Covalent organic framework membrane with high rejection rate as well as raw material composition and preparation method thereof

A technology of covalent organic framework and raw material composition, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of covalent organic framework membrane affecting practical application value, difficulty in effectively retaining dyes, and large pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

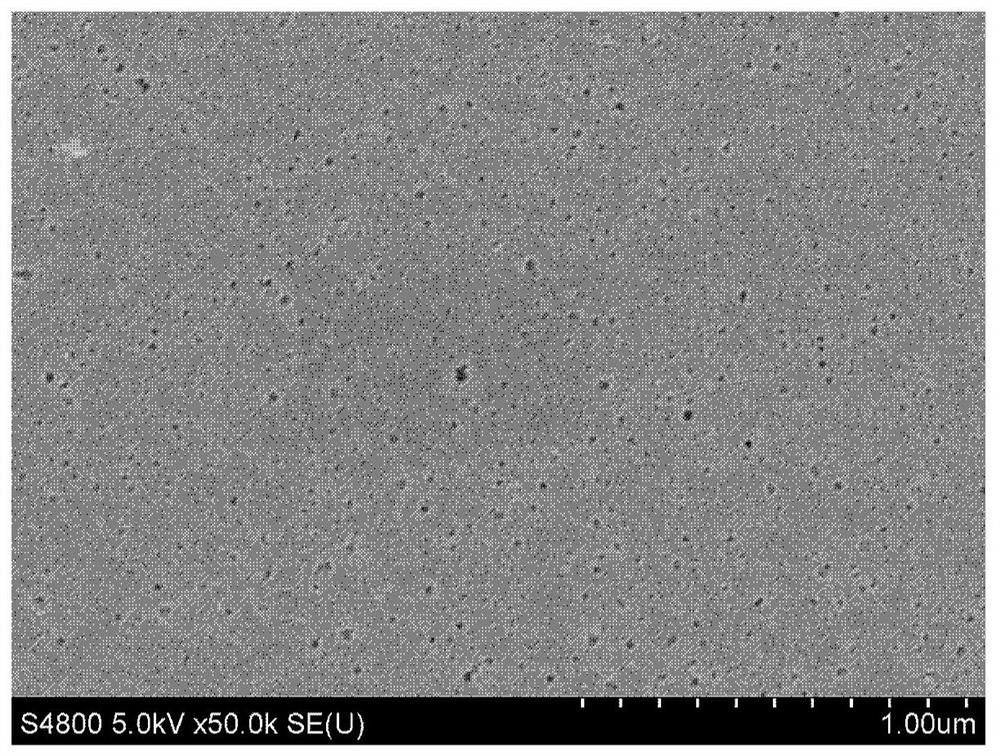

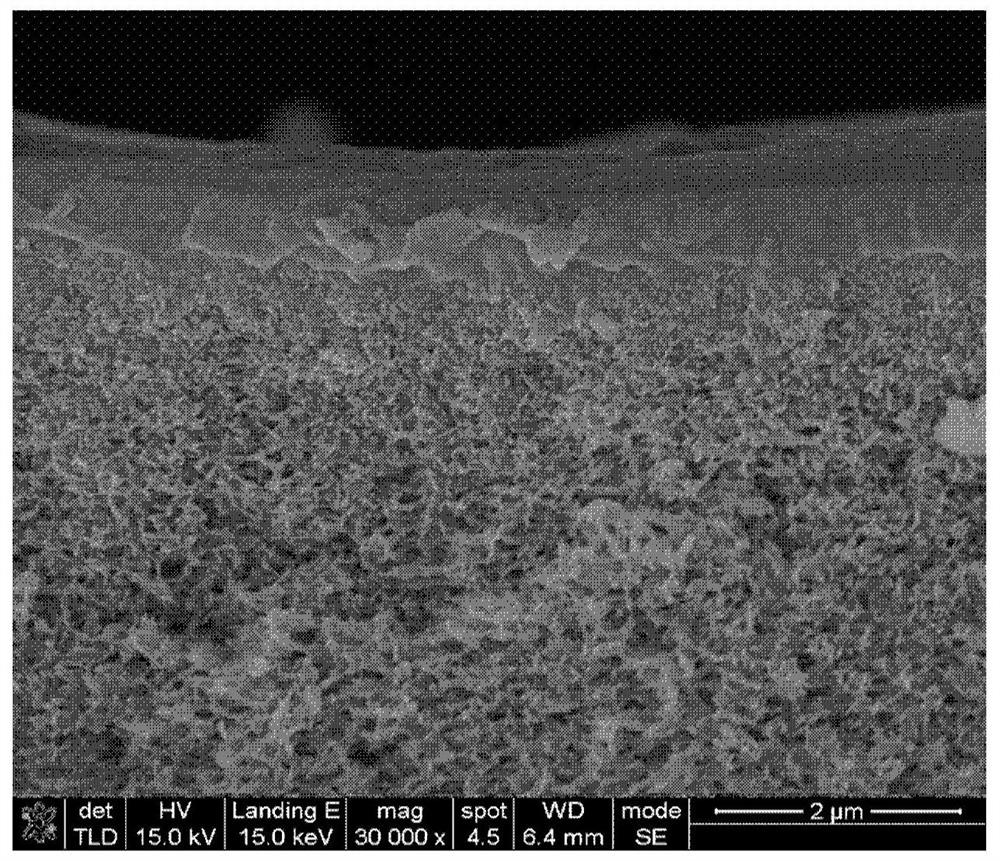

[0045] Prepare an aqueous solution containing 1% p-phenylenediamine and a small amount of glacial acetic acid, and adjust the pH value to 4 as an aqueous phase solution. Prepare 0.05% n-hexane solution of 1,3,5-trialdehyde phloroglucinol as the organic phase solution. Firstly, the aqueous phase solution was placed on the surface of the polyacrylonitrile support membrane, and after 60 seconds of adsorption, the excess solution was removed. Then, the organic phase solution was placed on the surface of the membrane, and after 120s of reaction, the excess solution was removed, and the unreacted monomer was washed away with n-hexane. Afterwards, the membrane was placed in a modified solution with a pH of 3 containing 0.5% aniline monomer, 0.2% ammonium persulfate, and a small amount of p-toluenesulfonic acid. After 2 hours of reaction, it was taken out and washed repeatedly with deionized water to prepare a high rejection rate. Covalent organic framework membranes.

[0046] After...

Embodiment 2

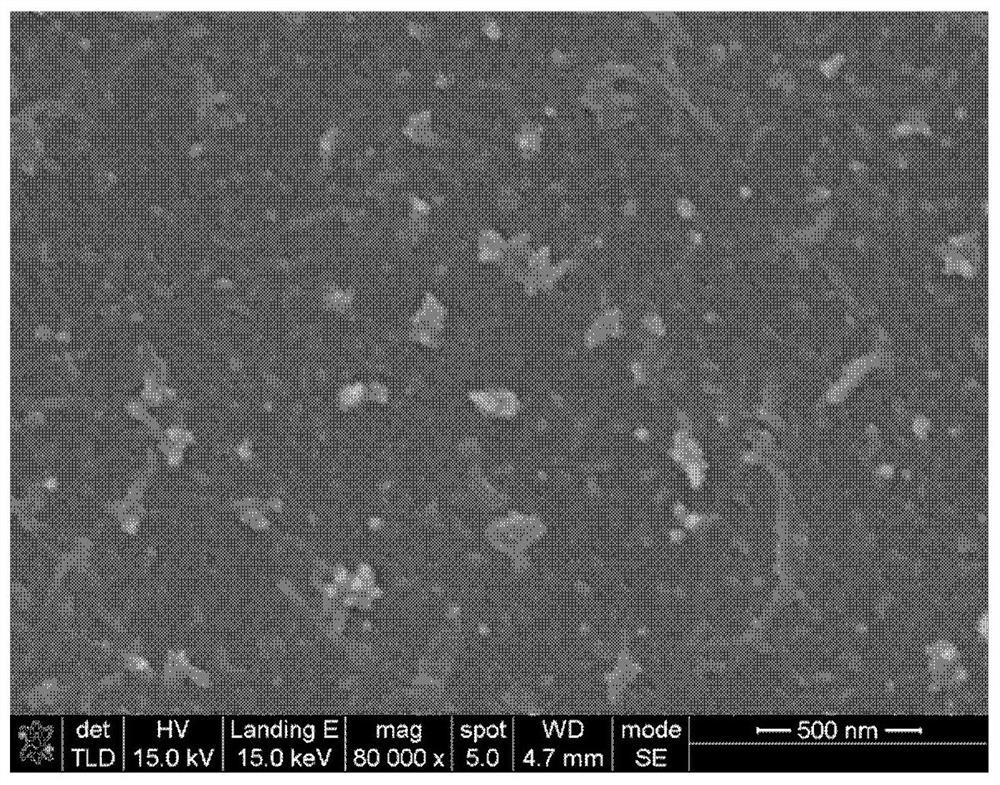

