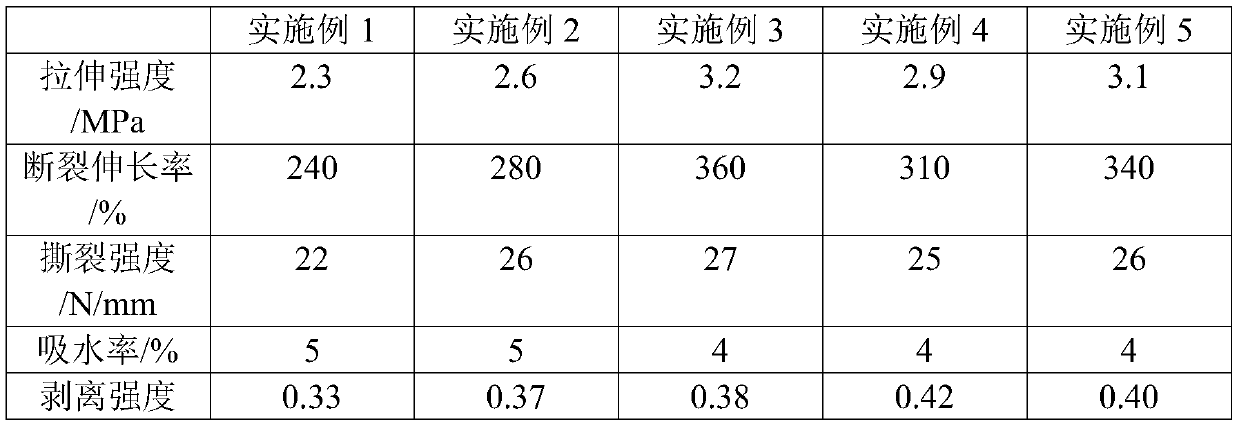

Embodiment 1

[0032] A waterproof material for metal roofing, comprising the following components in parts by weight: 430 parts of AE960 pure acrylic emulsion, 100 parts of silica sol, 400 parts of modified nano filler, 5 parts of mineral oil defoamer, 1.5 parts of benzimidazole, hydroxy 1.2 parts of methyl cellulose, 85 parts of ethanol.

Embodiment 2

[0034] A waterproof material for metal roofing, comprising the following components in parts by weight: 440 parts of AE960 pure acrylic acid emulsion, 110 parts of silica sol, 410 parts of modified nano filler, 5.2 parts of mineral oil defoamer, 1,2-benzisothiazole 1.6 parts of lin-3-one, 1.3 parts of hydroxyethyl cellulose, and 88 parts of acetone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com