Low-surface-energy organic silicon protective coating and preparation method thereof

A protective coating and low surface energy technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems affecting the safety of power grid operation, large leakage current, and accelerated corrosion of metal bearing parts and reinforced concrete. To achieve the effect of maintaining the marking specification and overall image, reducing the corrosion rate, excellent hydrophobicity and anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

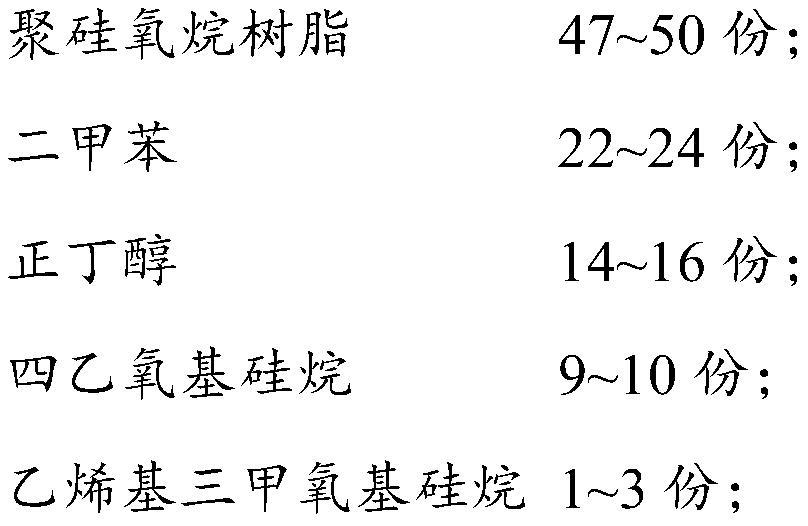

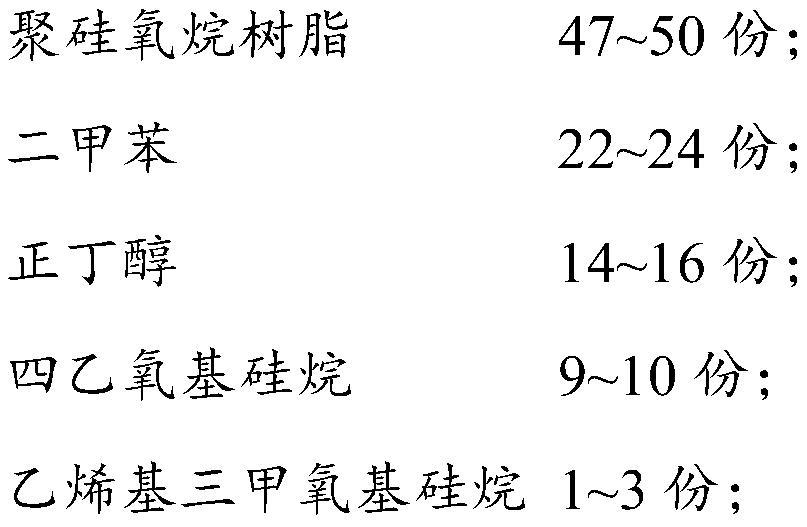

[0033] The present embodiment provides a kind of low surface energy organosilicon protective coating, and this coating comprises component A and component B, wherein the mass ratio of component A and component B is A component: B component=7: (2~ 4). The A component is mixed by the following mass percentages: polysiloxane resin 47-50%; vinyltrimethoxysilane 1-3%; tetraethoxysilane 9-10%; xylene 22- 24%; n-butanol 14-16%; curing accelerator 2-3%; defoamer 0.3-0.6%; B component consists of 85-87% tetraethoxysilane; Ethoxysilane; mixed with 3-7% n-Butanol.

[0034] The Si-O-Si bond length of siloxane is longer, the bond angle is larger, and it is easy to rotate. Its steric hindrance to the rotation of the side chain is small, the molecular volume is large and the cohesive energy density is low, which reduces the steric hindrance, making the side chain The free rotation of the base is relatively easy, and it has the characteristics of low glass transition temperature, low surfac...

