Modified polyacrylonitrile ultra-filtration membrane, preparation method and application

A polyacrylonitrile and ultrafiltration membrane technology, which is applied in ultrafiltration, chemical instruments and methods, and membranes, can solve the problems of low internal structure order and regularity, affecting membrane water flux, and low service life. , to achieve the effect of improving anti-pollution performance, improving hydrophilicity and optimizing overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

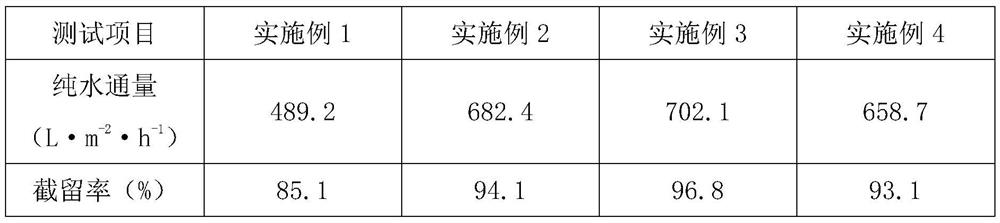

Embodiment 1

[0034] (1) Weigh 255g of N-N dimethylformamide and 45g of polyacrylonitrile, pour N-N dimethylformamide into a three-necked flask, add the rotor, slowly add polyacrylonitrile while stirring, and continue stirring until the polyacrylonitrile Nitrile is completely dissolved;

[0035] (2) Weigh 10.8g of ammonium chloride and 11.7g of sodium azide, add ammonium chloride and sodium azide in the three-necked flask successively, place the three-necked flask in the oil bath, and set the temperature of the oil bath to When the temperature is 120°C, one port is plugged with a plug, and the other port is sealed with a balloon. When the temperature rises to 120°C, stir for another 30 minutes, then leave the oil bath for 1.5 hours, and cool to 40°C;

[0036] (3) Measure 60 mL of hydrochloric acid and 550 mL of deionized water (excessive hydrochloric acid), pour the deionized water into a 1000 mL beaker, pour in the hydrochloric acid while stirring, and prepare a mixed solution;

[0037] (...

Embodiment 2

[0040]Weigh 56.6g of N-N dimethylformamide, 10g of polyacrylonitrile-grafted tetrazole prepared in Example 1, pour N-N dimethylformamide into a three-necked flask, add the rotor to stir, and then add the mixture prepared in Example 1 The polyacrylonitrile-grafted tetrazole, continue to stir until dissolved. Weigh 3.2 g of potassium carbonate, slowly add it to the above-mentioned three-necked flask, stopper one end tightly, and seal the other end with a balloon, put the three-necked flask into an oil bath, set the temperature of the oil bath to 60°C, and stir for about 2 hours. Weigh 3.33 mL of ethyl iodide, pour ethyl iodide into a three-necked flask, stir for 24 hours, and cool to 40°C. Slowly pour the mixed solution prepared in step (3) of Example 1 into the three-necked flask. Do not pour it too quickly, otherwise a 'bun' will be formed. Stir while pouring. After the poured solution is precipitated, repeat the above process until all precipitated. If the solution no longe...

Embodiment 3

[0042] Weigh 56.6g of N-N dimethylformamide, 10g of polyacrylonitrile-grafted tetrazole prepared in Example 1, pour N-N dimethylformamide into a three-necked flask, add the rotor to stir, and then add the mixture prepared in Example 1 The polyacrylonitrile-grafted tetrazole, continue to stir until dissolved. Weigh 3.2 g of potassium carbonate, slowly add it to the above-mentioned three-necked flask, stopper one end tightly, and seal the other end with a balloon, put the three-necked flask into an oil bath, set the temperature of the oil bath to 60°C, and stir for about 2 hours. Weigh 3.33 g of iodoacetic acid, pour the iodoacetic acid into a three-necked flask, stir for 24 hours, and cool to 40°C. Slowly pour the mixed solution prepared in step (3) of Example 1 into the three-necked flask. Do not pour it too quickly, otherwise a 'bun' will be formed. Stir while pouring. After the poured solution is precipitated, repeat the above process until all precipitated. If the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com