Halogen-containing flame-retardant nylon material with ultrahigh fluidity and high CTI and preparation method thereof

A flame-retardant nylon, ultra-high technology, applied in the field of ultra-high flow, high CTI halogen-containing flame-retardant nylon materials for electric vehicle connectors and its preparation, can solve problems such as high processing temperature, low CTI value, and reduced mechanical properties. Achieve the effects of reducing the amount of flame retardant, increasing the CTI value, and improving the flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A method for preparing an ultra-high flow and high CTI halogen-containing flame-retardant nylon material, the specific steps are as follows:

[0042] (1) Weigh PA66, PA6, polystyrene bromide, antimony trioxide, zirconium hydrogen phosphate and cadmium oxide, after mixing in a high-speed mixer, add it from the main feeding port of the twin-screw extruder; The rotating speed is 180 rpm, and the mixing time is 8 minutes;

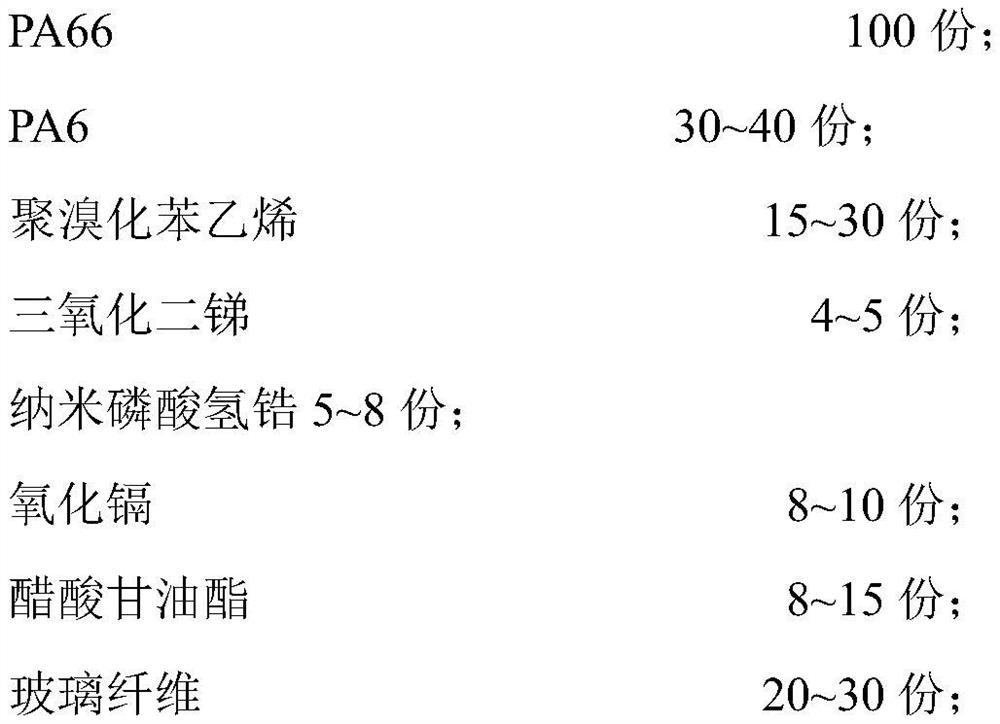

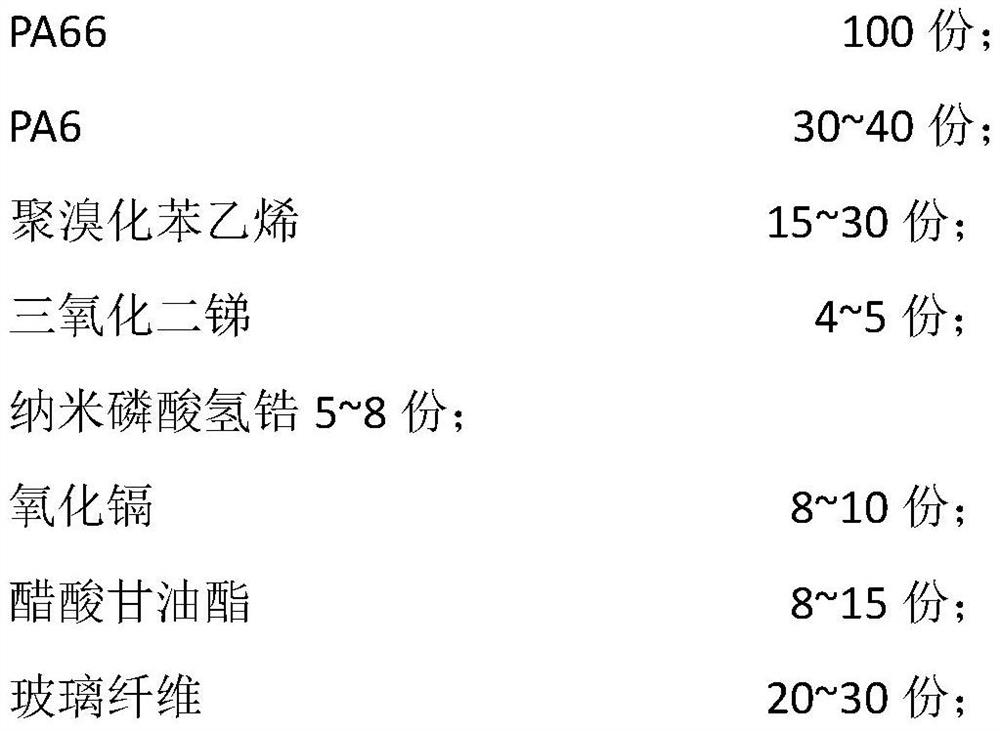

[0043] Wherein the parts by weight of each component are as follows:

[0044] PA66 100 copies;

[0045] PA6 30 copies;

[0046] 15 parts of polybrominated styrene;

[0047] 4 parts of antimony trioxide;

[0048] 5 parts of nano zirconium hydrogen phosphate;

[0049] 8 parts of cadmium oxide;

[0050] 8 parts of glyceryl acetate;

[0051] 20 parts of glass fiber;

[0052] The glass fiber is an alkali-free chopped fiber (ECS301CL-3-E) with a diameter of 7 μm treated with a silane coupling agent (γ-glycidyl ether propyl trimethoxysilane);

[0053] (...

Embodiment 2

[0057] A method for preparing an ultra-high flow and high CTI halogen-containing flame-retardant nylon material, the specific steps are as follows:

