Cobalt-free positive electrode material and preparation method thereof

A cathode material and cathode technology, applied in the field of cobalt-free cathode materials and their preparation, can solve the problems of practical application limitations, large cobalt-free materials, large expansion force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

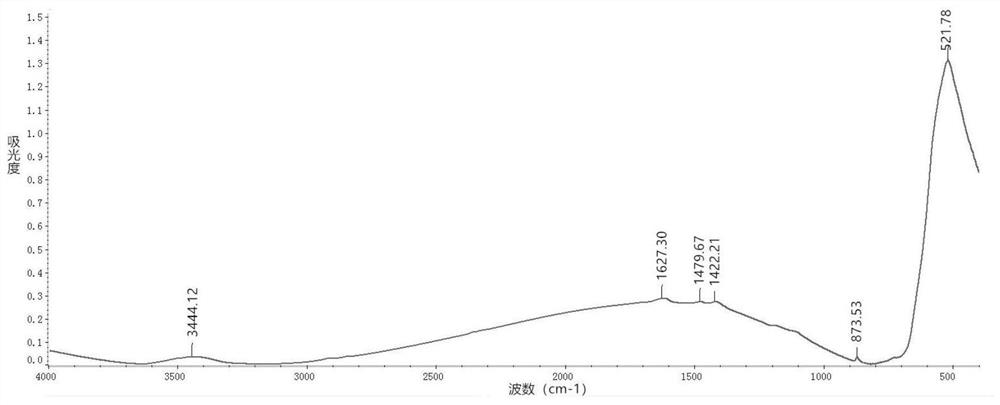

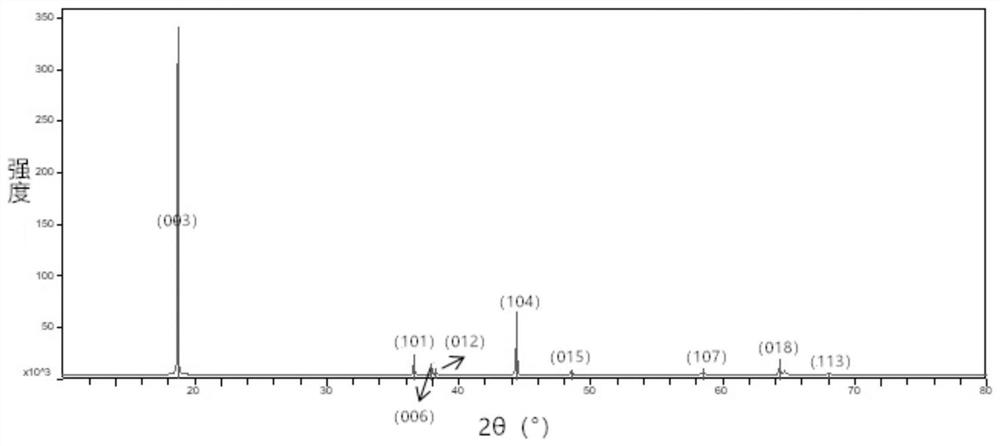

[0055] This embodiment provides a method for preparing a cobalt-free positive electrode material, the preparation method comprising the following steps:

