High-throughput preparation method of monodisperse silicon dioxide microspheres

A monodisperse silica microsphere, silica technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of difficulty in forming monodisperse silica, wide particle size distribution, low mixing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

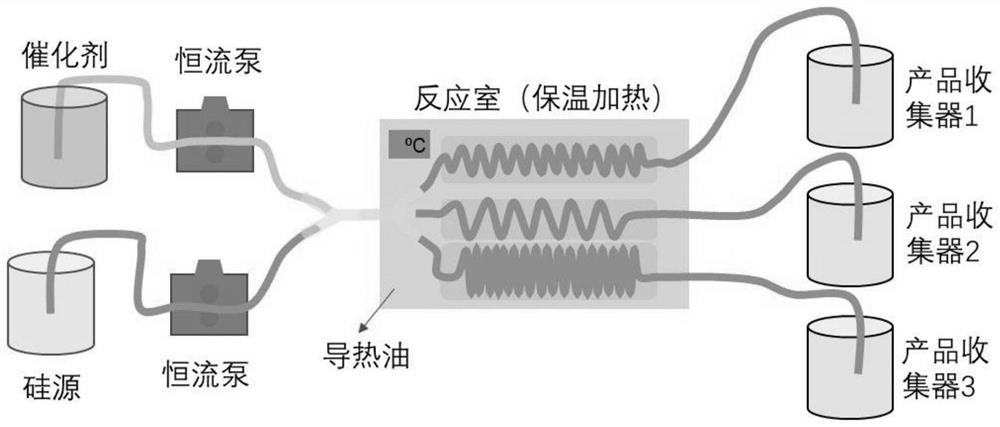

[0032] The high-throughput preparation method of monodisperse silica microspheres in this embodiment comprises the following steps:

[0033] Step 1. Disperse 20g of tetraethyl orthosilicate in 100g of isopropanol and stir evenly to obtain the first solution, wherein the mass ratio of tetraethyl orthosilicate to isopropanol is 0.2;

[0034] Step 2. Disperse 10g of 20wt% sodium hydroxide solution in 100g of deionized water and stir evenly to obtain a second solution, wherein the mass ratio of sodium hydroxide to deionized water is 0.1;

[0035] Step 3. the first solution is imported from one inlet port of the reaction chamber with 2ml / min, and the second solution is imported from the other inlet port of the reaction chamber with 3ml / min, and mixed rapidly;

[0036] Step 4. The above mixed solution passes through two spiral tubes, which are 120m long, 0.7mm internal diameter and 70m long, 1.2mm internal diameter spiral tubes. The spiral tubes are placed in a square tank at 40°C f...

Embodiment 2

[0040] The high-throughput preparation method of monodisperse silica microspheres in this embodiment comprises the following steps:

[0041] Step 1. Disperse 20g of methyl orthosilicate in 100g of ethanol, stir evenly to obtain the first solution, wherein the mass ratio of tetramethyl orthosilicate to ethanol is 0.2;

[0042] Step 2. Disperse 15g of 30wt% ammonia solution in 100g of deionized water and stir evenly to obtain a second solution, wherein the mass ratio of ammonia to deionized water is 0.15;

[0043]Step 3. The first solution is input from one inlet port of the reaction chamber with 1ml / min, and the second solution is imported from the other inlet port of the reaction chamber with 2ml / min, and mixed rapidly;

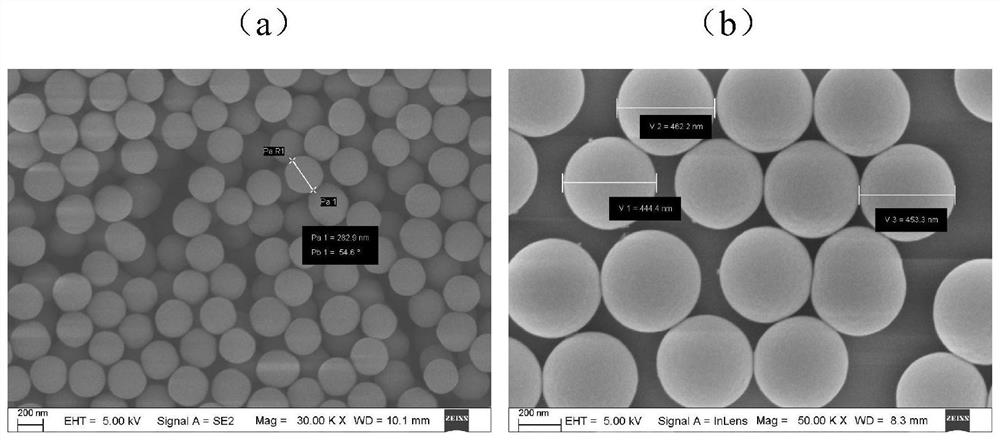

[0044] Step 4. The above mixed solution is carried out through two spiral tubes, which are 150m in length, 0.5mm in inner diameter and 90m in length, 1.0mm in inner diameter. The spiral tube is placed in a square tank at 30°C for reaction, and the reaction ti...

Embodiment 3

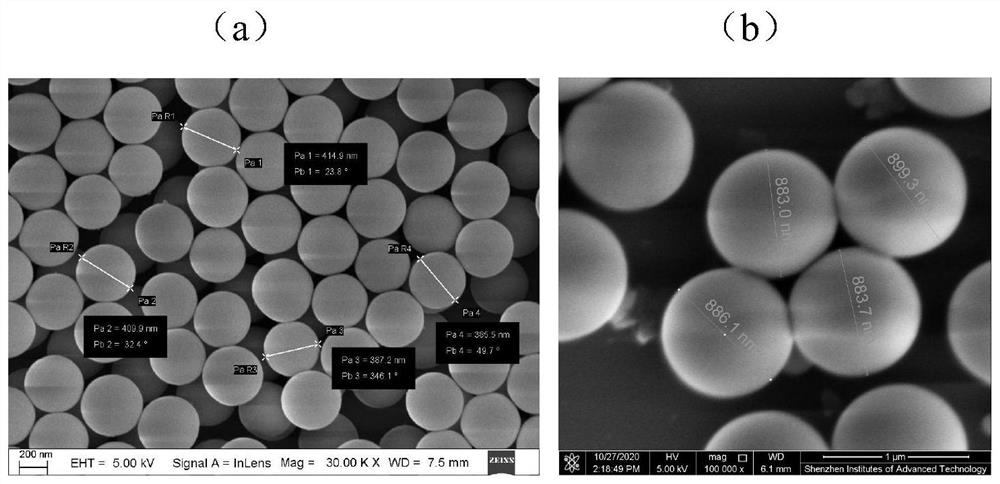

[0048] The high-throughput preparation method of monodisperse silica microspheres in this embodiment comprises the following steps:

[0049] Step 1. Disperse 10g of tetraethyl orthosilicate in 60g of ethanol, stir evenly to obtain the first solution, the mass ratio of tetraethyl orthosilicate to ethanol is 0.17;

[0050] Step 2. Disperse 10g of 20wt% ammonia solution in 100g of deionized water and stir evenly to obtain a second solution, wherein the mass ratio of ammonia to deionized water is 0.1;

[0051] Step 3. The first solution is imported from one inlet port of the reaction chamber at 0.5ml / min, and the second solution is imported from the other inlet port of the reaction chamber at 2ml / min, and mixed rapidly;

[0052] Step 4. The above mixed solution is carried out through two spiral tubes, which are 150m long, 0.5mm inner diameter and 30m long, 1.5mm inner diameter spiral tubes. The spiral tubes are placed in a square tank at 50°C for reaction, and the reaction time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com