A kind of preparation method of aldehyde removal catalyst

A technology of catalyst and complexing agent, which is applied in the field of preparation of aldehyde-removing catalysts, can solve the problems of reduced effective utilization of precious metals, no improvement in the dispersion of metal oxides, no strong interaction, etc., and achieves hydrogen-saving high-temperature reduction activation process , promote adsorption and further oxidation, and enhance the effect of electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

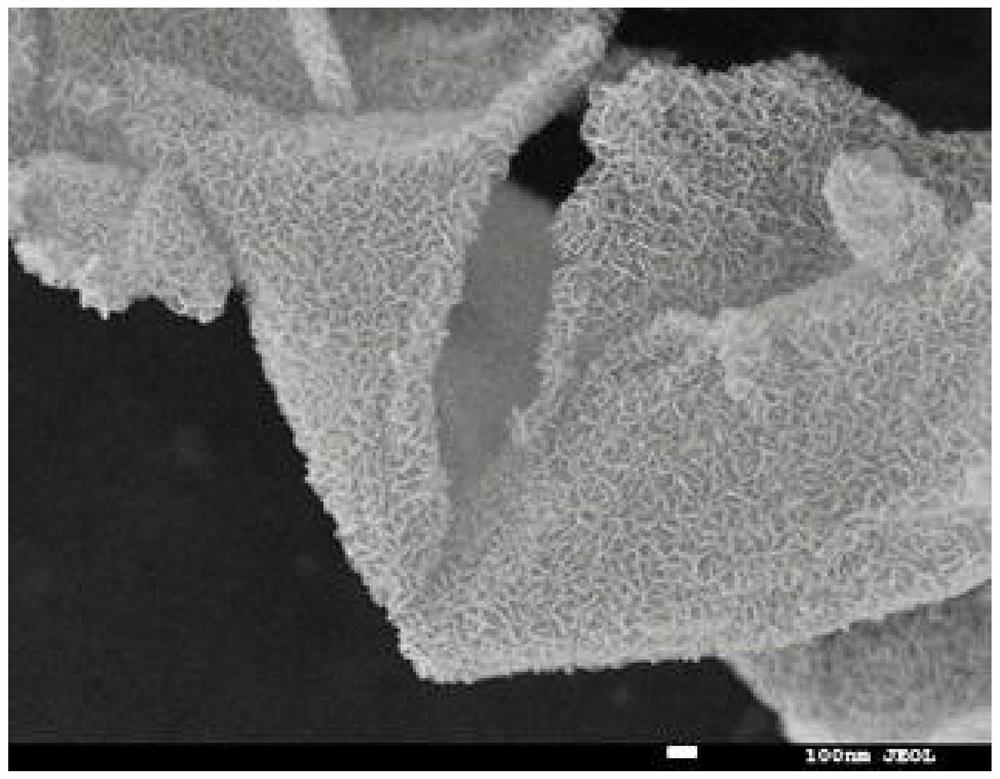

Image

Examples

Embodiment 1

[0026] The preparation method of the aldehyde removal catalyst of the present embodiment comprises the steps:

[0027] (1) ultrasonically disperse 10 mg of graphene oxide in 30 mL of deionized water, then slowly dropwise add aqueous sodium carbonate solution therein, adjust the pH value of the solution to 9-10, and record it as solution A;

[0028] (2) Disperse 1.45g of nickel nitrate hexahydrate and 0.74g of sodium citrate in 30mL of deionized water, stir for a period of time, then add 0.005g of chloroplatinic acid solution, continue stirring evenly, and record it as solution B;

[0029] (3) Slowly add solution B to solution A, stir evenly to form solution C;

[0030] (4) Transfer solution C into a 100mL hydrothermal kettle and keep it warm at 120°C for 12h;

[0031] (5) The heated solution C obtained in step (4) is subjected to solid-liquid separation through a filter screen, and the separated solid matter is freeze-dried for 24 hours;

[0032] (6) Calcining the dried soli...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is that step (6) is different:

[0035] In this example, the dried solid matter obtained in step (5) was calcined at 500° C. for 2 hours in a nitrogen atmosphere, and the heating rate was set at 3° C. / min and finally raised to 500° C. to obtain the catalyst.

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 1 is that step (6) is different:

[0038] In this example, the dried solid matter obtained in step (5) was calcined at 200° C. for 2 h in a nitrogen atmosphere, and the heating rate was set at 3° C. / min and finally raised to 200° C. to obtain the catalyst. That is, the nitrogen roasting temperature is 200 degrees. At this time, platinum mostly exists in the form of salt or oxide, and platinum simple substance plays a major role in catalytic activity in formaldehyde oxidation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com