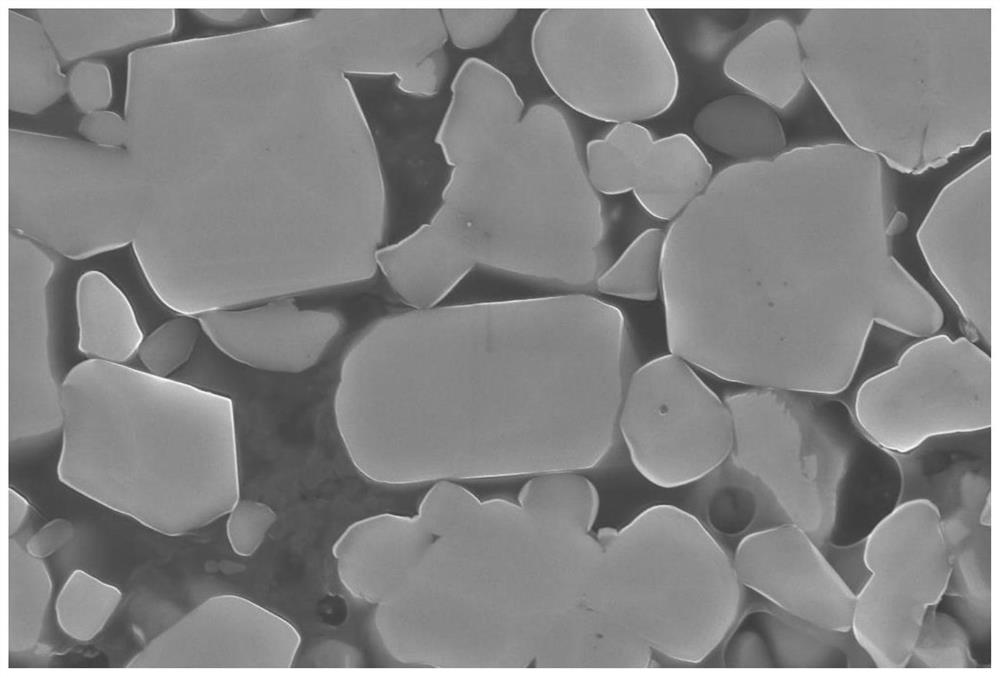

[0056] (1) Lithium hydroxide, precursor Ni 0.5 mn 0.5 (OH) 2 and WO 3 After mixing, put it in an oxygen atmosphere, and sinter at 600°C for 15 hours to obtain a block material. The molar ratio of Li / (Ni+Mn) is 0.95 for mixing, and the D50 particle size of the precursor is 2 μm; The material is pulverized to obtain cobalt-free cathode particles with a particle size of 2 μm;

[0057] (2) Cobalt-free positive electrode particles, magnesium oxide and graphite are mixed and then dry coated, the quality of magnesium oxide is 0.1wt% of the mass of cobalt-free positive electrode particles, and the mass ratio of graphite to magnesium oxide is 1:10;

[0058] (3) Heating the coated cobalt-free cathode particles at 350°C for 10 hours to obtain a cobalt-free cathode material, and then sifting the cobalt-free cathode material with a p...

Embodiment 2

[0060] This embodiment provides a method for preparing a cobalt-free positive electrode material, the preparation method comprising the following steps:

[0061] (1) Lithium carbonate, precursor Ni 0.6 mn 0.4 (OH) 2 and Nb 2 o 5 After mixing, put it in an air atmosphere, and sinter at 680°C for 13 hours to obtain a block material. The molar ratio of Li / (Ni+Mn) is 0.96 for mixing, and the D50 particle size of the precursor is 2.5 μm; The powdery material was crushed to obtain cobalt-free positive electrode particles with a particle size of 2.6 μm;

[0062] (2) Cobalt-free positive electrode particles, titanium oxide and polyethylene are mixed and then dry-coated, the mass of titanium oxide is 0.5wt% of the mass of cobalt-free positive electrode particles, and the mass ratio of polyethylene to titanium oxide is 1:200;

[0063] (3) Heating the coated cobalt-free cathode particles at 450°C for 9 hours to obtain a cobalt-free cathode material, followed by 120Hz airflow classif...

Embodiment 3

[0065] This embodiment provides a method for preparing a cobalt-free positive electrode material, the preparation method comprising the following steps:

[0066] (1) Lithium carbonate, precursor Ni 0.7 mn 0.3 (OH) 2 and ZrO 2 After mixing, put it in an oxygen atmosphere, and sinter at 760°C for 10 hours to obtain a block material. The molar ratio of Li / (Ni+Mn) is 0.97 for mixing, and the D50 particle size of the precursor is 3 μm; The material is crushed to obtain cobalt-free positive electrode particles with a particle size of 3.2 μm;

[0067] (2) Cobalt-free positive electrode particles, zirconia and polyvinylpyrrolidone are mixed and then dry-coated; the quality of zirconia is 1.2wt% of the mass of cobalt-free positive electrode particles, and the mass ratio of polyvinylpyrrolidone to zirconia is 1: 500;

[0068] (3) Heating the coated cobalt-free cathode particles at 550°C for 8 hours to obtain a cobalt-free cathode material, and then sifting through a 140Hz airflow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com