[0049] An aqueous solution containing 2% of 1,3,5-tris(4-aminophenyl)benzene and a small amount of hydrochloric acid was prepared, and the pH value was adjusted to 3 as an aqueous phase solution. Prepare 0.05% n-hexane solution of 1,3,5-trialdehyde phloroglucinol as the organic phase solution. Firstly, the aqueous phase solution was placed on the surface of the polyacrylonitrile support membrane, and after 60 seconds of adsorption, the excess solution was removed. Then, the organic phase solution was placed on the surface of the membrane, and after 240s of reaction, the excess solution was removed, and the unreacted monomer was washed away with n-hexane. Afterwards, the membrane was placed in a modified solution with a pH of 10 containing 2% dopamine monomer, 0.1% ammonium persulfate, and a small amount of tris(hydroxymethyl)aminomethane. After reacting for 5 hours, it was taken out and washed repeatedly with deionized water to prepare A high rejection covalent organic framew...

Embodiment 3

[0052] Prepare an aqueous solution containing 1% p-phenylenediamine and a small amount of p-toluenesulfonic acid, and adjust the pH value to 4 as an aqueous phase solution. A 0.05% cyclohexane solution of 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde was prepared as an organic phase solution. First, put the aqueous phase solution on the surface of the polysulfone support membrane, and remove the excess solution after adsorption for 100 seconds. Then, the organic phase solution was placed on the surface of the membrane, and after 120s of reaction, the excess solution was removed, and the unreacted monomer was washed away with cyclohexane. Afterwards, the membrane was placed in a modified solution with a pH of 2 containing 1.0% p-phenylenediamine monomer, 0.3% ammonium persulfate, and a small amount of hydrochloric acid. After reacting for 5 hours, it was taken out and washed repeatedly with deionized water to prepare a high rejection rate. Covalent organic framework membranes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com