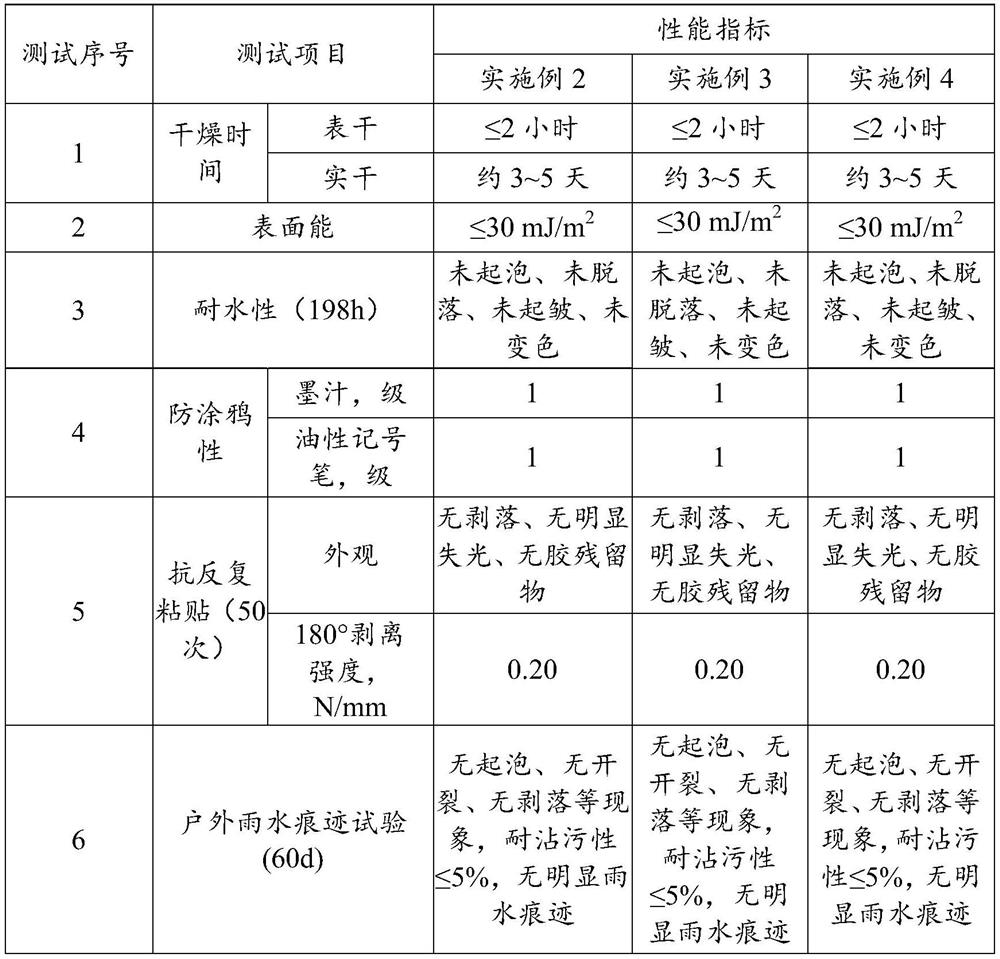

Embodiment 2

[0038] A kind of preparation method of low surface energy organosilicon protective coating is as follows:

[0039] Weigh 47.5g polysiloxane resin, 23.5g xylene, 15g n-butanol, 1.5g vinyltrimethoxysilane, 9.5g tetraethoxysilane, 0.5g defoamer, 2.5g curing accelerator, add In the dispersing container, disperse at the speed of 500r / min for 25 minutes to form a uniform dispersion; filter and package the slurry prepared above with a 200-mesh filter to obtain component A.

[0040] Weigh 85g of tetraethoxysilane, 10g of triethoxysilane, and 5g of n-butanol into the dispersion container, and disperse at a speed of 500r / min for 30 minutes to form a uniform dispersion; The B component is obtained by filtering and packaging with a filter screen. The distribution ratio of the two groups is used in combination according to the mass ratio of component A: component B = 7:3.

Embodiment 3

[0042] A kind of preparation method of low surface energy organosilicon protective coating is as follows:

[0043]Take by weighing 50g polysiloxane resin, 22g dimethylbenzene, 14g n-butanol, 2g vinyltrimethoxysilane, 9g tetraethoxysilane, 0.4g defoamer, 2g curing accelerator, add in dispersion container, in Disperse at a speed of 800r / min for 20 minutes to form a uniform dispersion; filter and package the slurry prepared above with a 150-mesh filter to obtain component A.

[0044] Weigh 87g of tetraethoxysilane, 9g of triethoxysilane, and 6g of n-butanol into the dispersion container, and disperse at a speed of 300r / min for 35 minutes to form a uniform dispersion; The B component is obtained by filtering and packaging with a filter screen. The distribution ratio of the two groups is used in conjunction with the mass ratio of component A: component B = 7:3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com