Method for preparing high-purity manganese sulfate by reducing and leaching pyrolusite from rotary kiln slag

A technology of rotary kiln and manganese sulfate, which is applied in the field of manganese sulfate, can solve the problems that steel plants are difficult to accept, and achieve the effects of cost saving, high iron content and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

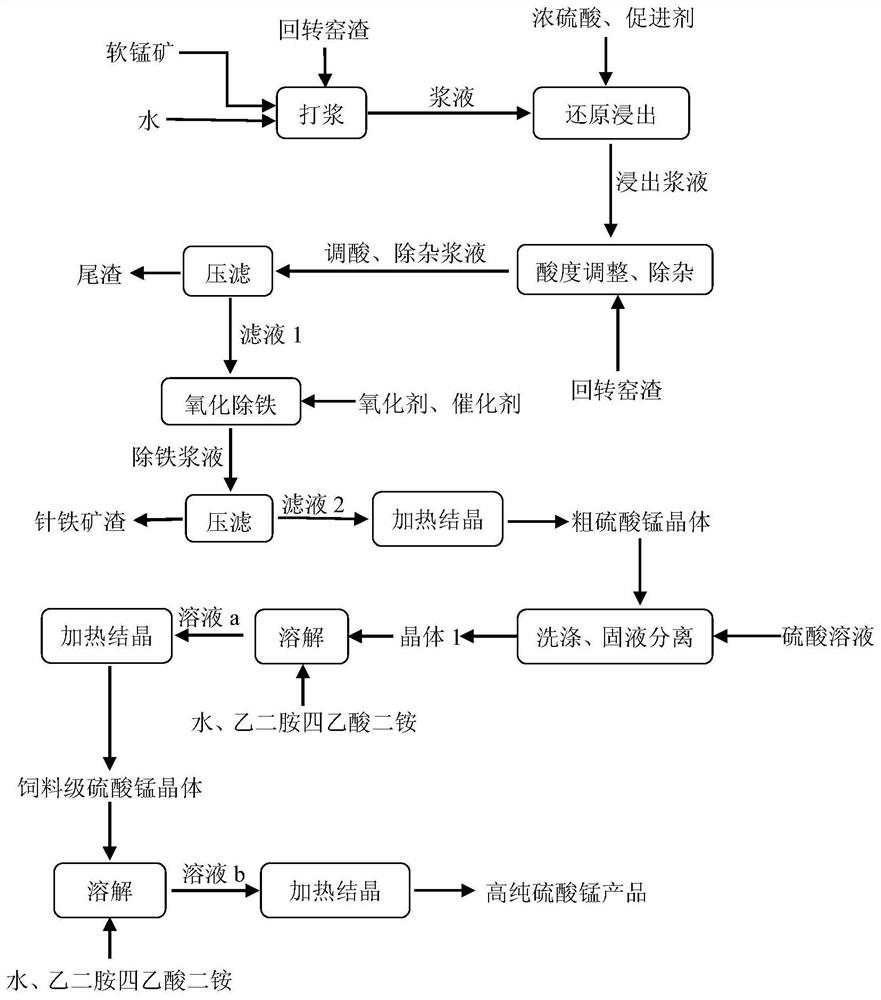

[0051] The method for preparing high-purity manganese sulfate by reducing and leaching pyrolusite with rotary kiln slag comprises the following steps:

[0052] The main component detection of the pyrolusite involved in the present embodiment is as follows:

[0053] main ingredient MnO 2

Fe SiO 2

C Al 2 o 3

Ca Mg K content(%) 67.41 5.96 9.37 6.18 3.68 0.88 0.49 1.15 chemical composition Na Ni co Cr Pb Cd Zn Cu content(%) 0.84 0.031 0.011 0.018 <0.005

<0.001

0.02 0.0072

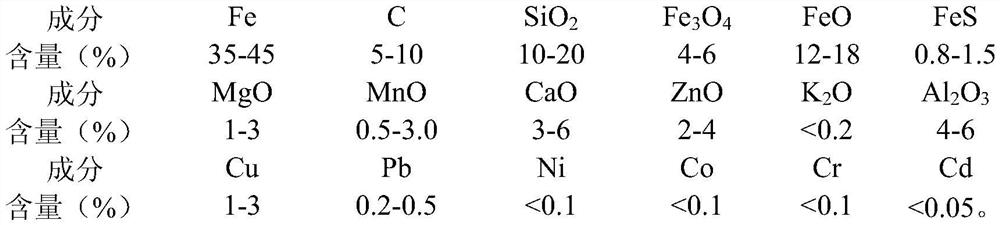

[0054] The detection of the main components of the rotary kiln slag involved in this embodiment is as follows:

[0055] main ingredient Fe C SiO 2

Fe 3 o 4

FeO FeS content(%) 43.34 8.10 14.33 4.67 14.11 1.46 main ingredient MgO MnO CaO ZnO K 2 o

Al 2 o 3

content(%) 2.37 1.39 4.21 3.48 0.12 4.76 main ingredient Cu Pb Ni co Cr C...

Embodiment 2

[0071] The method for preparing high-purity manganese sulfate by reducing and leaching pyrolusite with rotary kiln slag comprises the following steps:

[0072] The chemical composition data of the pyrolusite of the present embodiment and the rotary kiln slag are identical with embodiment 1;

[0073] 1) Beating: Mix the pyrolusite and rotary kiln slag that have passed through a 100-mesh sieve at a mass ratio of 1:2 to obtain a mixture, and put the mixture and water into the stirring tank at a solid-to-liquid mass ratio of 1:2 for beating get the slurry;

[0074] 2) add promotor in the slurry that upward step obtains, after stirring evenly, add dropwise the concentrated sulfuric acid that mass content is 98% to carry out reduction leaching reaction, the addition of promotor is 3% of slurry quality, controls the adding speed of vitriol oil so that The reaction pH value is between 0-1.5, the reaction temperature is 70-80°C, the reaction time is 3h, and the leaching slurry is obta...

Embodiment 3

[0088] The method for preparing high-purity manganese sulfate by reducing and leaching pyrolusite with rotary kiln slag comprises the following steps:

[0089] The chemical composition data of the pyrolusite of the present embodiment and the rotary kiln slag are identical with embodiment 1;

[0090] 1) Beating: Mix the pyrolusite and rotary kiln slag that have passed through a 100-mesh sieve at a mass ratio of 1:1 to obtain a mixture, and put the mixture and water into the stirring tank at a solid-to-liquid mass ratio of 1:1 for beating get the slurry;

[0091] 2) add promotor in the slurry that upward step obtains, after stirring evenly, add dropwise the concentrated sulfuric acid that mass content is 98% and carry out reduction leaching reaction, the addition of promotor is 5% of slurry quality, controls the adding speed of vitriol oil so that The reaction pH value is between 0-1.5, the reaction temperature is 90-100°C, the reaction time is 2h, and the leaching slurry is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com