Steel wet desulphurization wastewater treatment system and method

A wastewater treatment system, wet desulfurization technology, applied in metallurgical wastewater treatment, gaseous effluent wastewater treatment, water/sewage treatment, etc., can solve secondary pollution, can not completely realize zero discharge of desulfurization wastewater pollutants, wastewater or crystallization Solve problems such as complex salt composition, and achieve the effect of reducing the operating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

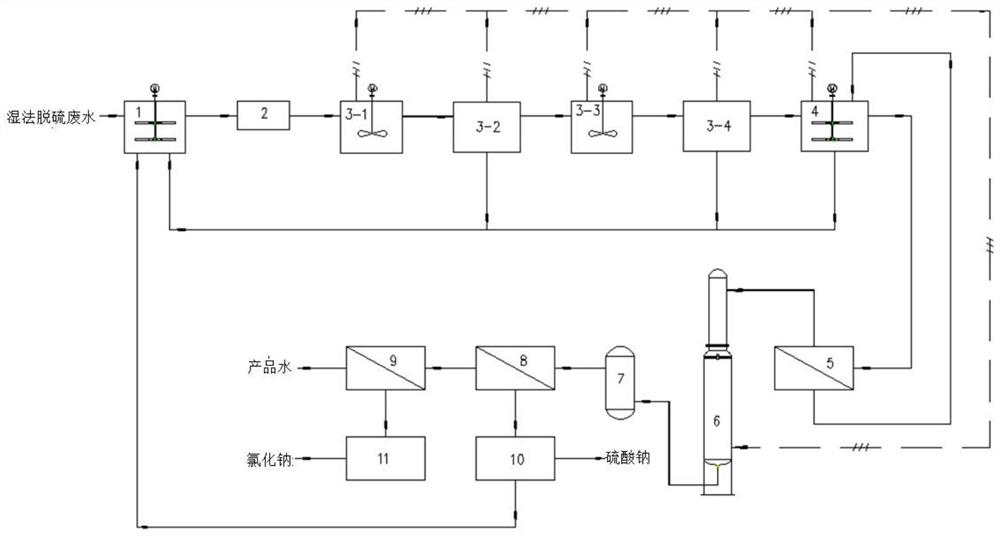

[0085]figure 2A structure of a steel wet desulfurization wastewater treatment system for this embodiment is shown schematically. Such asfigure 2As shown, the system includes a wastewater collecting apparatus, a plate frame filter device, a secondary chemical defective device, a concentrated precipitation apparatus, a filtration device, a deammorer device, a softening apparatus, a softening apparatus, a softening apparatus, a softening apparatus, a softening apparatus, a softening device, a filter device, a softening device, a filter device And film treatment device / electrodialysis device. Specifically, the first inlet with stirred wastewater collecting device 1 is used to input wet desulfurization wastewater, and the first outlet of the wastewater collecting device 1 is connected to the plate frame filter device 2, and the plate frame filter device 2 The first exit is connected to the first inlet of the first stage chemical reaction device 3-1, and the first exit of the first stag...

Embodiment 2

[0091]In this embodiment, the initial water quality of desulfurization wastewater is shown in Table 1:

[0092]Table 1 Desulfurization wastewater initial water quality

[0093]

[0094]

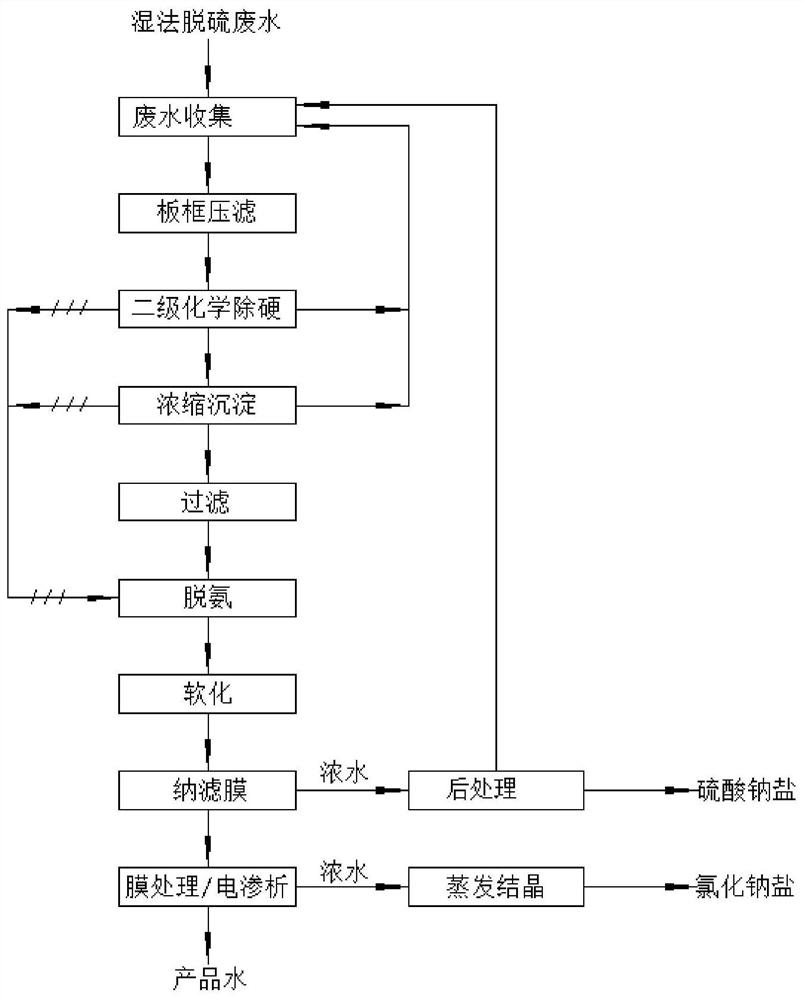

[0095]figure 1 The flow of the steel wet desulfurization wastewater treatment method in the present invention is shown schematically. Bonded belowfigure 1 Description of the processing method of this embodiment:

[0096]1) In the abandoned wastewater collecting device 1, the wastewater collecting apparatus 1 has solid-liquid separation in the wastewater collecting plate filter device 2, and obtains high salt wastewater and dry mud.

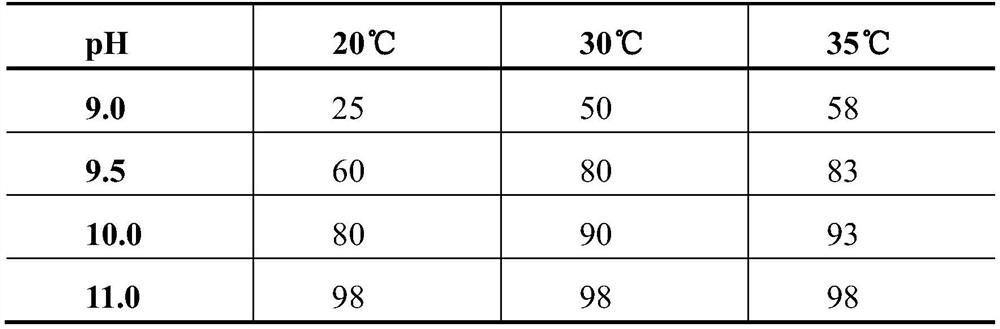

[0097]2) Putting the plate frame filter device 2 in step 1) contains high salt wastewater into the first stage chemical reaction device 3-1 (the first level chemical reaction device 3-1 is stirred, and the concentration 5 is added % Of the calcium hydroxide solution and concentration of 15% alkaline solution), adjusted to pH = 11.5; again into the first stage chemical precipitation appa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com