[0058] (1) Weigh PA66, PA6, polystyrene bromide, antimony trioxide, zirconium hydrogen phosphate and cadmium oxide, after mixing in a high-speed mixer, add it from the main feeding port of the twin-screw extruder; The rotating speed is 180 rpm, and the mixing time is 8 minutes;

[0059] Wherein the parts by weight of each component are as follows:

[0060] PA66 100 copies;

[0061] PA6 33 copies;

[0062] 18 parts of polybrominated styrene;

[0063] 4 parts of antimony trioxide;

[0064] 5 parts of nano zirconium hydrogen phosphate;

[0065] 8 parts of cadmium oxide;

[0066] 9 parts of glyceryl acetate;

[0067] 20 parts of glass fiber;

[0068] The glass fiber is an alkali-free chopped fiber (ECS301CL-3-E) with a diameter of 7 μm treated with a silane coupling agent (γ-glycidyl ether propyl trimethoxysilane);

[0069] ...

Embodiment 3

[0073] A method for preparing an ultra-high flow and high CTI halogen-containing flame-retardant nylon material, the specific steps are as follows:

[0074] (1) Weigh PA66, PA6, polystyrene bromide, antimony trioxide, zirconium hydrogen phosphate and cadmium oxide, after mixing in a high-speed mixer, add it from the main feeding port of the twin-screw extruder; The rotating speed is 200 rpm, and the mixing time is 8 minutes;

[0075] Wherein the parts by weight of each component are as follows:

[0076] PA66 100 copies;

[0077] PA6 35 copies;

[0078] 21 parts of polybrominated styrene;

[0079] 4 parts of antimony trioxide;

[0080] 5 parts of nano zirconium hydrogen phosphate;

[0081] 8 parts of cadmium oxide;

[0082] 10 parts of glyceryl acetate;

[0083] 25 parts of glass fiber;

[0084] The glass fiber is an alkali-free chopped fiber (ECS301CL-3-E) with a diameter of 7 μm treated with a silane coupling agent (γ-glycidyl ether propyl trimethoxysilane);

[0085]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com